we ensure reliability of your process

SMT Stencil Cleaning

Stencil cleaning is crucial in surface mount technology as it ensures accurate solder paste application, improves solder joint quality, reduces scrap and rework, prolongs stencil life, and ensures compliance with industry standards.

Stencil Technology

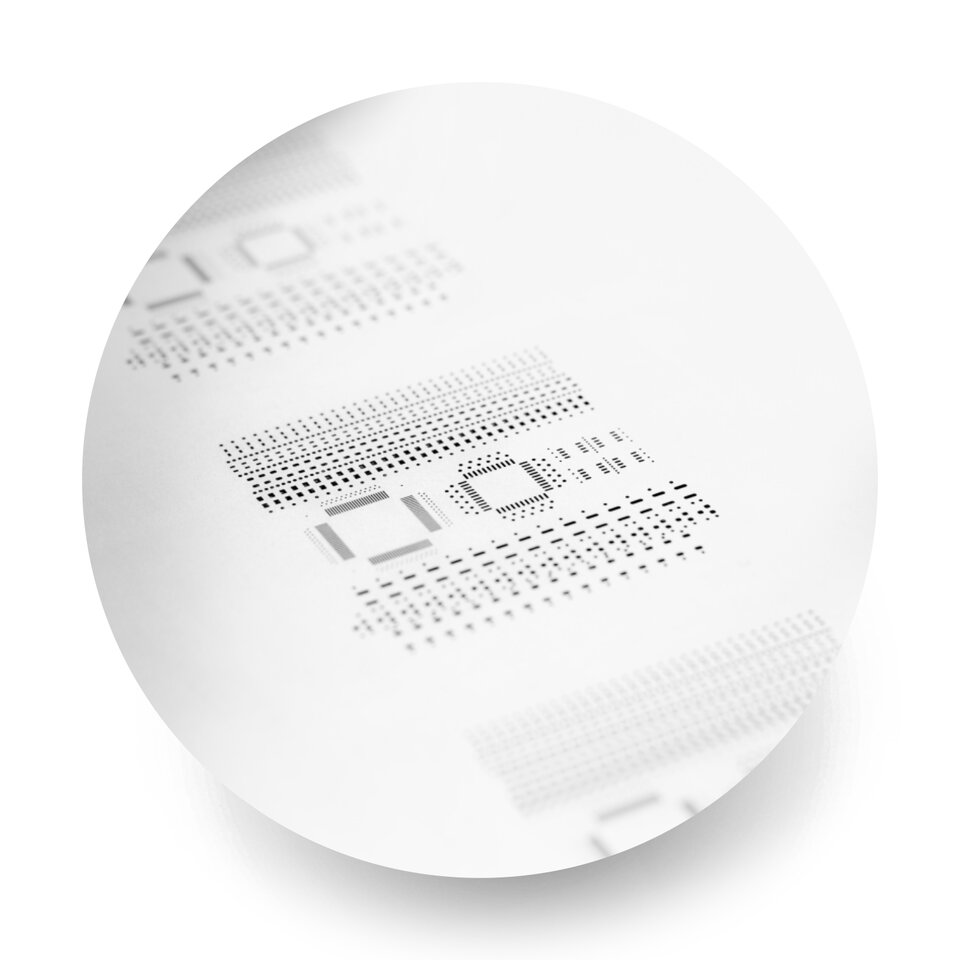

SMT stencil technology has advanced significantly over the years, with new materials, designs, and manufacturing processes improving the accuracy and efficiency of the process. These advances include:

-

Improved materials

-

Advanced designs

-

Innovative stencil technologies

Finding the right cleaning product for your application is critical. At ZESTRON, our high precision cleaning agents are powered by proprietary chemical technology. We work with all the industry leading stencil manufcaturers to deliver cleaning solutions compatible with the latest technilogical advancments.

Stencil cleaning is crucial in SMTThe Importance of Stencil Cleaning

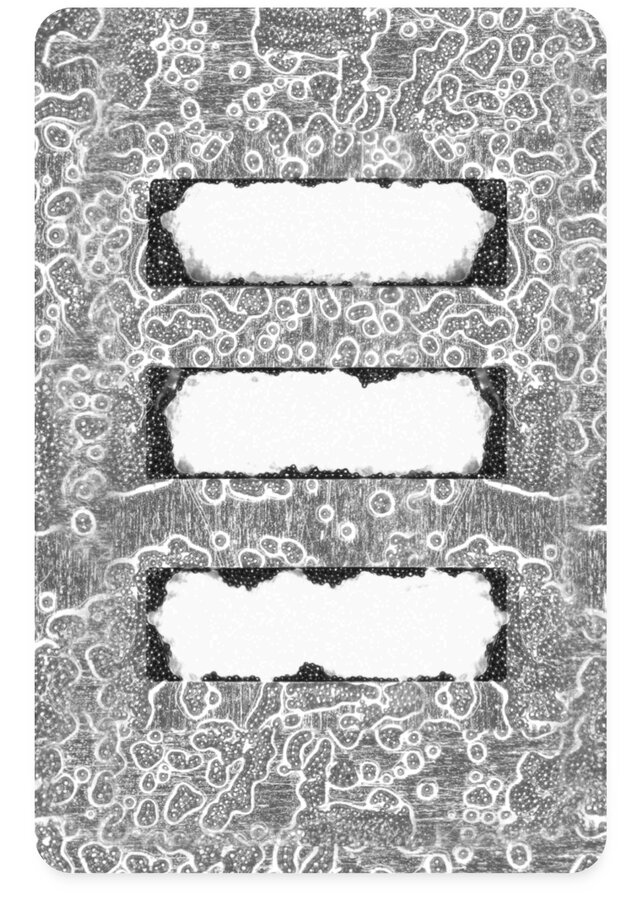

When manufacturing electronic assemblies, solder pastes, SMT adhesives or thick film pastes are printed or applied using stencils, pump print stencils or screens. Paste residues and remaining SMT adhesives on stencil surfaces and apertures can lead to misprints resulting in bridging and solder balling issues.

Stencil cleaning is crucial in surface mount technology as it ensures accurate solder paste application, improves solder joint quality, reduces scrap and rework, prolongs stencil life, and ensures compliance with industry standards. For optimum print results, it is necessary to clean the stencils and screens is an automated stencil cleaning machine or manually. Misprint cleaning and underside wiping in printers are also key aspects of ensuring reliability of your process.

Automated stencil cleaning is the preferred method to ensure that the cleaning results are always reproducible as compared with a manual cleaning process. Manual cleaning can cause mechanical damage and soften the stencil epoxy over time resulting in possible delamination issues.

IPC standard (IPC 7526), recommends the use of an automated cleaning system in order to meet all production requirements.

There are numerous processes available for stencil cleaning including spray and ultrasonic dip tank processes. Depending on the type, these can be used with solvent and aqueous-based cleaners. These cleaning machines can be further differentiated by the number of chambers that are available for the various process steps such as cleaning, rinsing and drying. This enables the cleaning process to take place in one or more chambers. Steel stencils, fine pitch and nano-coated stencils as well as screens are commonly cleaned in these machines.

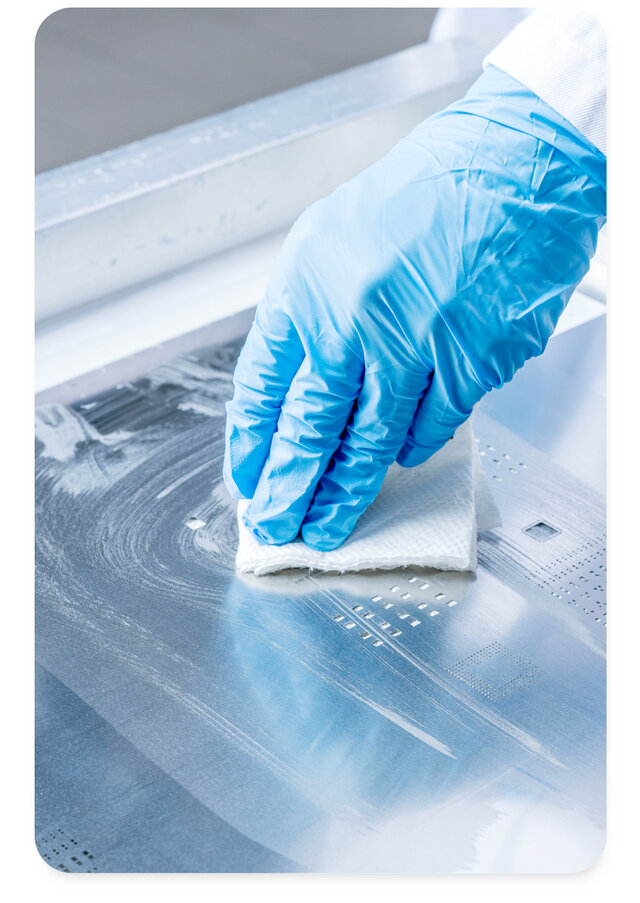

When cleaning a low volume of stencils, SMT adhesives and solder paste can be removed manually. Automated stencil cleaning is desirable with a large volume of stencils and has the added benefit of offering high quality repeatable results.

When cleaning manually, it is important to use a stencil wipe material that does not leave any lint or other residues on the stencil. At the same time, manual cleaning must be done carefully as too much force can easily damage the stencil.

Even though cleaning stencils can substantially improve the print results, misprints can still occur during the production process. When cleaning misprints, you are primarily removing solder paste that was inaccurately applied during the printing process.

When cleaning double-sided misprints, not only are misprinted solder pastes removed but also flux residues from the soldered side as well. Activator residues remaining on the board due to an inadequate cleaning process can cause improper assembly and field failures.

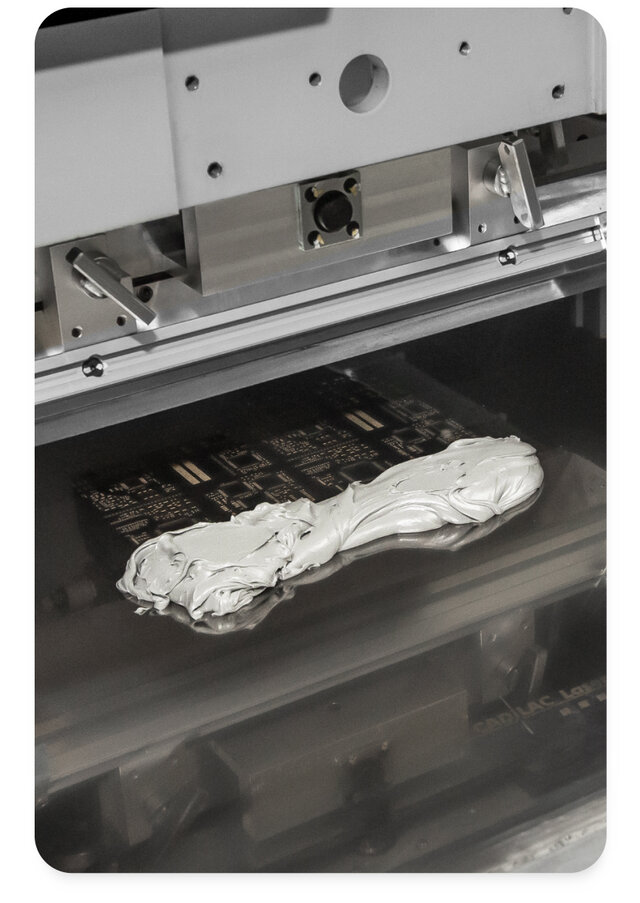

the stencil underside wipe process in SMT printers is critical in order to achieve reliable and consistent print results.

Using the right cleaning agent is most critical step in the underside wipe process. It must provide excellent cleaning results, and be highly compatible with the solder paste. During the underside wipe process, the flow of cleaning agent through the apertures and its interaction with the solder paste cannot be prevented. An incompatible cleaner, such as IPA (Isopropyl alcohol), can affect the viscosity of the solder paste and therefore impact the print result, i.e. the solder paste deposit. Additionally, the consumption of IPA is typically high due to evaporative losses (low flash point).

ZESTRON cleaning agents have been specifically designed for underside wipe processes. They provide excellent cleaning results, feature low consumption and do not affect the viscosity of the solder paste. ZESTRON offers aqueous-based as well as solvent based underside wipe cleaning agents for all stencil types including nano-coated stencils. These products have been approved by leading SMT printer and stencil manufacturers.

Step Inside our Technical Center

Our Technical Center in Manassas, VA, has a large selection of stencil cleaning equipment from multiple manufacturers, varying in size and price, and available for you to test.

searching for a product?Use Our Product Finder Tool

ZESTRON is committed to providing the highest quality cleaning products that deliver exceptional results every time. Our cutting-edge technologies and expertly formulated agents ensure unparalleled cleaning performance and reliability, making us the preferred choice of industry leaders worldwide.

Standards & safetyQuality, Efficiency & Environmental Friendliness: Stencil Cleaning at Zollner Elektronik AG

"Evaluating the CL500 and the water-based cleaning agent of the VIGON SC series was well worth the effort as the improved system provided Zollner with a return on investment within a short time."