ZESTRON® COATING LAYER TEST

Chemical test for localized detection of protective coating layer defects on electronic assemblies

Your Benefits ZESTRON® COATING LAYER TEST

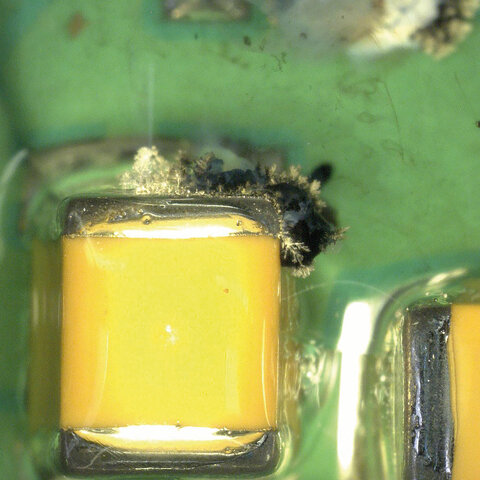

The reliability of protective PCB assembly coatings, with regard to climate and harmful gas safety, is essentially determined by the uniform application of the coating without interferences or gaps in the protective layer. In particular, common trouble areas such as solder joint edges and pore channels in coating pooling areas, when lacking a proper coating layer, have detrimental effects on the final board assembly. The ZESTRON® Coating Layer Test utilizes a black color reaction as a visual indicator of defects in the protective coating, even in the case of μ-coatings, adding standardized methods for coating thickness measurements with a rapid detection of defects in closed or dense coatings.

-

Supplementation of standardized methods for coating thickness measurement

The test is used for rapid detection of closed and dense coatings (solvent-based coatings, µ-coatings, parylene) on tin, copper, nickel & nickel-containing compounds as well as other base metals and alloys. -

Quick, easy and cost-effective

The test enables rapid detection of defects within a few minutes and can thus also be used during production for low-cost samples -

Accurate results even with thin layers

More precise than inspection with black light/ UV light, so that defects can be reliably detected even in thin layers -

Validation specifications from automotive OEMs

Part of the validation specification of various OEMs. -

Shows coating defect and missing edge covering

Thereby avoids expensive cutting in the event of edge covering problems. -

Additional use as solderability test

The indicator liquid can also be used as a quick test for checking the solderability of components, especially for THT components.

Product features

Surface Analysis

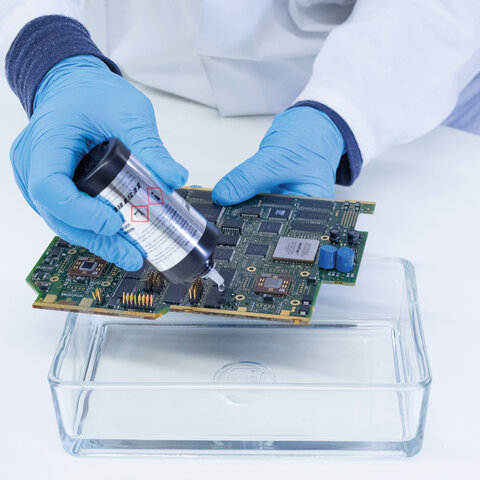

Simple Test procedure in a few steps

01

Apply indicator liquid

02

Wait three minutes, evaluate Black colouring = defect

03

Dab off test liquid