Great Performance!

Why cleaning power electronics pays off in the long run?

The saying "If you don't fight, you can't win" holds true not only in sports but also draws parallels to the cleaning of power electronics substrates. Just as in sports, if you neglect the cleaning process, you cannot expect to achieve optimised test results or improved conditions for subsequent manufacturing steps.

Emphasizing the importance of cleaning, this analogy highlights the necessity of proactive cleaning measures to ensure desired outcomes and enhance the overall quality of the production process.

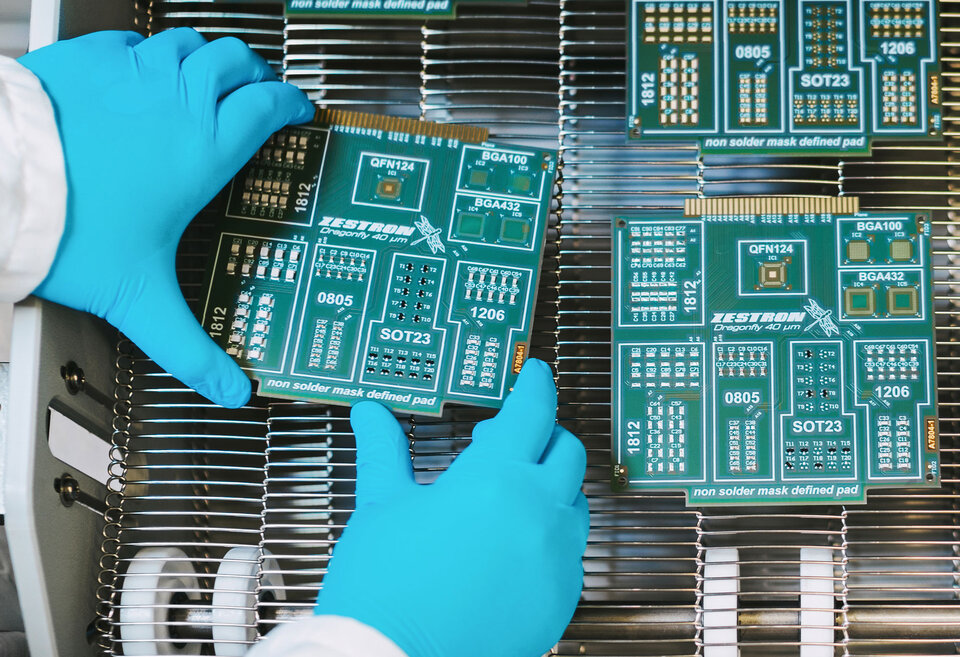

POWER ELECTRONICSCleaning of Power Modules

Thorough cleaning of Insulated Gate Bipolar Transistor (IGBT) modules in power electronics, as well as Direct Copper Bonded (DCB) substrates, is an essential requirement. Firstly, after die attachment, cleaning is necessary to prepare the substrate surfaces of the modules for wire bonding. Secondly, after soldering the substrates onto the heat sink, known as "heat sink soldering," cleaning is crucial to guarantee reliable thermal conductivity and long-term performance.

By prioritizing the cleaning of IGBT modules and DCBs at these stages, manufacturers can ensure the integrity and functionality of these critical components in power electronics applications.

cleaning processMain Requirements for Cleaning Process

To achieve enhanced results in shear tests, power cycling qualification, and increase production yield, two primary requirements must be met:

a) Complete removal of flux residues, particularly flux splashes, from the substrates.

b) Thorough and optical removal of stains or oxide layers from the surfaces of the substrate and chips.

ZESTRON addresses these requirements by employing specially developed processes that utilize aqueous cleaning media. These processes effectively generate high-purity surfaces, leading to a significant improvement in wire bond quality.

By utilizing ZESTRON's expertise and advanced cleaning techniques, manufacturers can ensure the removal of flux residues and other contaminants, resulting in improved performance, higher production yield, and enhanced reliability in shear tests and power cycling qualification.

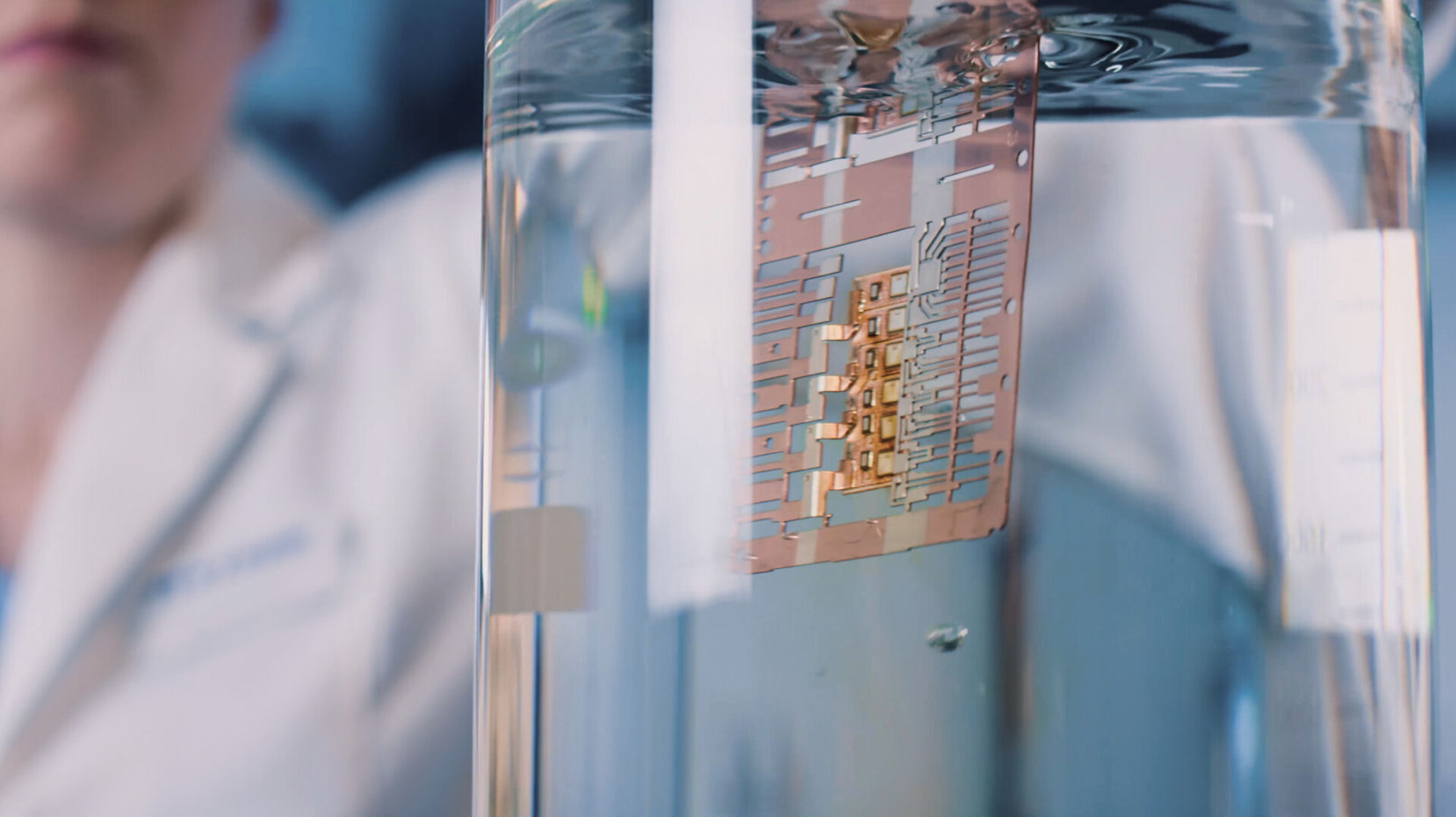

leadframes Cleaning of Leadframe-based Discrete Devices

In the die-attach process, MOSFETs, IGBTs, and SOTs are soldered onto the base substrate or leadframe using solder paste. This process involves high peak temperatures, which impose specific requirements on the cleaning process:

Due to the occurrence of high peak temperatures during the soldering process, the associated demands on the cleaning process also increase:

- Complete removal of the flux from the soldering process

- Removal of all inorganic stains and activation of the (copper) surfaces

- Material compatibility of the cleaner with all materials

Power-LEDs Cleaning of Power LEDs

ZESTRON excels in providing excellent cleaning performance for both substrate and chip surfaces of Power LEDs, utilizing water- and solvent-based cleaning media. This ensures enhanced bond quality, improved results in tensile and shear tests, and optimal adhesion of the molding.

In power LED production, it is critical to perform cleaning after the die attach process. Failure to remove flux residues would lead to unfavourable conditions during wire bonding, potentially resulting in bond fractures or chip defects.

A cleaning process adapted to power LEDs with water-based cleaners or modern solvents from ZESTRON can provide a remedy. This guarantees optimal surface cleanliness for thin-wire bonding as well as an increased yield.

ZESTRON offers a specialized cleaning process tailored to power LEDs, utilizing water-based cleaners or modern solvents. This customized approach guarantees optimal surface cleanliness for thin-wire bonding and enhances overall yield.

More short storiesThis might also interest you:

CLEANING OF POWER ELECTRONICSFind your suitable product now.

ZESTRON offers both water- and solvent-based products that guarantee reliability in your cleaning process.