Advancement of pH Neutral Cleaning Agent

The next-generation pH-neutral cleaning agents offer a safe, efficient and compatible cleaning solution for electronic assemblies.

CLEANING AGENTCleaning Performance with pH-Neutral Cleaning Agent

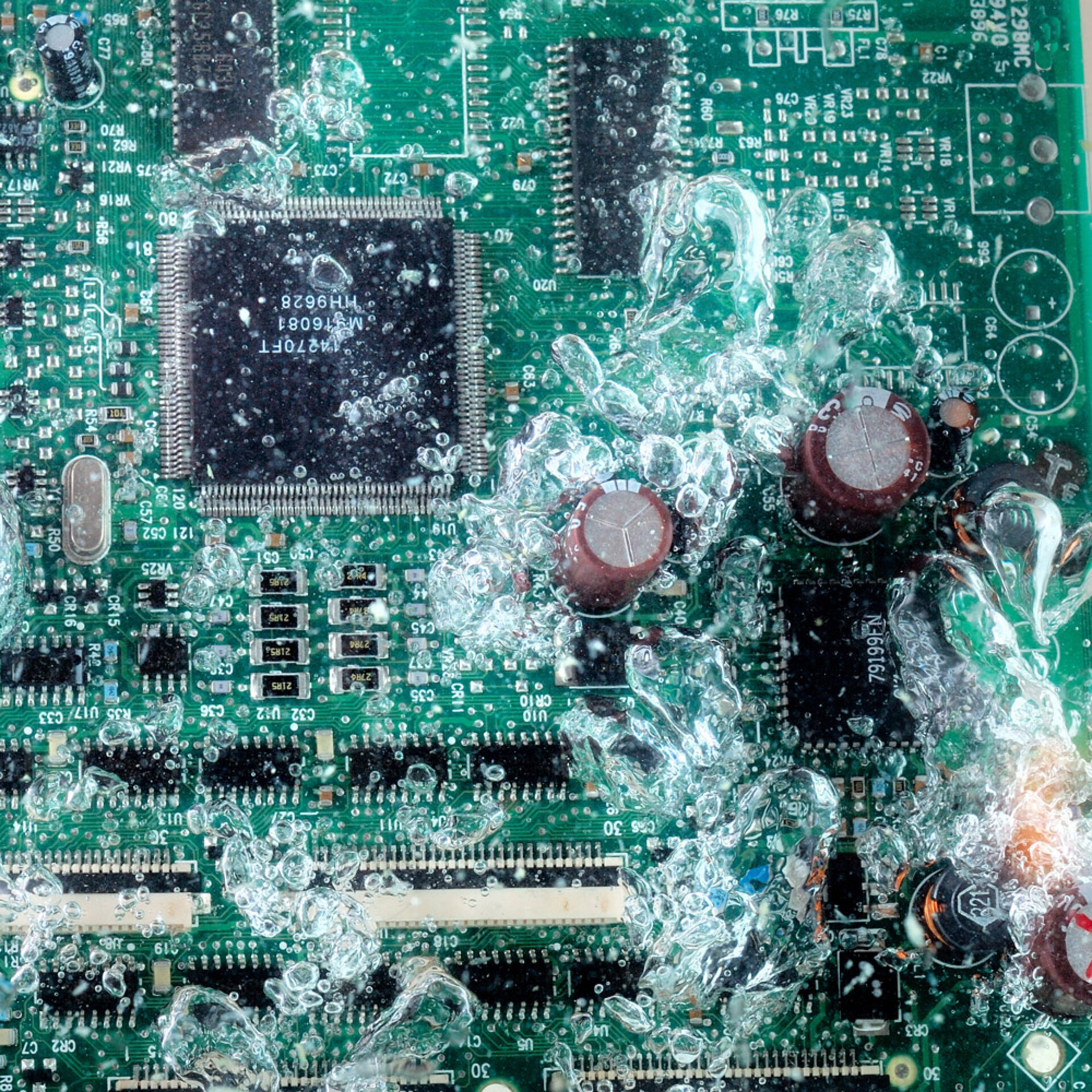

With electronic assemblies advancing in conditions like miniaturisation, larger component packages, higher lead counts, reduced conductor spacing, tighter pitch and lower standoffs, effective cleaning has been greatly challenged. Different types of effective modern cleaning agents are being developed to overcome these challenges.

Modern aqueous-based cleaning agents can be alkaline or pH neutral, and engineers make the choices depending on the degree of solvency required to clean the assemblies. While selecting the most effective cleaning agents that synergise with the thermal and mechanical energies for the cleaning process, companies are also looking into environmental factors such as the environmentally friendly pH values, biodegradable, Hazardous Air Pollutants (HAPs) measures and much more.

cleaning performance Why pH-Neutral Cleaning Agent?

Zestron’s pH-neutral cleaning agents have been specifically developed with J-Std-001H cleanliness qualification standards that are based on Surface Insulation Resistance (SIR) and Ion Chromatography (IC).

Cleaning agents with a pH-neutral formulation have become the new standard for environmentally friendly solutions as they offer a range of benefits, apart from their main feature, which is to effectively remove flux residues and other contaminants for reliability and performance.

Benefits of pH-Neutral Cleaning Agent

In a pH-neutral environment, the formulations potentially eliminate the need for wastewater neutralisation treatment during the process due to their initial pH value. For companies aligned to environmental impact initiatives such as ISO 14000 compliance, the pH-neutral cleaning agent meets the Environmental Health and Safety (EHS) requirements.

In addition, the pH-neutral cleaning agent has great adaptability to changes in flux chemistry formulation while maintaining their cleaning efficacy. They carry a high compatibility with a wide range of materials, which addresses the challenge related to sensitive components and surface finishes.

Its neutral pH also enables the use of a wide range of inhibitors, as low amounts of inhibitors are required. Importantly, they leave no alkaline constituents inside the packages, as any chemical residues left within the package may lead to corrosion issues.

In short, pH-neutral cleaning agents can meet stringent cleaning requirements and provide excellent cleaning results on the surface and underneath the components, while exhibiting excellent material compatibility with lower wash concentrations.

- Provides excellent cleaning results

(*may vary based on the types of contaminants) - Able to penetrate the tiny spaces in and around components

- Eliminates wastewater neutralisation treatment

(+ Minimizing operation costs) - Easily rinsed and dried

- Excellent material compatibility

- Lower wash concentration

- Reduced the usage amount of inhibitors

*The information from this short insight is referenced from the article “Revolutionizing PCB Assembly Cleaning: The Next Generation of pH-Neutral Defluxing Agents”, “pH-Neutral Cleaning Agents: Technology and Performance”, “Compatibility of pH-Neutral Cleaning Agent with Under-bump Materials” by ZESTRON America & Malaysia Team

get more insightsExplore Whitepaper Collections.

Check out our technical studies related to pH-Neutral Cleaning Agents case studies.

Compatibility of pH-Neutral Cleaning Agent with Under-bump Materials

Revolutionizing PCB Assembly Cleaning: The Next Generation of pH-Neutral Defluxing Agents