Insulation Coordination in E-Mobility:

Minimizing Failure in High-Voltage Systems

As electric vehicles evolve, so do the demands on high-voltage system design. Insulation coordination is becoming a key reliability factor—especially as voltage levels rise beyond 800 V. Traditional approaches are reaching their limits. This makes it essential to rethink how risks are managed in high-voltage environments.

Insulation coordinationNew Challenges Require Innovative Solutions

The transition to high-performance electric mobility systems is redefining the design requirements for power electronics. Voltages in the range of 400–500 V—and increasingly up to 1200 V—demand a reevaluation of insulation strategies. Insights from low-voltage applications, especially below 60 V, no longer apply when it comes to material behavior, contamination, and dielectric strength.

In this context, maintaining safe distances between conductive elements remains a fundamental principle. However, determining those distances relies heavily on the pollution degree, which characterizes the type and conductivity of contamination as well as how frequently surfaces are exposed during operation. Defining this parameter with confidence now requires more than theoretical models—it calls for evidence-based analysis adapted to high-voltage conditions.

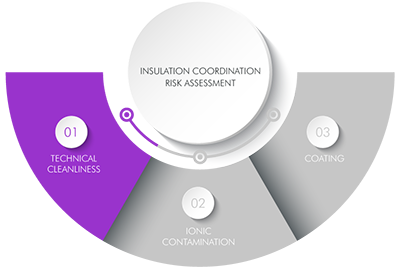

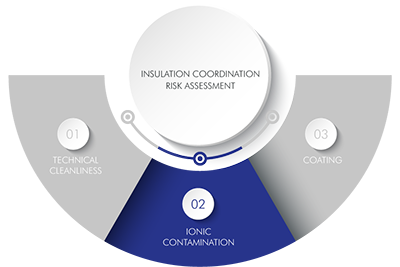

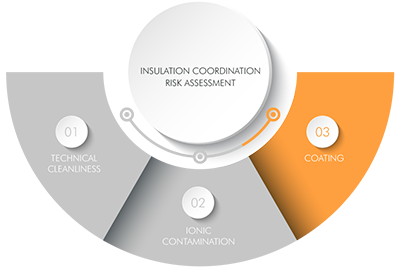

insulation coordinationRisk Assessment as the Key

Meet OEM requirements and avoid failures of power electronics in the automotive sector. Utilize our expertise in the analysis and risk assessment of particles, ionic contaminants, and insulation materials. We assist you in conducting a comprehensive risk assessment to successfully address these challenges.

Learn more about the three pillars for optimizing the pollution degree and the reliability of your power electronics.

01 | TECHNIcal cleanlinessUnderstanding Risks Rather Than Just Counting Particles

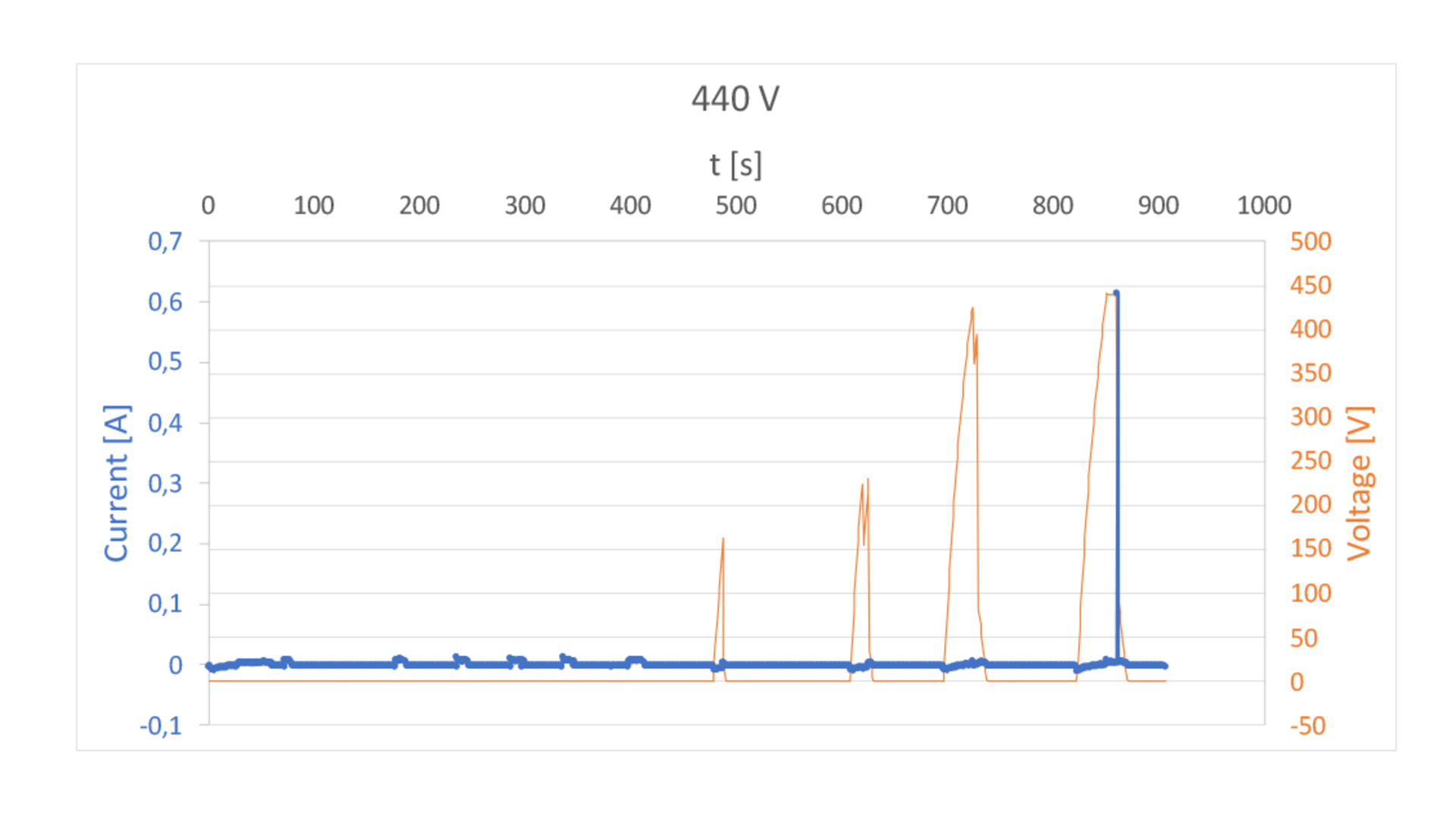

Because merely counting particles often does not provide insights into the risk, at ZESTRON, we rely on innovative breakdown voltage analysis to determine the failure risk, rather than solely relying on the particle count. Through breakdown voltage measurement, we can test the voltage resistance of particles up to 800 volts. Additionally, we analyze their material composition, allowing us to assess the electrical behavior of particles.

your benefits

-

Complete Solution

With us, you receive not only measurement results but also tailored recommendations on how to avoid critical particles. All in one place! -

Analyses at Early Stage

We can provide meaningful results even before production starts. Just 2-3 representative assemblies manufactured on an existing production line are sufficient. This saves costs and enables optimal preparation. -

Time Savings

Our analysis results and recommendations are delivered within the agreed-upon timeframe. You no longer need to wait for statistically significant data from particle trap analysis. -

Pollution Degree Selection

Through our analysis, you gain valuable insights into particle behavior, providing a solid basis for selecting the appropriate pollution degree for your requirements.

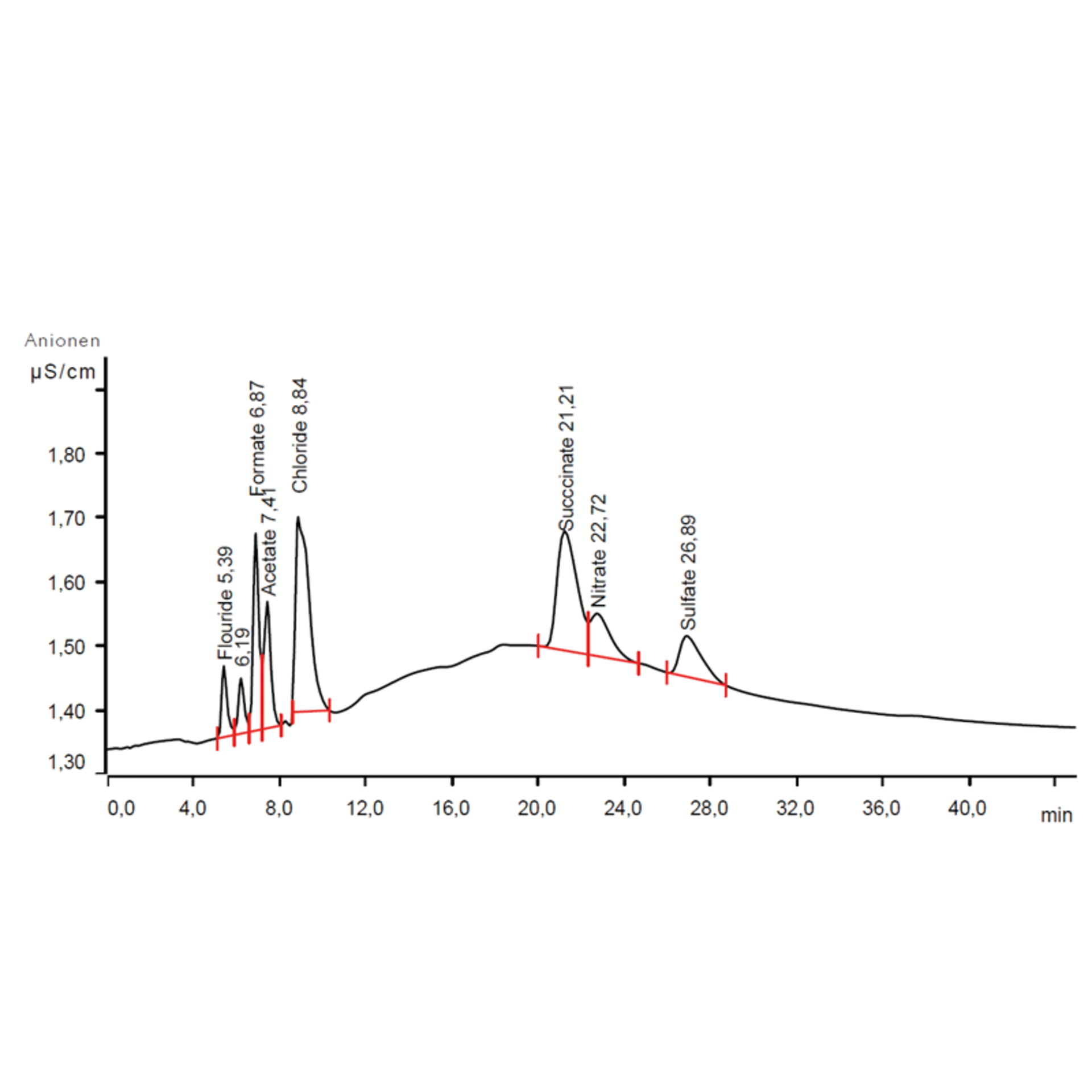

02 | Ionic contaminationTracking Leakage Current

Ionic contaminations can lead to leakage currents, especially in combination with moisture. To assess the effects of these contaminations on leakage current formation and dew formation, we use the method of ion chromatography. This method allows us to precisely determine the type and quantity of ionic contaminants.

Your benefits

-

Comprehensive Analyses

By detecting ions, we can identify potential failure mechanisms. -

Concrete Recommendations

We not only assist with the analysis but also offer specific recommendations for improvement and problem resolution. -

Efficient Resource Utilization

Our tests require only 2-3 assemblies to achieve meaningful results. -

Precise Test Results

The results of our tests provide valuable insights into how well the coating protects against harmful environmental influences and whether it can meet the requirements of insulation coordination according to IEC 60664.

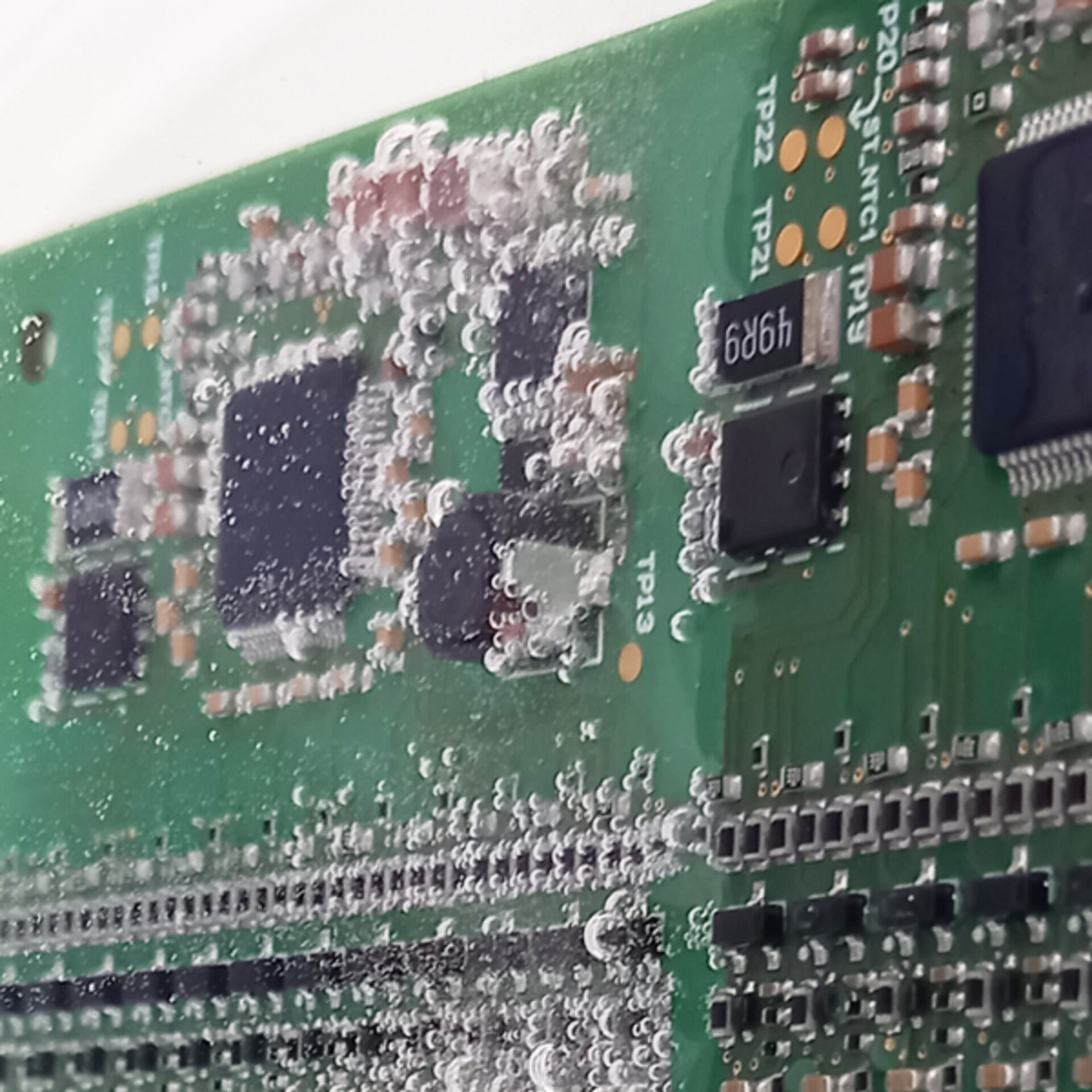

03 | coatingReliable Protection Against Moisture

Our evaluation ensures the protective effect of coatings by ensuring they are free from bubbles, pores, or cracks. Reliable coating is crucial to effectively protect assemblies and components from harmful environmental influences like moisture. Our tests detect defects, edge defects, and assess effectiveness against corrosive gases and moisture.

your benefit

-

Quick Results

Our coating tests provide reliable results within hours compared to traditional, time-consuming gas exposure tests that can take days. -

Remedial Measures

We offer concrete suggestions to avoid coating defects and enhance reliability. -

Informative Test Results

The results of our tests provide valuable insights into how well the coating protects against harmful environmental influences and whether it can meet the requirements of insulation coordination according to IEC 60664.

our zestron promiseYour Competent Partner in the High-Voltage Field

- Comprehensive analysis, data interpretation, and recommendations - all in one place

- Receipt of robust results in the form of a written report, suitable for submission to the OEM

- Expert team with years of experience in critical areas of Technical Cleanliness, Ionic Contaminants, and Coating for high-voltage and insulation coordination applications

- No-obligation initial consultation and transparent quotation

Contact us for a no-obligation initial consultation and receive tailored solutions for your high-voltage requirements.

Reliability is no accident

Our experts analyze and assess the risk of failure due to contamination (particles/ions) and verify the reliability of protective coatings. Together, we develop solutions for you and support you in selecting the pollution degree according to DIN EN 60664-1.

insulation coordinationTechnologie Coaching Packages

Or book a tailored technology coaching package now, focusing on the three pillars of risk assessment and insulation coordination, and maximize the reliability of your power electronics.