Avoid Failures Before They Occur

Tailor-Made. Reliable. Experienced. - ZESTRON Reliability & Surfaces

AVOID FIELD FAILURESTechnology Coaching

Ionic or particulate contamination on the surface can cause electronic assemblies to malfunction. To minimise the risk of failure and ensure reliability, our experienced Reliability & Surfaces Team (R&S) offers customised technology coaching.

Electrochemical migration, leakage current or a short circuit are typical failure mechanisms. Within the scope of technology coaching, our R&S team advises and supports you on how to avoid failures and produce reliable, moisture-resistant assemblies - along the entire value chain.

YOUR ADVANTAGESAvoid Failures and Produce Reliable Assemblies

1. Preventive assessment of the risk of default before production starts

2. Analysis of failures during validation tests

3. Cause analysis in case of damage in the field

SOLUTION-ORIENTEDDriven by Reliability

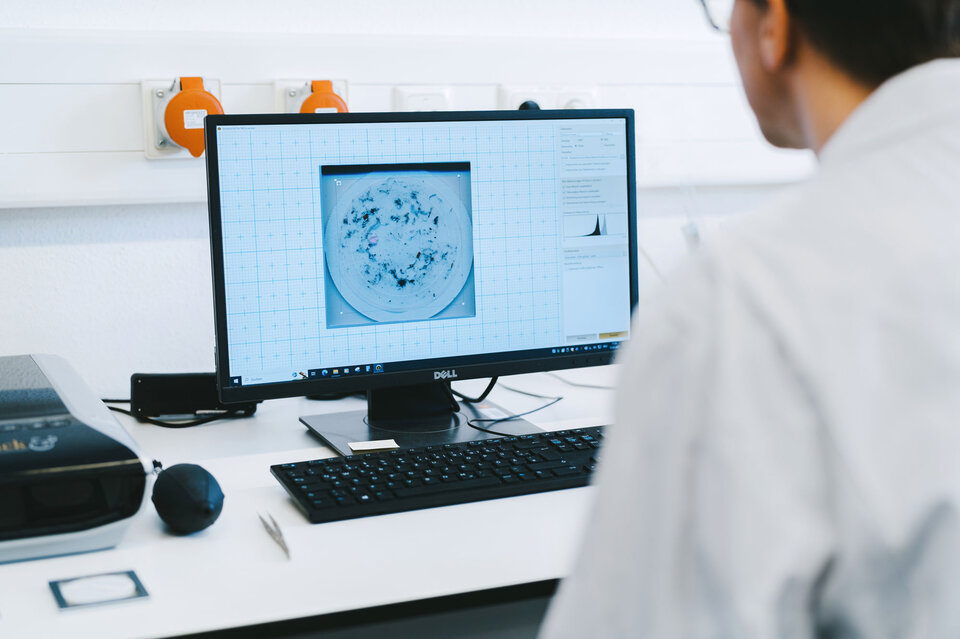

On the way to solving your challenge, the first step is to identify the (potential) failure mechanism. To do this, we use a wide range of analytical methods such as SEM/EDX, ion chromatography or fracture stress analysis. We put the results into the overall context of your problem and then work out feasible measures to solve it.

Technology coachingReliability is No Coincidence - Benefit From our Technology Coaching

Everything From a Single Source

Analysis, interpretation and remedial action

Tailor-Made

Analyses and solutions tailored to your challenge

Discretion

Signing of an NDA on request

Speed

Max. 5 weeks processing time from placing of order and receipt of the objects of investigation

Many Years of Success

Continuously updated in research projects and studies

TECHNOLOGY COACHING PACKAGESEmpowering Solutions: Explore Our Specialized Technology Coaching

Every challenge is individual. But our experience shows that some problems occur more frequently than others. In order to be able to help you even faster and in a more targeted manner, we have therefore put together packages with the appropriate analyses.