Field Failures in Power Modules: Identifying Root Causes and Developing Effective Solutions

You are experiencing failures of Power Modules in your systems, either in the field or during testing, and need to understand the root causes quickly and eliminate them sustainably? Using proven analytical methods, we work with you to pinpoint the failure mechanisms within just a few weeks and derive transparent, practical, and reliable solutions.

Failure remediation Power modulesUnderstanding Failures, Finding Solutions

Our experts support you in analyzing and isolating damage patterns such as

-

sudden field failures,

-

unexplained increases in leakage current,

-

dendritic growth,

-

insufficient humidity robustness, or

-

thermally induced damage.

Together with you, we develop solutions that are transparent, traceable, and economically sustainable in the long term.

Get in touch with us. You can rely on our confidential and focused support in accordance with ISO/IEC 27001 and TISAX.

your partner at your sideOur Approach

-

Precise failure analysis on the power module: You share your specific application with us, including all relevant boundary conditions such as installation layout or operating environment. We analyze the failure patterns in detail, considering surface, geometry, and encapsulation materials, and develop well-founded hypotheses about the root causes. This provides you with a solid technical basis for targeted next steps.

-

Collaborative root cause evaluation: We review the results directly with your team and, if required, also together with your module supplier. This transparent, collaborative exchange enables you to make informed decisions and ensures that all stakeholders have a common understanding of the causes and possible solutions.

-

Solution-Focused Implementation: Based on the analyses and discussions, we define suitable corrective measures together with you. Our goal is to implement solutions that reliably prevent future failures, strengthen the reliability of your systems, and remain both technically and economically viable.

from practiceReliable Support in the Event of Demage

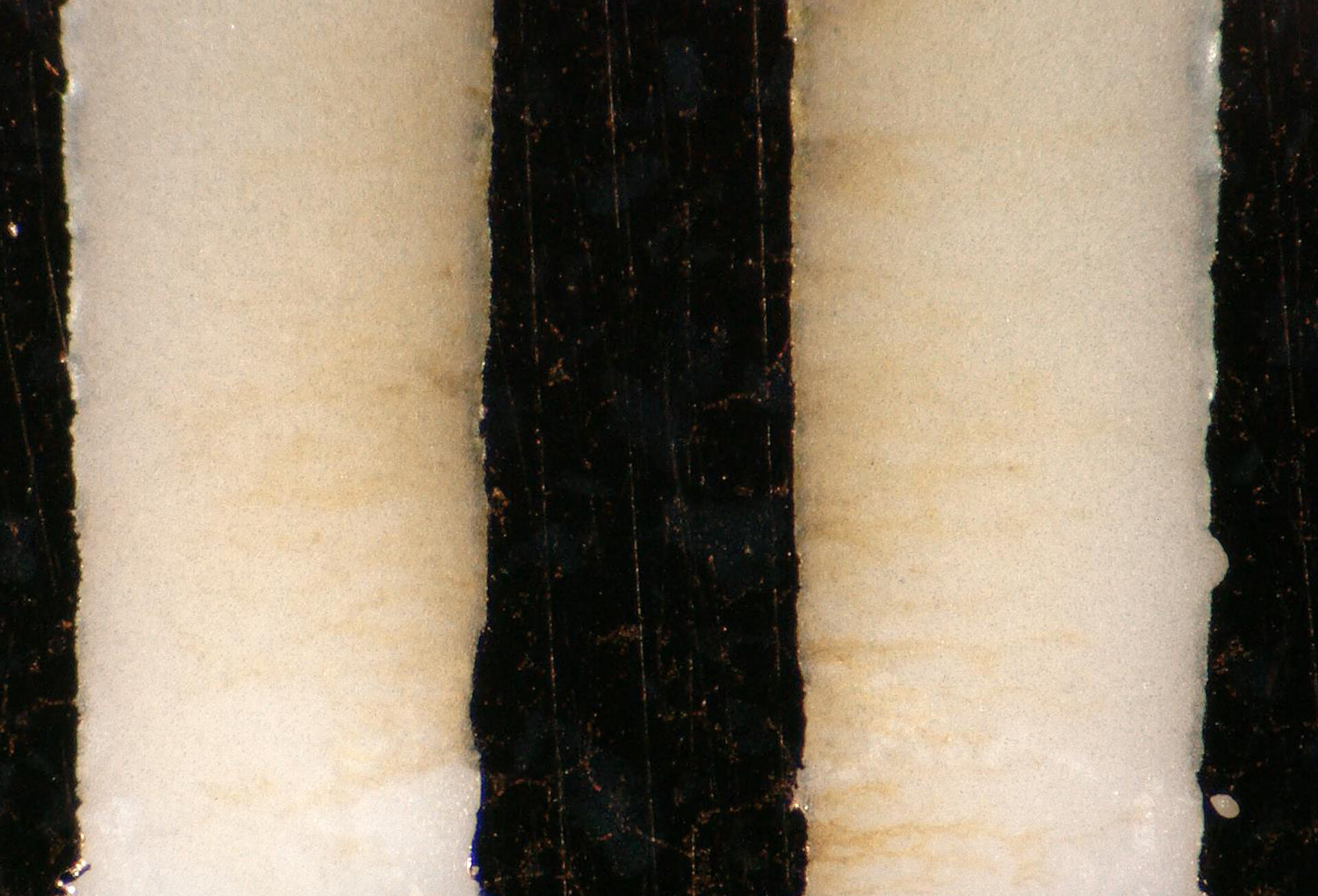

Whether dendrites, delamination, cracks, or corrosion, we analyze complex failure patterns in power modules, clearly identify the root causes, and derive effective corrective actions.

Below are two real-world examples that provide insight into our tailored approach.

Dendrites in Power Modules: The Silent Risk with Costly Consequences

Reliably Test Opaque-Encapsulated Power Modules

Acute Challenges or Failures in Power Modules?

We support you with fast and precise failure analysis and collaborate with you to develop sustainable solutions that address the root cause.