Solutions for Reliable SMT Electronics

Your partner for precision cleaning, detailed surface analytics, and optimization of downstream process steps for electronic assemblies.

SMT ElectronicsOur Holistic Approach

Whether it’s process development or the optimization of cleaning processes, we take a holistic view of your requirements – from selecting the right cleaning equipment and chemistry to process analytics and monitoring to ensure reliable assemblies.

Cleaning process qualification Custom Process Development & Optimization

Cleaning process qualification Custom Process Development & Optimization

ZESTRON works with you to develop a cleaning process perfectly tailored to your assembled PCBs. Whether you’re optimizing an existing process or developing a new, custom solution – we support you as a trusted partner from the very beginning.

Cleaning System Selection Cleaning Trials at Our Technical Center

Cleaning System Selection Cleaning Trials at Our Technical Center

We offer an independent comparison of equipment and processes from leading manufacturers for cleaning assembled PCBs. Under production-like conditions, we carry out cleaning trials to develop the optimal solution – tailored to your specific requirements and budget.

Cleaning agentsIf ZESTRON Can’t Clean It, It Can’t Be Cleaned

Cleaning agentsIf ZESTRON Can’t Clean It, It Can’t Be Cleaned

Our cleaning solutions are specifically designed to meet the high purity requirements of SMT production. With high-performance cleaning chemistry, we help you meet your individual quality standards.

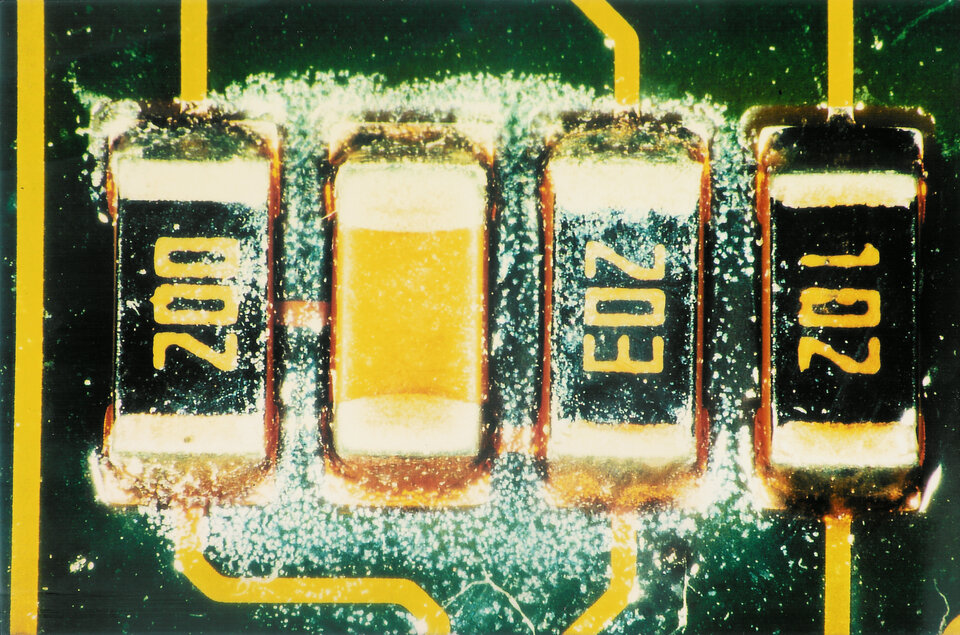

cleanliness analytics Surface Cleanliness Analysis

cleanliness analytics Surface Cleanliness Analysis

Using state-of-the-art analytical methods and in accordance with international standards such as IPC, MIL, or J-STD, we verify the surface cleanliness of your assembled PCBs in our in-house analytical center.

process controlCleaning Bath Monitoring

process controlCleaning Bath Monitoring

We monitor the quality of your cleaning bath to ensure consistent cleaning results and offer efficient methods for both manual and automated bath monitoring within your production environment.

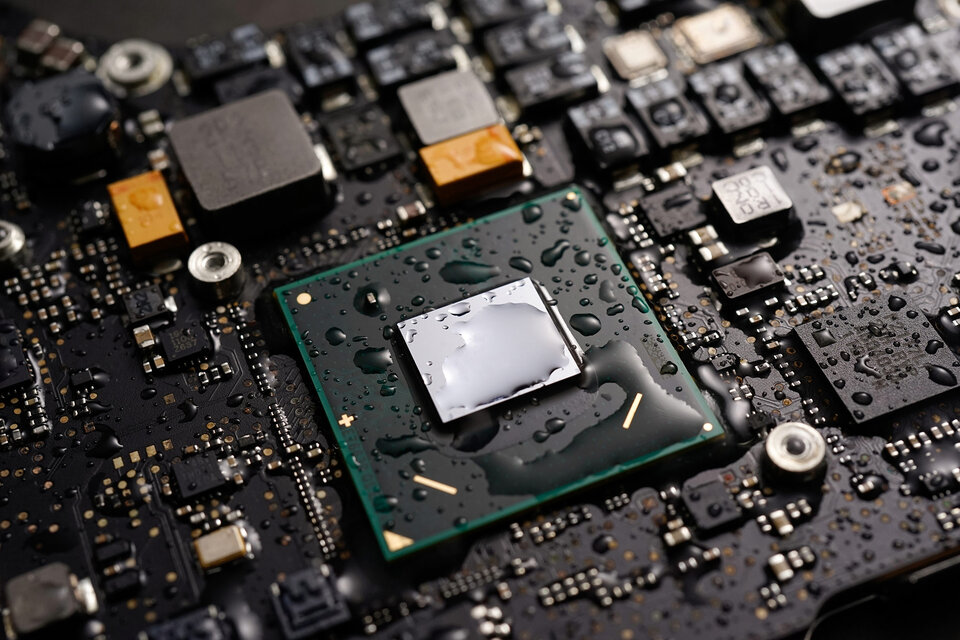

Failure Analysis & Risk Mitigation For Your Reliability and Dependable Product

We identify failure causes on the surface of your assemblies, uncover weak points, and develop customized solutions to ensure safe and reliable products.

your partner forTailored Solutions for Your Electronics Cleaning

From process qualification and the selection of suitable cleaning equipment

and media to quality control.