InsightsWhite Residues / Spots on Assemblies: What’s Behind Them?

Understanding White Residues on PCBs: Causes and Solutions from Origin to Resolution.

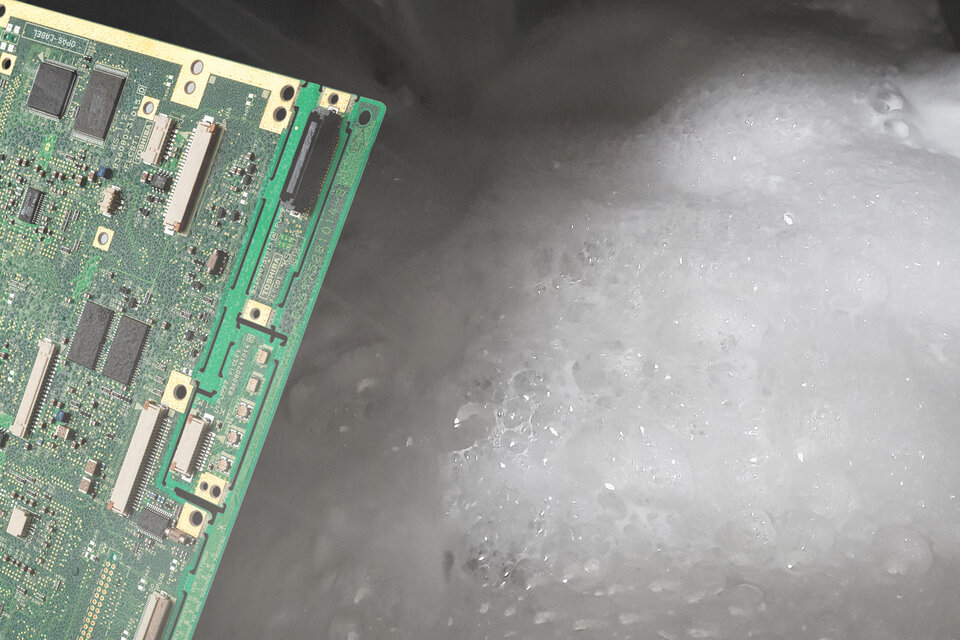

failure causesWhite Residues After Cleaning?

Anyone involved in cleaning electronic assemblies has likely encountered the phenomenon of so-called "white spots."

But what’s behind them? Why do these residues appear, and why are they white? What causes them, where do they come from — and most importantly: how can such spots be prevented?

WHITE residues?Multiple Causes, Pragmatic Solutions

When white residues suddenly appear on assemblies for unknown reasons, the customer is often confused - and the first idea is often the same: something must be wrong with the cleaner. However, this is only the cause in extremely rare cases. In the absolute majority of cases, there are other causes - but these can be manifold.

In many cases, changes in the assemblies are responsible. Cheaper materials, less development time or simply a change of supplier can be the cause. A supposedly more favorable offer can also have disadvantages. If the new parts are not compatible with the previous cleaning process, problems arise - not infrequently in the form of white residues. If it is not possible to switch back to the old components, the only option is often process optimization.

white spots on PCBAPossible Causes and Solutions

White residues on electronic assemblies pose a risk to process reliability and product quality. We explain how they form – and how they can be effectively prevented.

cause & solution approachPartially Cured Solder Mask

A commonly overlooked cause of white residues on electronic assemblies is a solder mask that has not fully cured. In this state, water from the cleaning process can penetrate the solder mask material and condense at room temperature, ultimately leading to the formation of white spots.

A potential solution is as pragmatic as it is simple: using a hot air blower held over the affected assembly for a short period can make the milky-white spots disappear quickly.

cause & solution approachSolder Paste Change

Switching solder pastes can also lead to white residues on the circuit board. If this change is made without consulting the cleaning agent manufacturer, the cleaner may not optimally remove the new solder paste under unchanged system settings. In such cases, adjusting the cleaning parameters in close coordination is essential to resolve the issue.

cause & solution approachInfluence of Rinse Water

Another possible reason for the formation of white residues lies in the quality or temperature of the rinsing medium.

These issues can be resolved by specifically adjusting process parameters or by treating the rinse medium. If the cleaning agent has already been used multiple times, increasing its concentration may help restore the desired cleaning performance.

you can count on usWe Find Tailored Solutions for Every Case

In most situations where white residues appear, targeted process optimizations lead to effective results. If this approach does not resolve the issue, our Application Engineering department is ready to analyze the case individually and identify the root cause together with you. A change of cleaning agent is rarely necessary.

whitepaper-collectionResidues on PCBs - Cuases and Remedial Measures

Surface contamination, such as white spots, streaks, or solder balls on electronic assemblies, can range from harmless to critical. In our whitepaper, we explore the causes and provide optimization suggestions.

more cleaning insightsThis Might Also Interest You:

OPEN QUESTIONS?Do You Have Individual Questions?

Our ZESTRON application technology is available to advise you on your problem.