PCB Cleaning Solutions - Rinsing Water: What Must Be Considered in Water Management and Quality Monitoring

Time for a Fact checkRinsing Water for PCBA Cleaning

On the Test Bench: Water Management and Quality Control

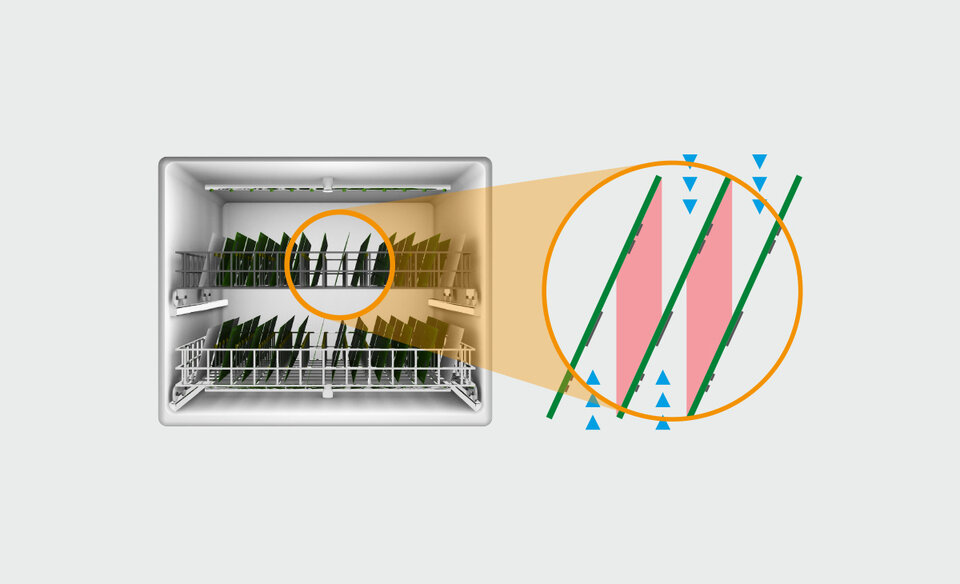

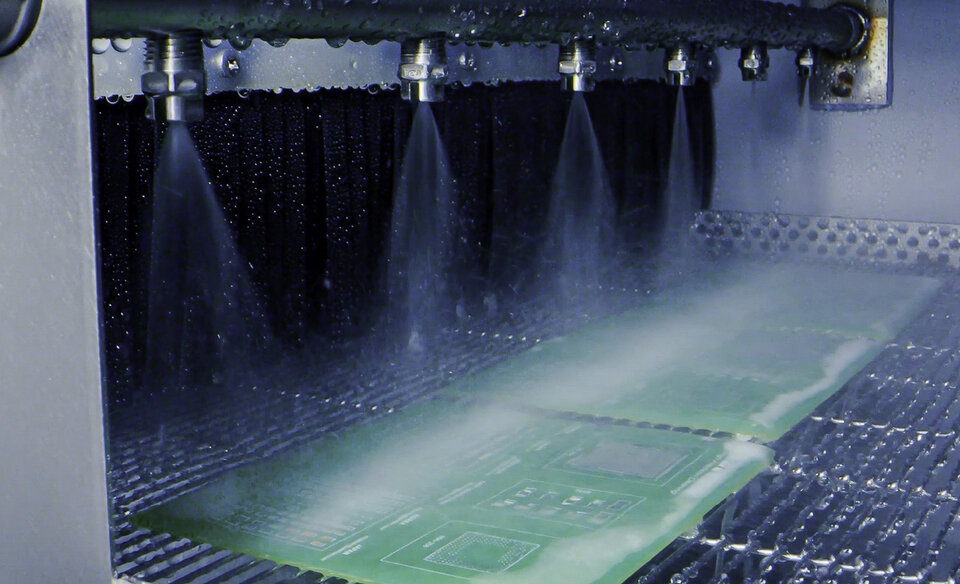

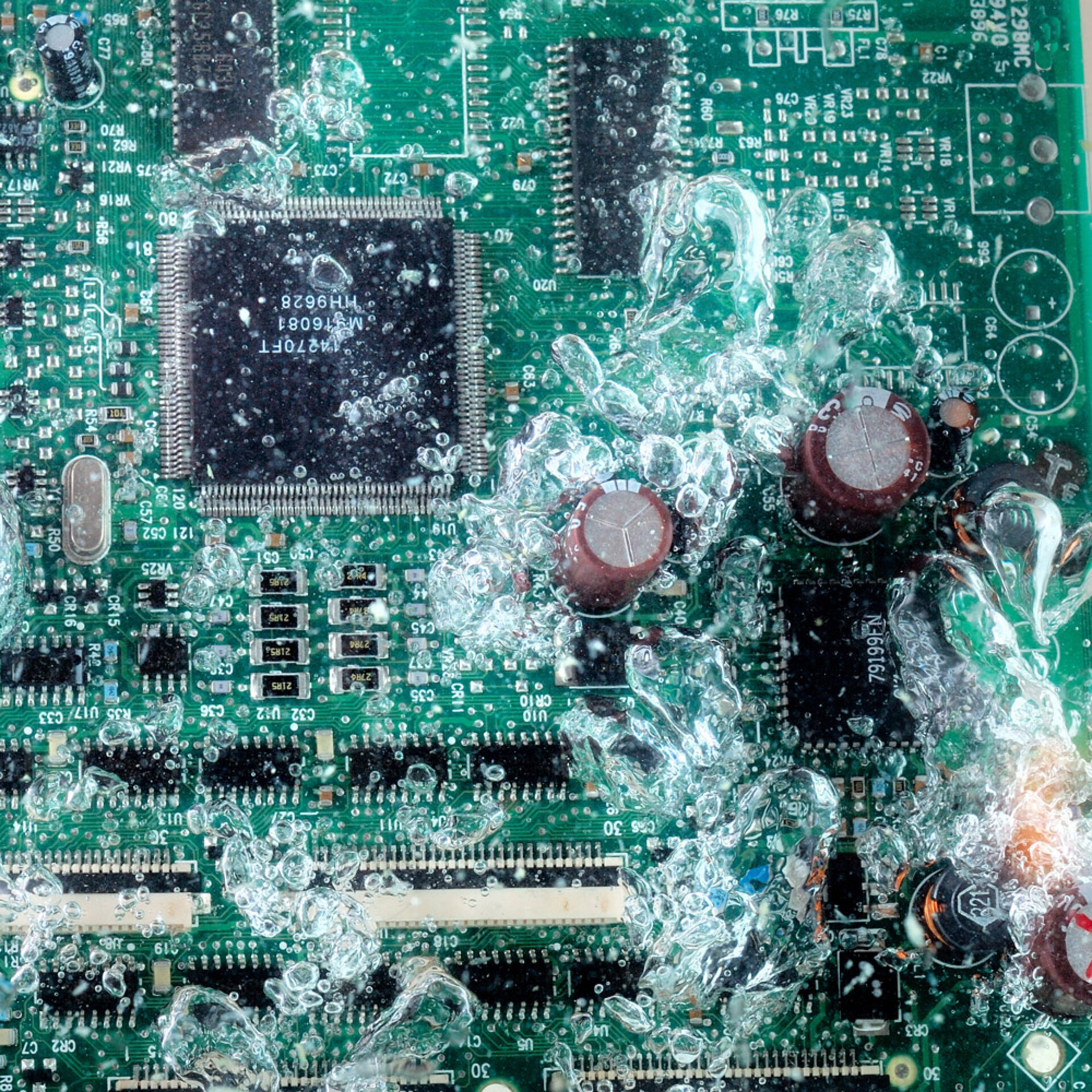

Removing flux and other production residues from the assembly surface has been proven to increase the error-free function of the assembly in the final product. A part of the cleaning process that should not be neglected is the rinsing stage. Here, the assemblies are freed from cleaning agent and contamination residues - comparable to rinsing in the dishwasher at home.

The quality of the rinse water is therefore crucial for a clean surface. But what is there to consider in water management and quality monitoring?

We have checked this question in our fact check. Among other things, you will learn how rinse levels can differ, what types of water cycle there are and how the quality of the rinse water can be monitored.

Now, Watch the Fact Check in the Video ▼

fact check to readRinsing Water Quality for Flux Removal

On the Test Bench: What Are the Water Cycle and Quality Monitoring Options?

Not All Rinse Waters Are the Same

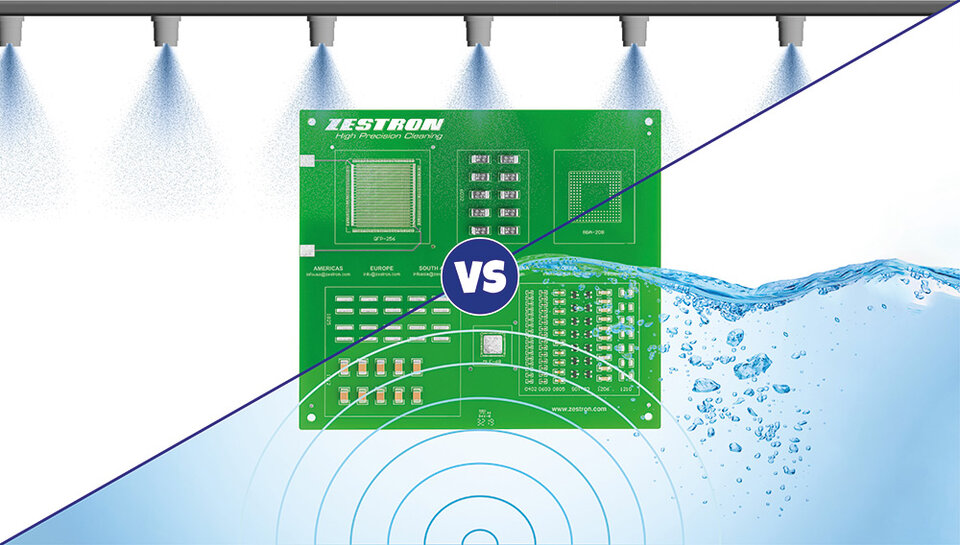

The cleaning process for PCBAs is similar to that for dishes in the dishwasher: cleaning - rinsing - drying. With the subtle but decisive difference in rinsing. The city water from the tap does not have the necessary quality to rinse all residues and impurities from the surface. Therefore, assemblies are rinsed with fully deionised water (DI-water).

Water Management: What Does It Involve?

Water Cycle

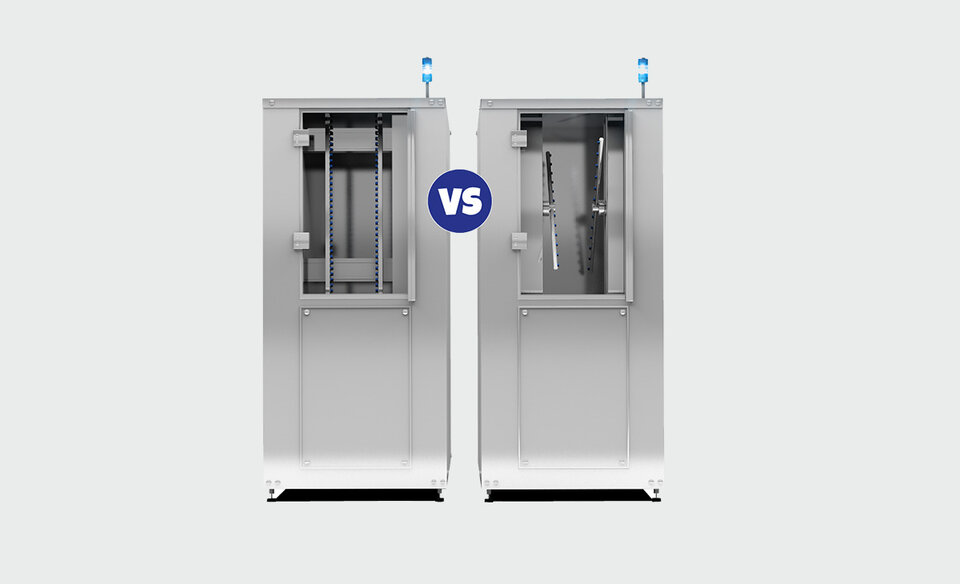

Just as there are different cleaning systems, there are also different options for the rinsing cycle. Depending on the system configuration, rinse water can also be treated and used several times. Which circuit is the most suitable depends on various factors, such as available budget or also legal framework conditions.

Quality Monitoring

In order to achieve an optimal cleaning result in the long term, the quality of the rinse water must be checked regularly. The correct method provides information as to whether the rinse water needs to be changed or can continue to be used. However, which is the right method for the quality check depends on the selected water circuit.

The Answers

The topic of rinse water offers plenty of room for questions. Our expert answers the most frequent ones in the fact check.

-

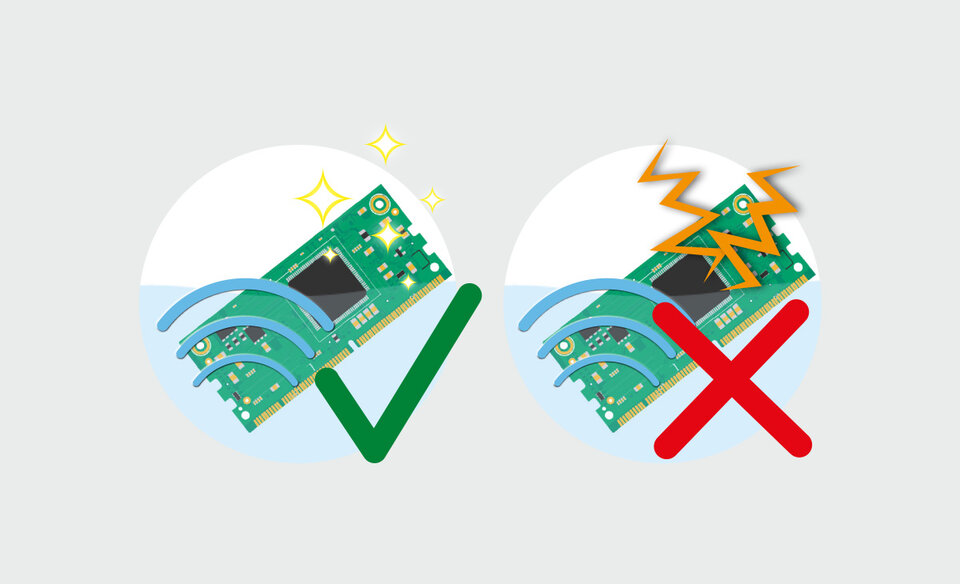

The consequences of inadequate rinsing or rinse water quality.

-

Ways to monitor water quality and when it is no longer sufficient

-

Which water cycles exist and when they make sense

-

Which framework conditions, such as permits, you should already pay attention to when selecting a system.