Which Immersion Processes Exist and How Suitable Are They for Cleaning Assemblies?

TIME FOR A Fact checkImmersion Cleaning for Electronic Assemblies

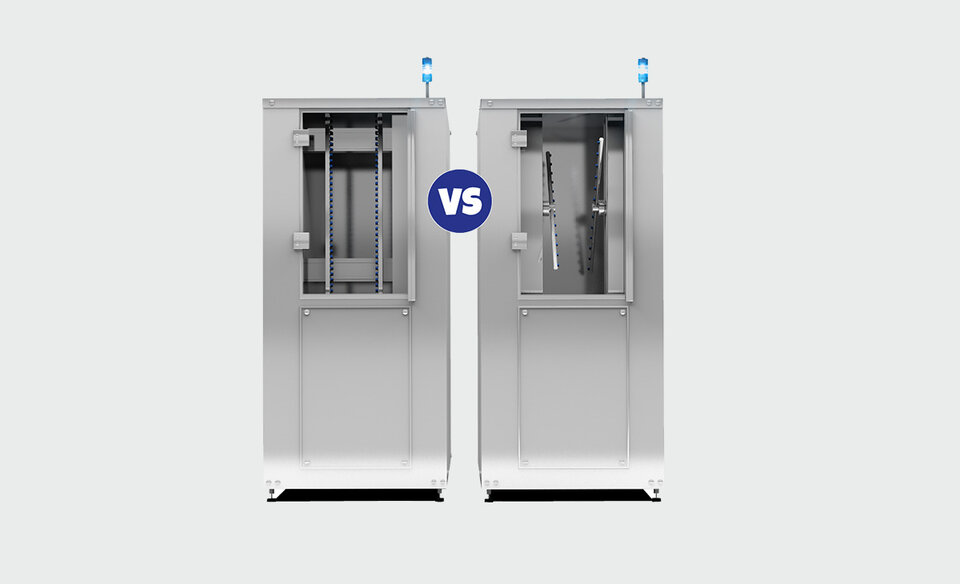

On the Test Bench: Which Immersion Processes Are Suitable?

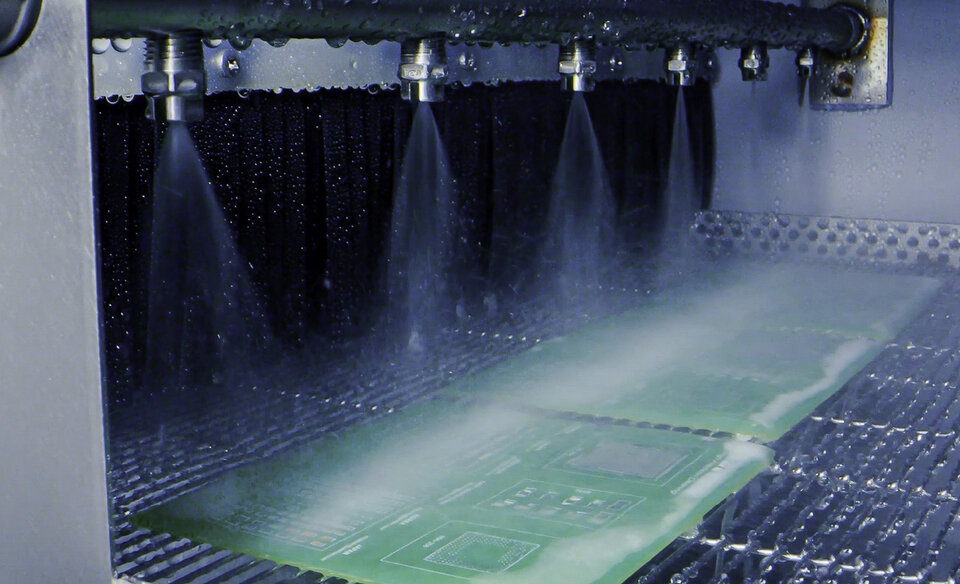

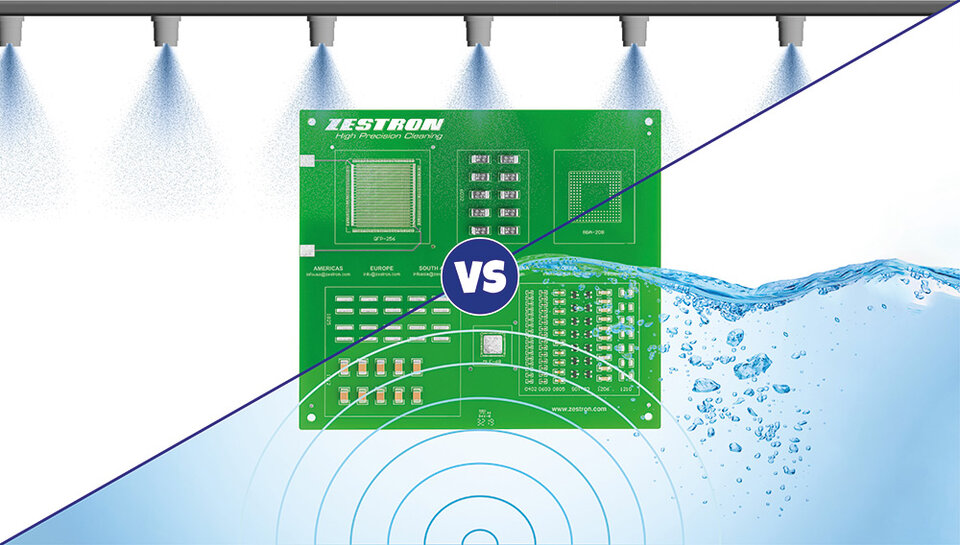

For the mechanical cleaning of assemblies after soldering, mainly spraying and dipping processes are used. While in spraying processes the cleaner is applied to the assemblies via nozzles, cleaning in immersion processes always takes place under the surface of a cleaning bath into which the assemblies are immersed.

Different processes are used to remove the flux residues:

-

Spray under Immersion

-

Ultrasound

-

Bubbling

-

PCB movement

-

and a relatively new method that works with alternating pressure

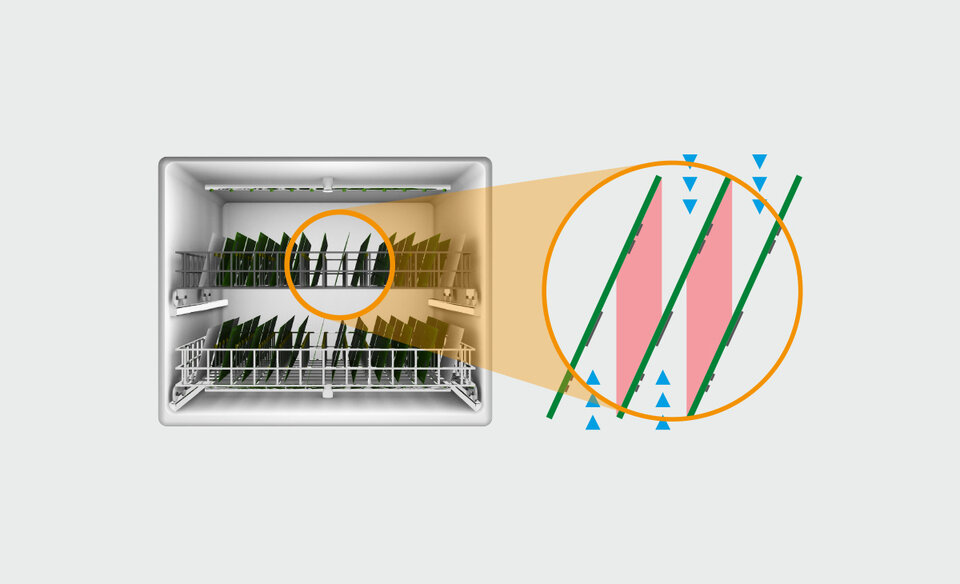

Flux removal in narrow gaps, e.g. under components, is particularly challenging. But how suitable are the processes for this?

We have checked this question in the fact-check video. You will not only learn how the above-mentioned immersion processes work, but also how good their respective cleaning performance is under components

Now, Watch the Fact Check in the Video ▼

Fact check to readImmersion Process for Cleaning Assemblies

On the Test Bench: How Do the Different Immersion Processes Work - Especially Under Components?

1 | The Basic: Functional Principle of the Immersion Process

Immersion processes always take place in a tank containing the cleaning bath. For flux removal, the assemblies are completely immersed in the bath. Depending on the process, various mechanics are used to loosen impurities.

Here is the overview:

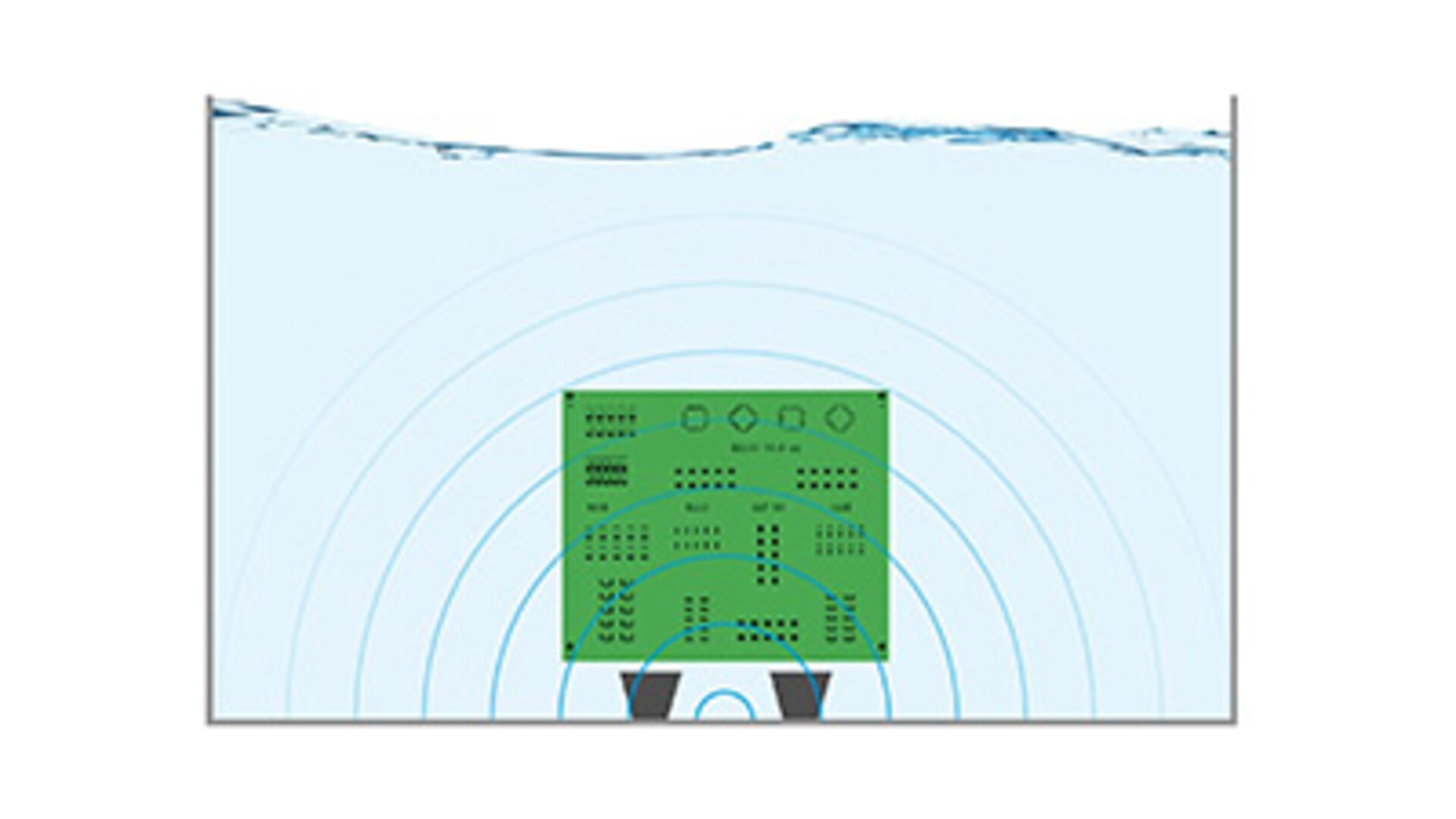

| Spray under immersion

Pumps draw in the cleaning liquid and direct it under pressure through a nozzle system under the bath surface. The jet of liquid sets the bath in motion and thus provides the cleaning effect.

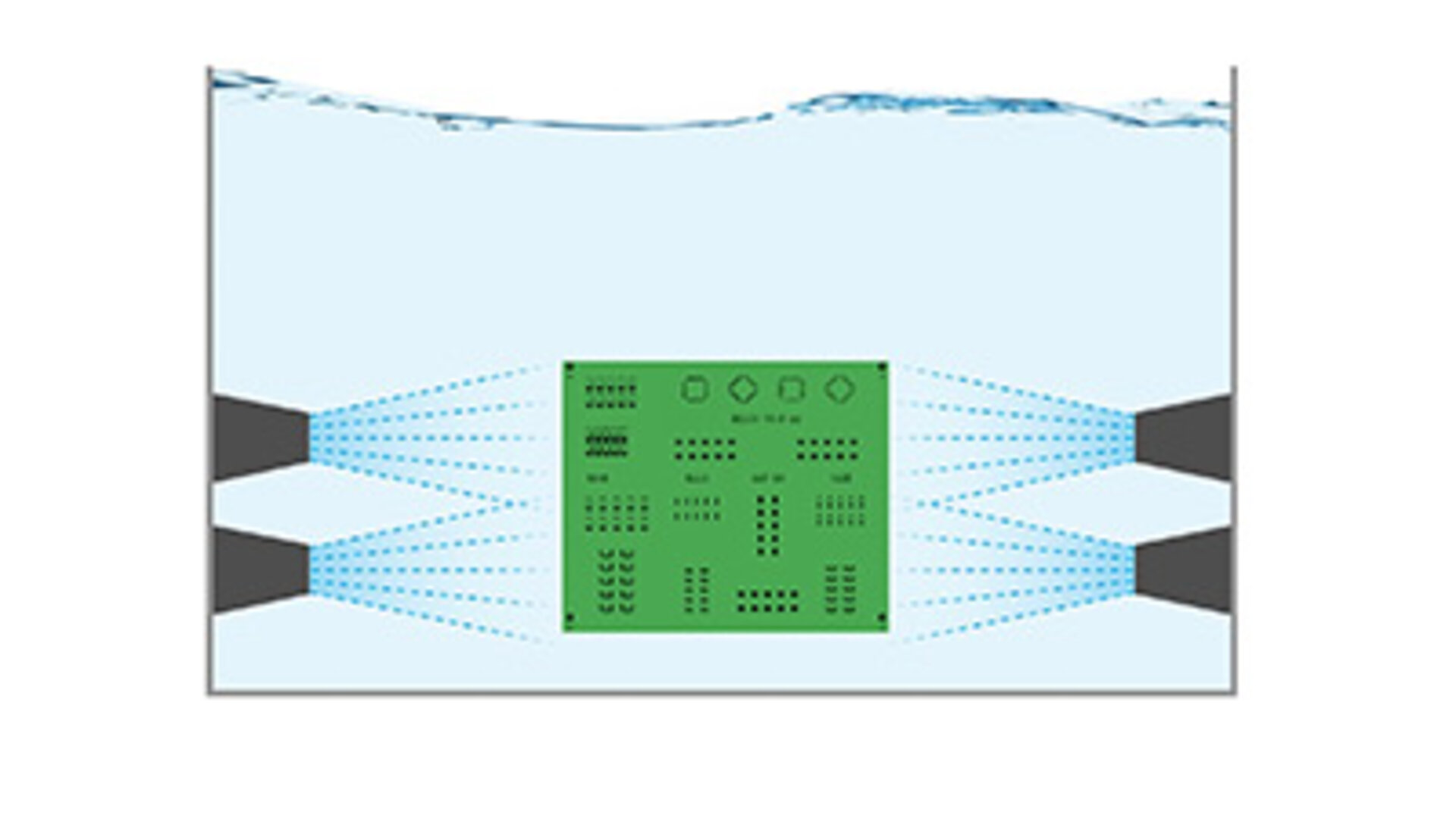

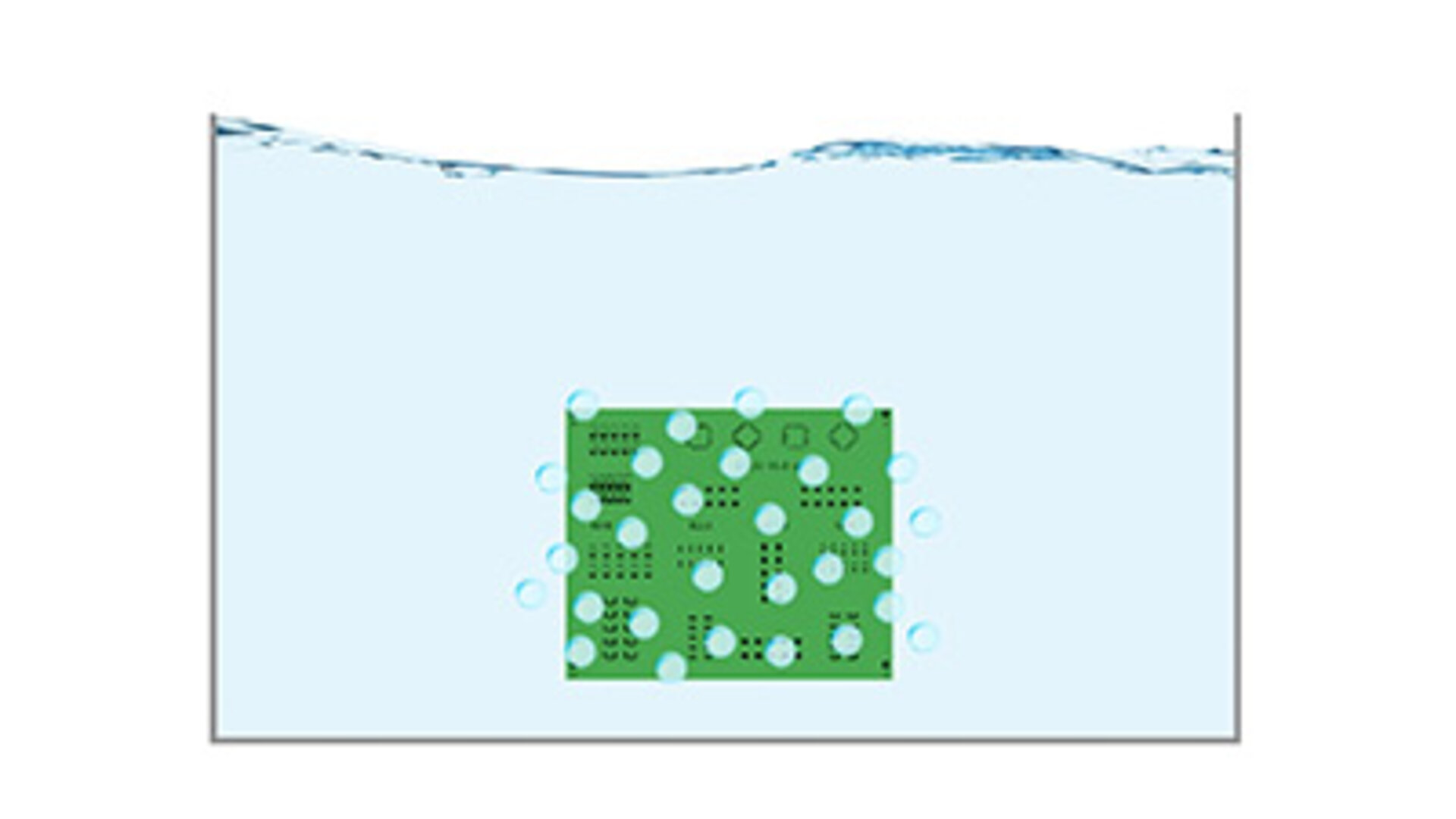

| Ultrasound

Ultrasonic vibrations of 40 – 45 kHz are introduced into the bath and generate cavitation bubbles. Their implosion dissolves the flux residues.

(You can find out more about ultrasound and whether ultrasonic cleaning damages components here)

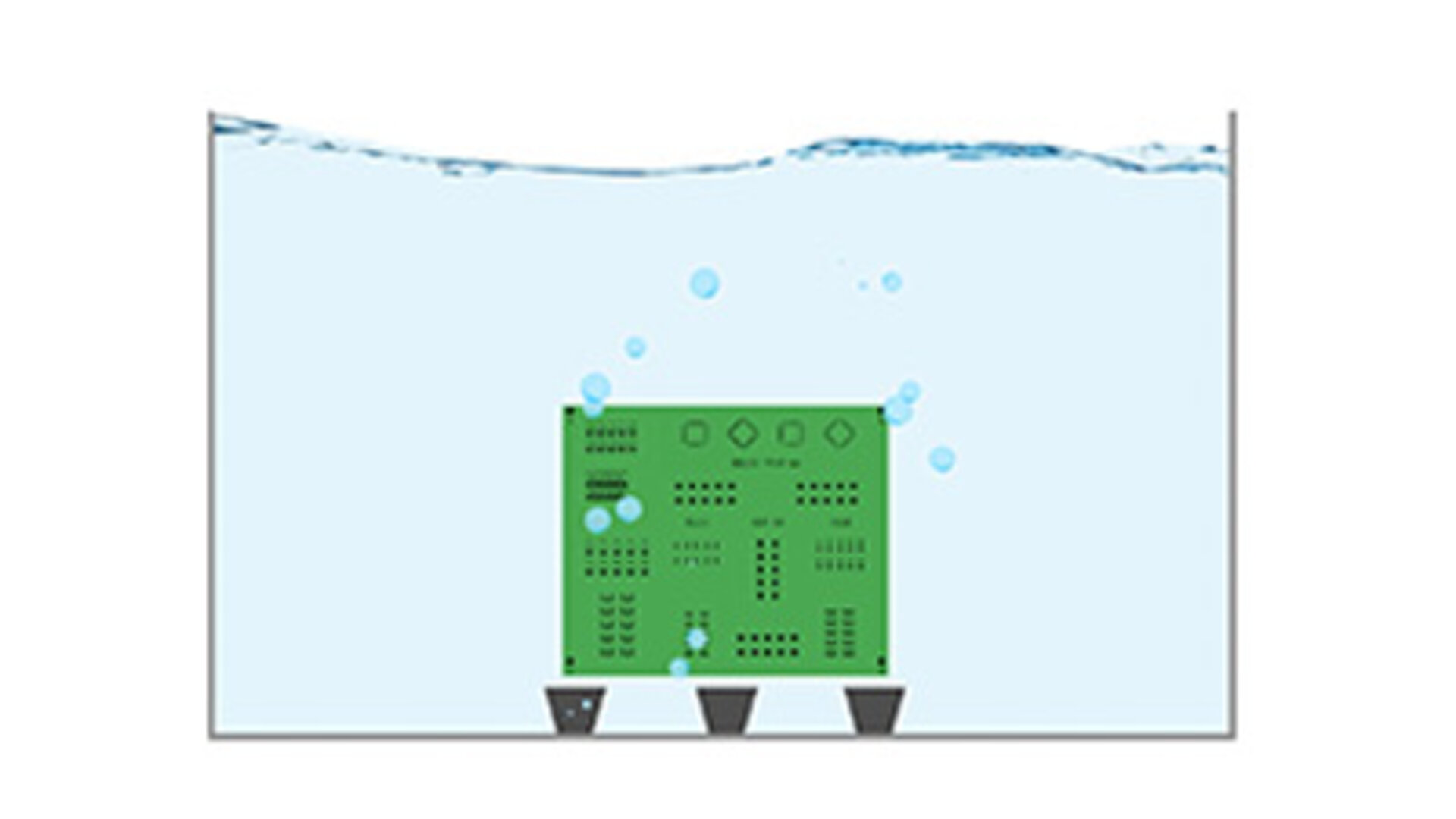

| Bubbling

Here, injected air bubbles set the bath in motion and facilitate cleaning.

| PCB Movement

With the help of product carriers, the assemblies are moved up and down in the bath.

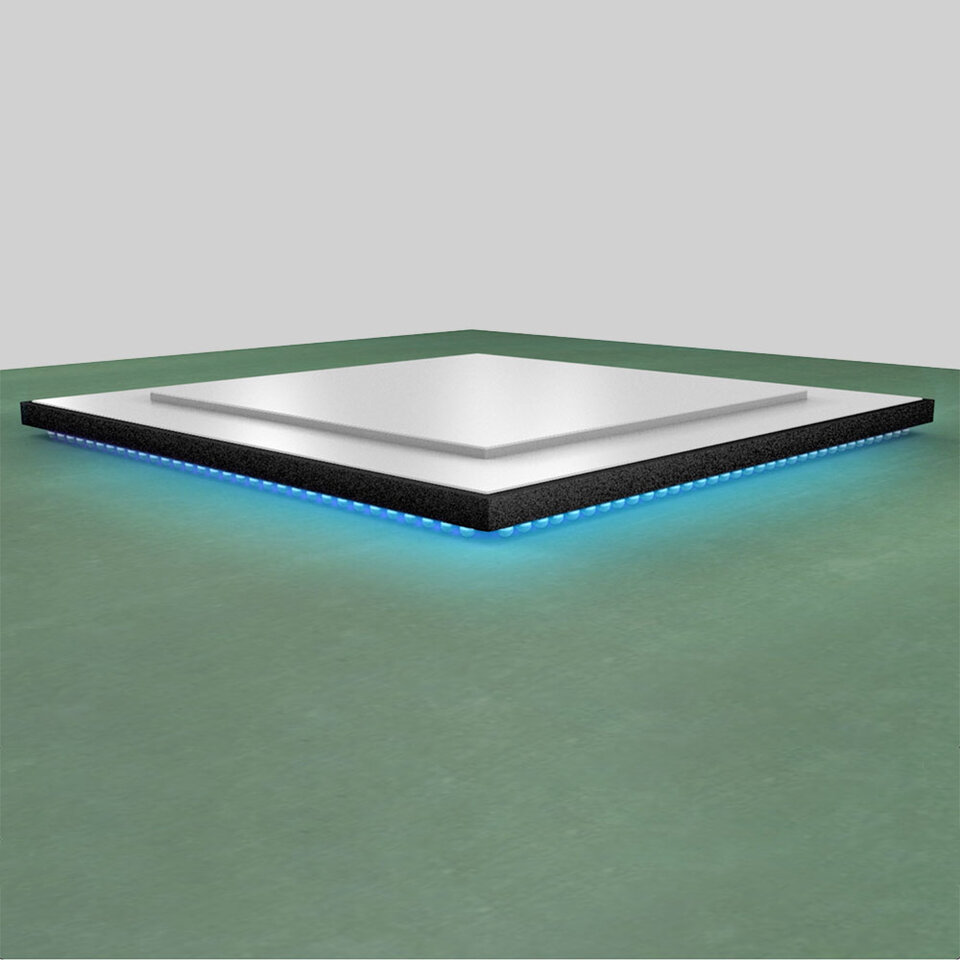

| Alternating Pressure

This is a relatively new process for cleaning assemblies. A system of pumps and valves apply cyclical pressure to the cleaning bath. Similar to ultrasound, collapsing bubbles are created, but at a lower frequency.

2 | The Scientific Test

In order to find out which process is particularly suitable for cleaning under components (low-standoffs), we carried out cleaning trials.

Several cleaning machines from different manufacturers were selected for each of the processes described above. For the tests, all machines were filled with uniform test boards. The test boards contain components with different standoffs, and a defined test dirt was also applied under the components.

After cleaning, the cleaning performance of each machine under the components was examined and evaluated.

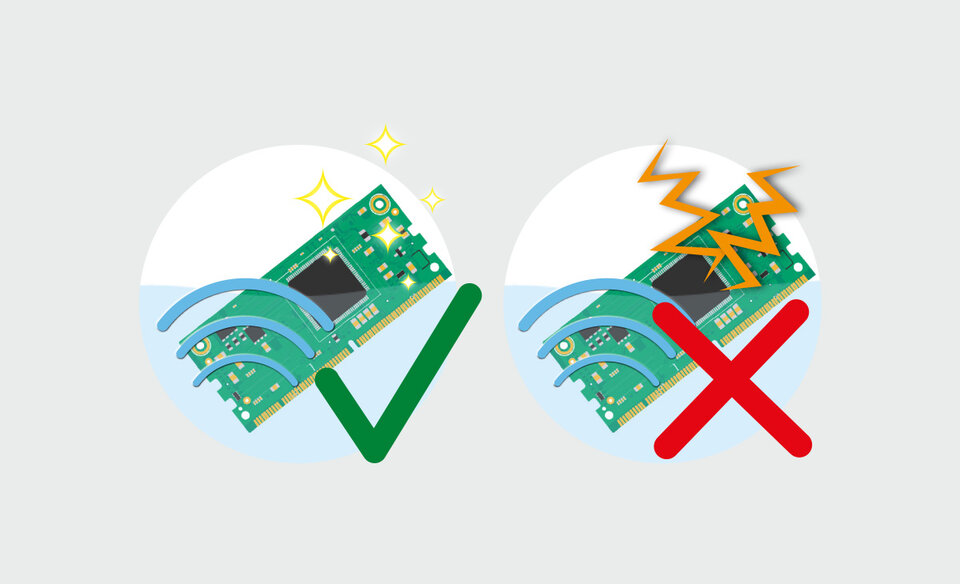

3 | The Test Results - But Please Understandable

What results did the tests deliver? And which method is particularly suitable for cleaning under components?

Ask now and we will explain in detail and in an understandable way:

-

The functional principle and the mode of action of the individual processes on the surface and under components

-

What cleaning performance the processes under components were able to achieve in the tests

-

Which processes are particularly suitable for cleaning assemblies – and which are less so