Does Shadowing Always Occur in Dishwashers for PCBs?

Time for a fact checkPCB Cleaning Using the Dishwasher Principle

On the Test Bench: Does Shadowing Always Occur in Dishwashers for PCBs?

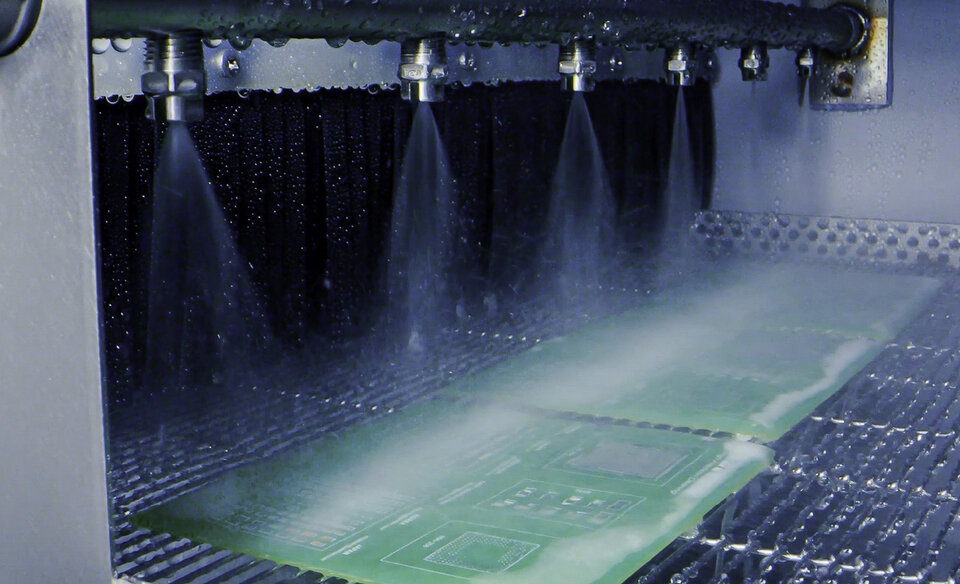

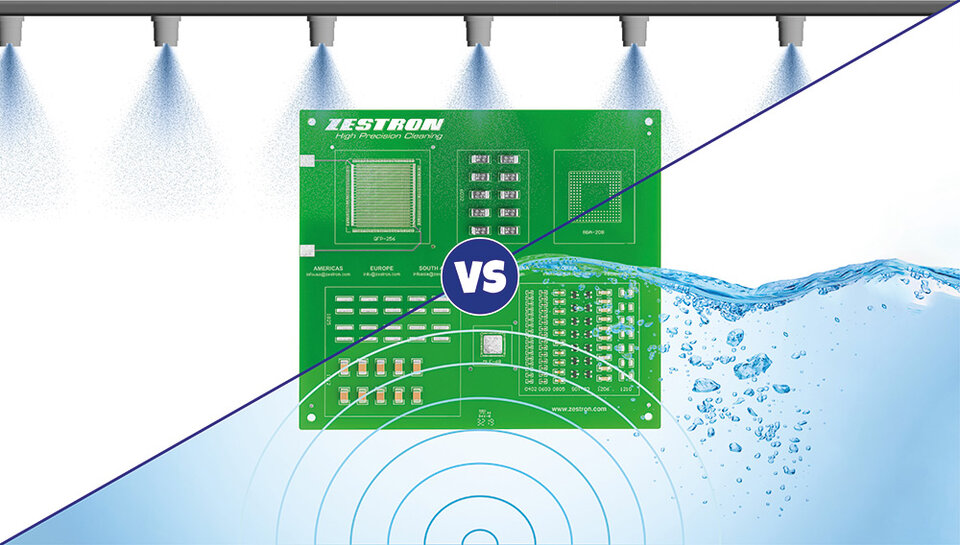

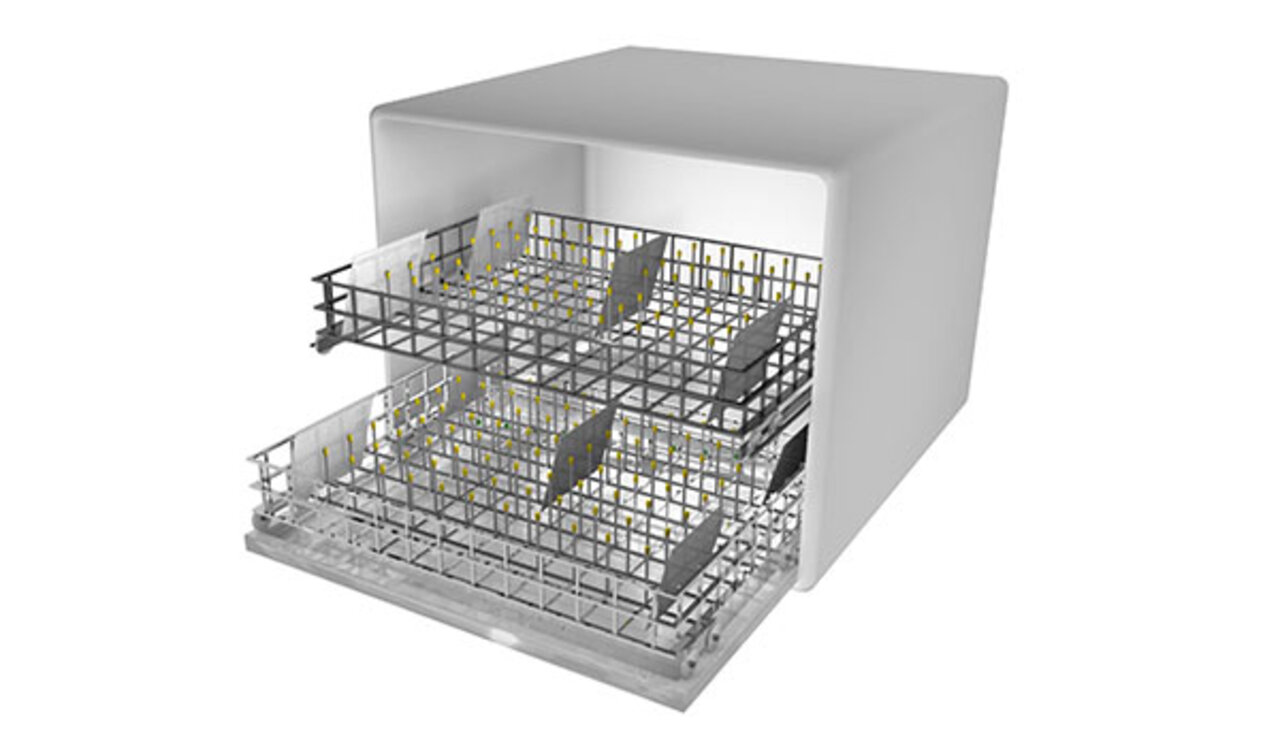

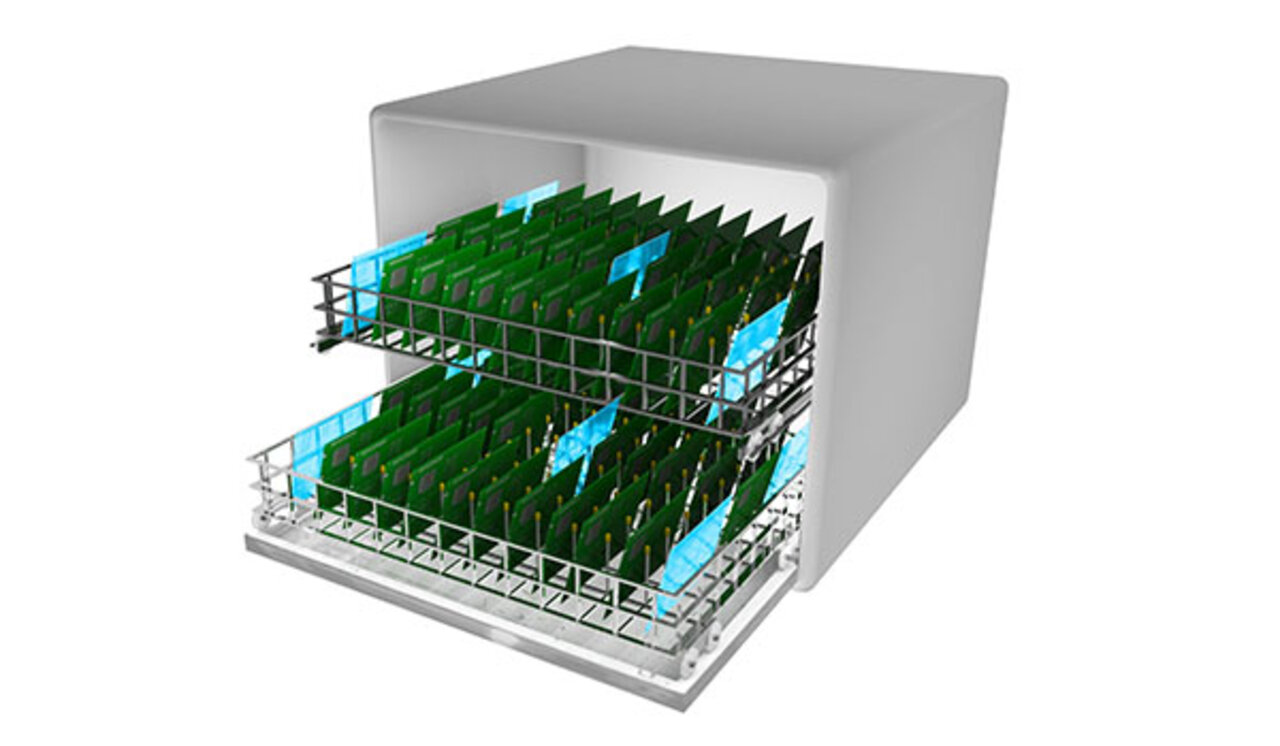

Machines that function like a dishwasher are suitable for cleaning small and medium quantities of PCBs. The PCBs are placed in baskets and cleaned, rinsed and dried in a single chamber. From the dishwasher we know the phenomenon that parts do not get clean because they are covered by others. So do such shadowing effects also occur in dishwashers for PCBs – so-called single-chamber batch systems?

In the video you will learn how differently „dishwashers“ for PCBs are configured, where the assumption of shadowing comes from and with the help of which tests we have checked the question.

Now, Watch the Fact Check in the Video ▼

Fact check to readBatch Cleaning Systems for Printed Circuit Boards

On the Test Bench: Does Shadowing Always Occur in Dishwashers for PCBs?

1 | The Basis: What is Shadowing?

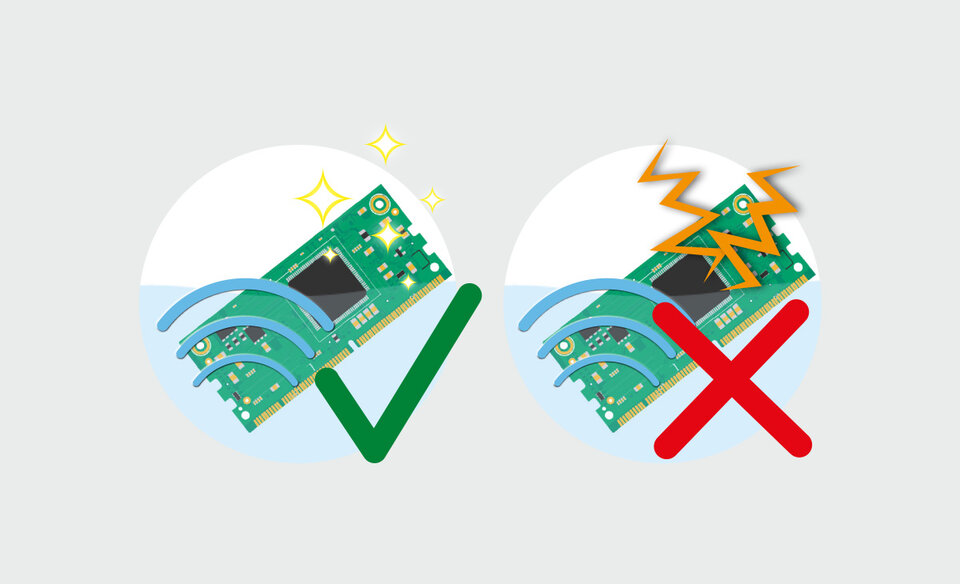

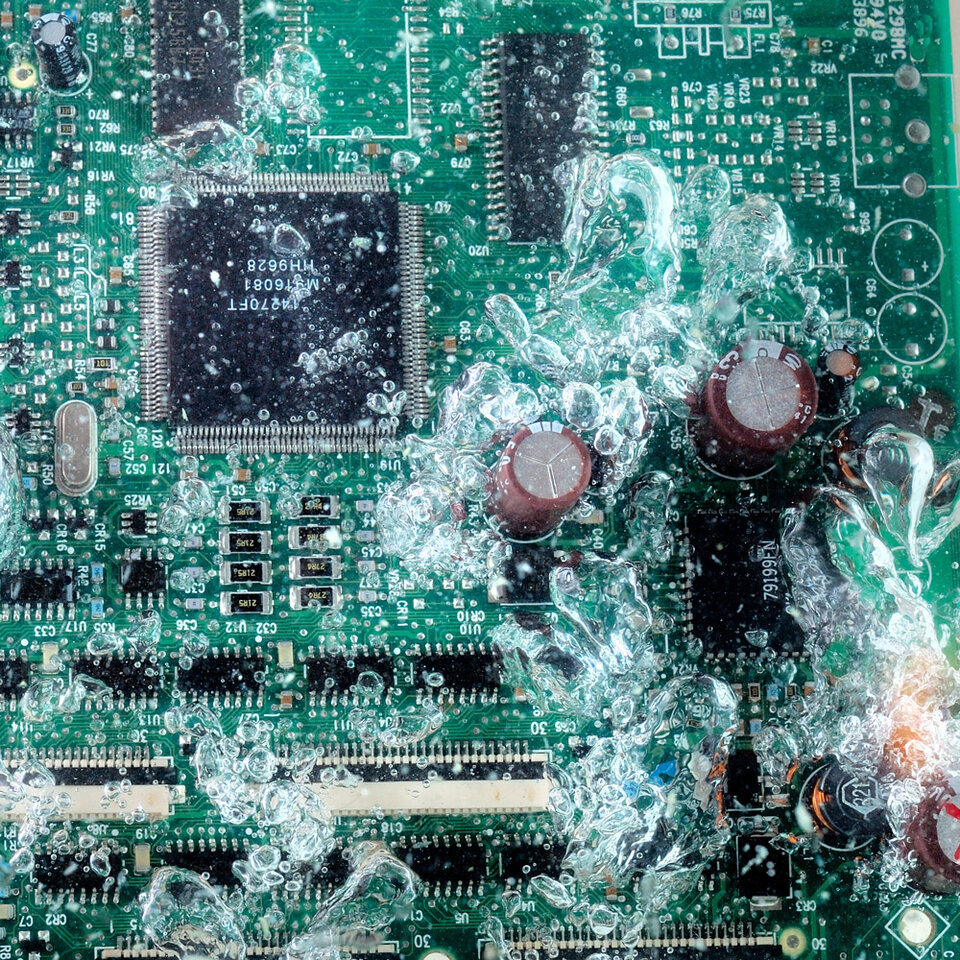

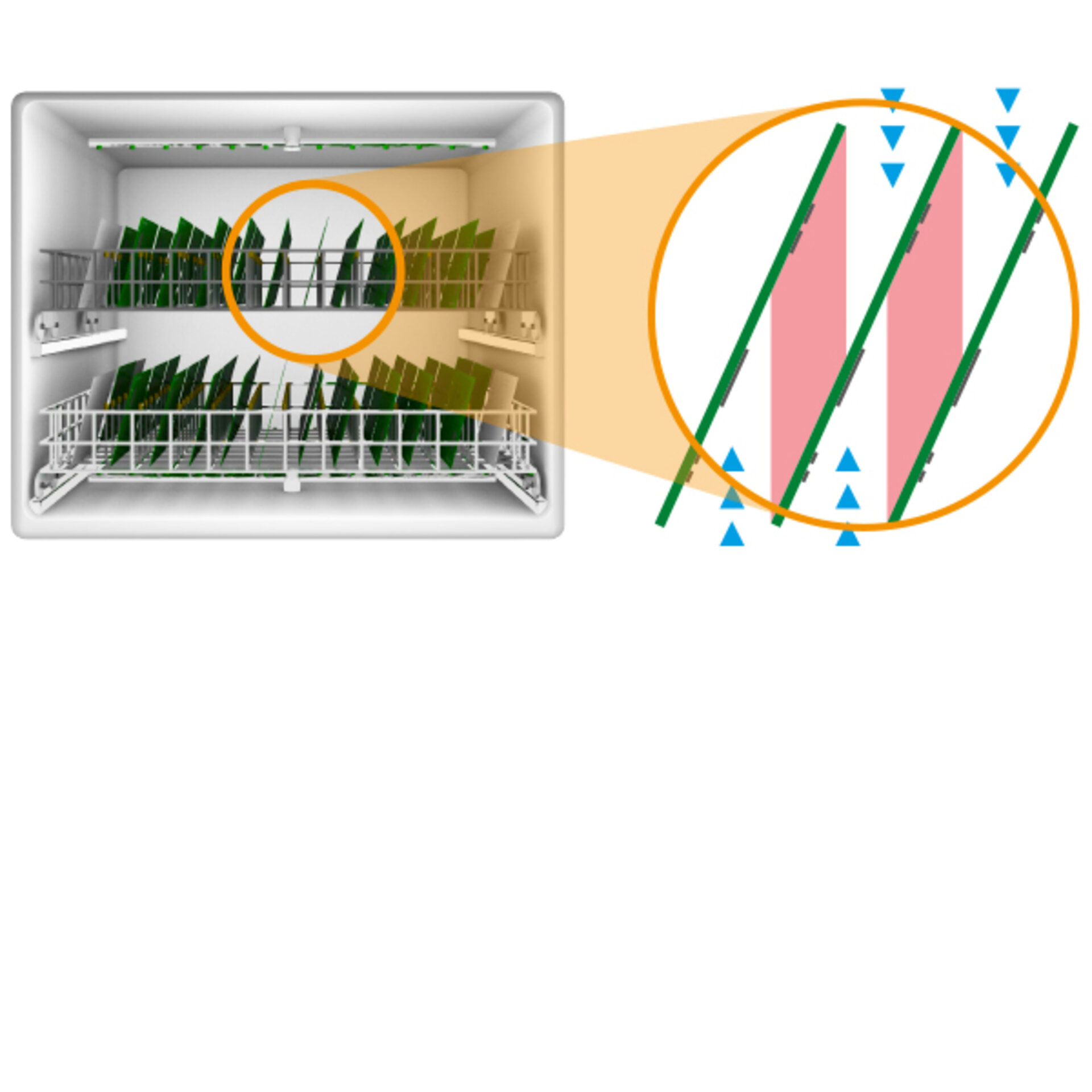

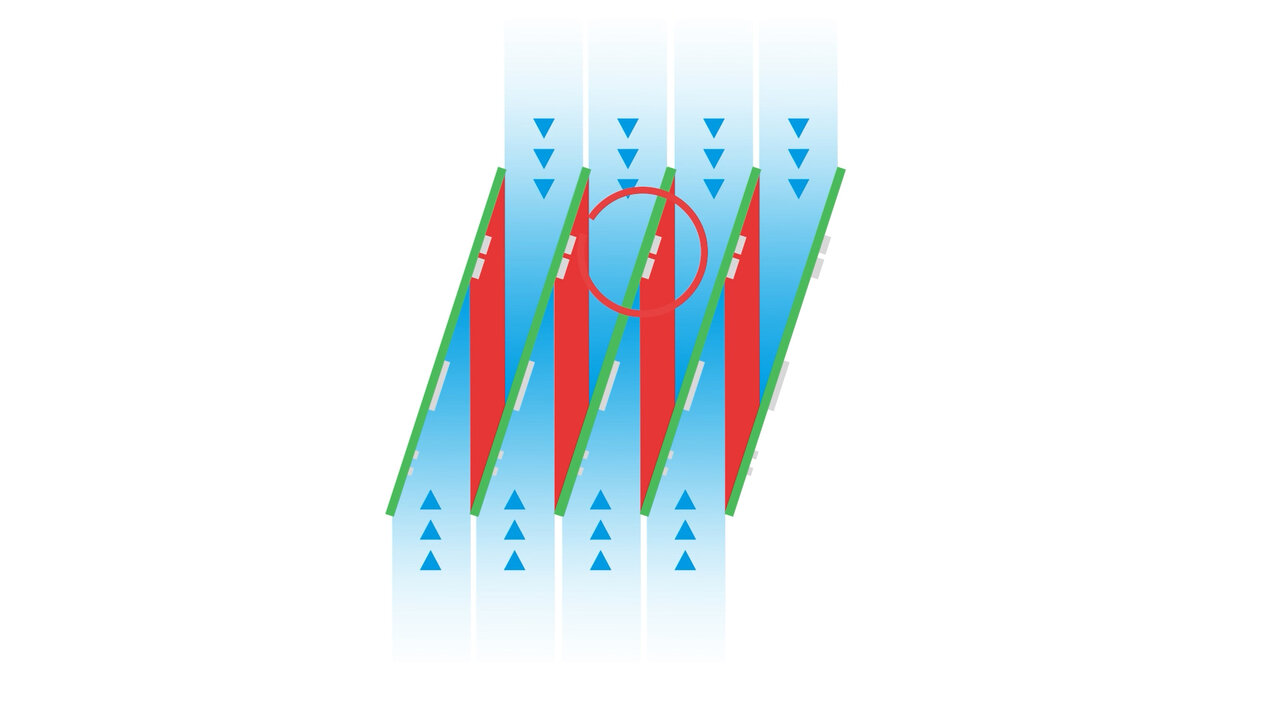

The more densely a single chamber batch cleaning system is filled with PCBs, the higher the probability that the assemblies will cover each other – this phenomenon is called “shadowing”. Usually, the substrates come into contact with the cleaning agent from above and below, or from two sides. As a result, it is never possible to spray cleaner on all directions and angles. In addition, it can also happen that individual larger components on the assembly lead to the shadowing of certain areas.

This would mean that there would always be areas on the boards that experience shadowing and the cleaning result would be worse in these areas or a longer cleaning time would be needed to achieve good results.

2 | Scientific Testing

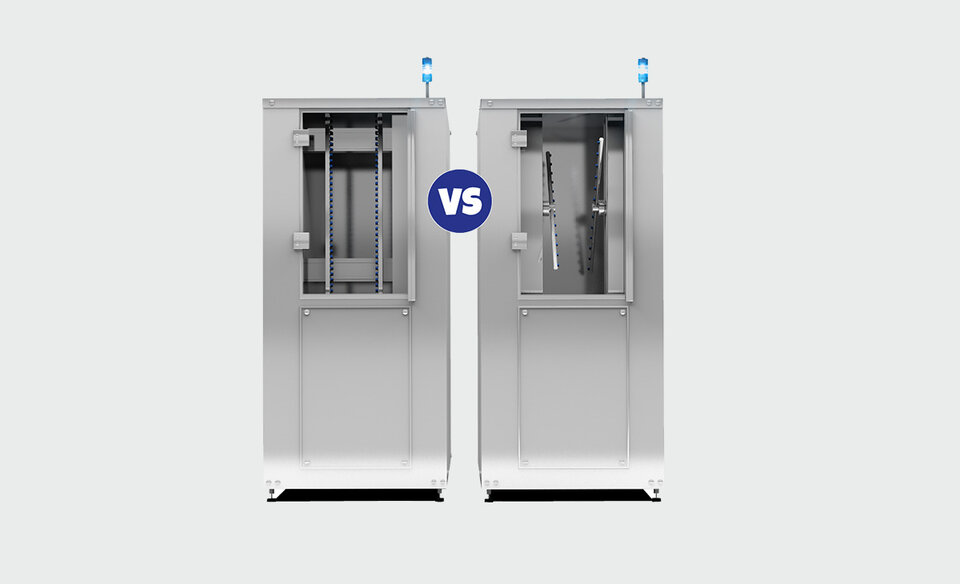

In order to find out whether shadowing always occurs during PCB cleaning with dishwashers, cleaning systems with different configurations were selected and tests were carried out.

Empty run:

Initially, only a few specially manufactured, assembled glass boards contaminated with test flux were cleaned in each system. This allowed the cleaning performance to be defined without the risk of shadowing by other assemblies.

Fully loaded:

Each system was then reloaded with the glass boards at the same position and the rest of the baskets were filled with standard assemblies of the same size. These cleaning trials created the conditions for potential shadowing to occur.

We compared the cleaning results under the components of the glass boards of the empty runs with the results of the fully loaded ones of each machine.

➞ Could we prove shadowing effects in the experiments? And do the different machine configurations have an influence on shadowing?

Are You Curious?

Ask for the test results now and you will find out in detail:

-

whether shadowing was detectable in dishwashers for PCBs

-

if so, what effects this had on the cleaning results

-

whether shadowing can be avoided by certain system configurations

-

whether the angle of inclination and positioning of the assemblies in the basket play a role