Cleaning PCBAs Using Ultrasound or Spraying: Which Process Fits Which Requirement?

time for a fact checkUltrasonic or Spray Cleaning

On the Test Bench: Which Process for Which Requirement?

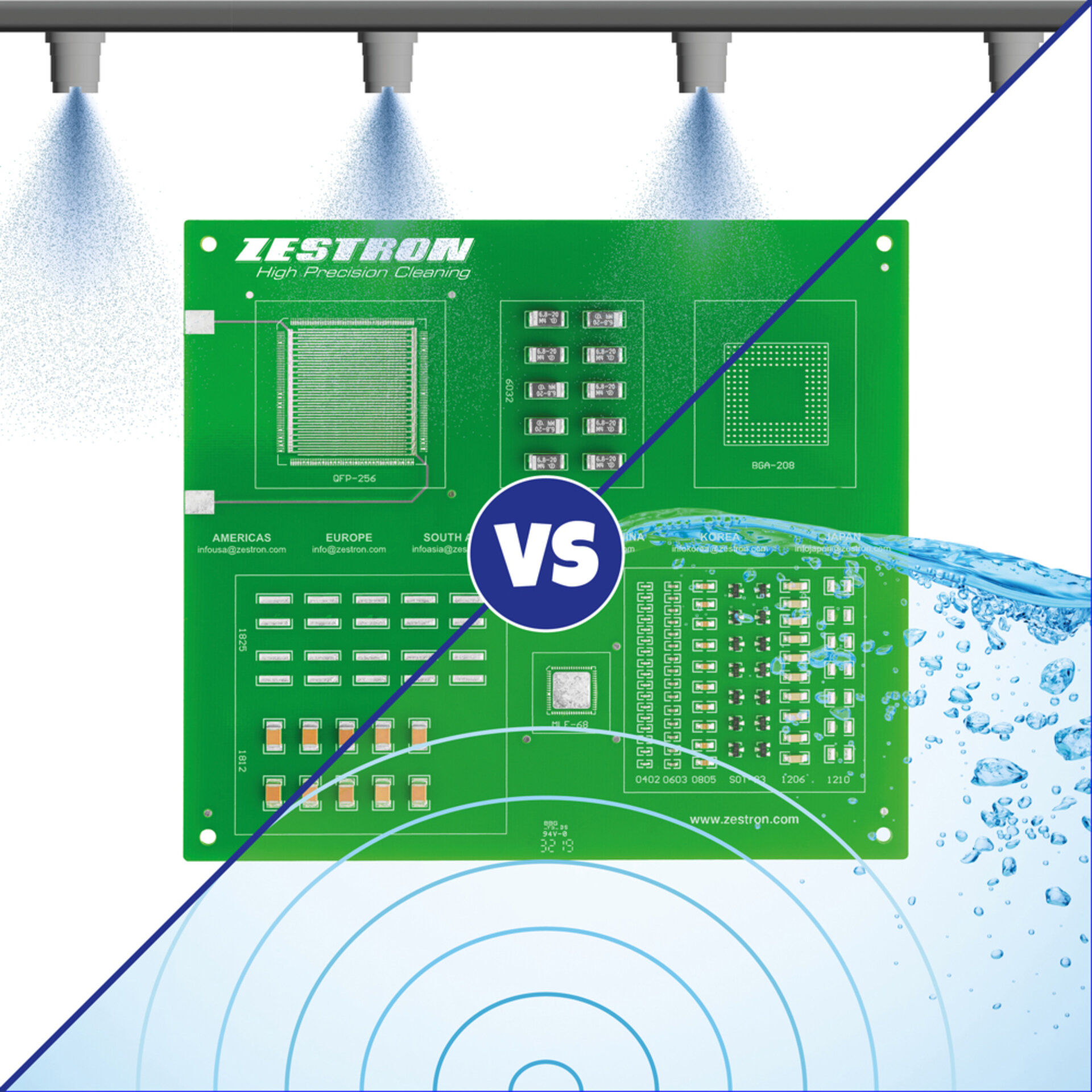

Ultrasonic and spray cleaning are proven and widely used processes for removing flux from the surface of assemblies. But as a manufacturer, how do you decide which of the two methods is the right one for the cleaning process you need? It depends on the individual cleaning requirements. In addition to the question "How clean should it be?", these factors also play an important role when deciding on a cleaning process: the production throughput and therefore the size of the system, as well as the ability to automate the process.

Do you need guidance? The fact check gives you a compact overview of the cleaning processes and different systems and tells you which process is suitable for which cleaning challenge.

Watch the Fact Check in the Video ▼

fact check to readUltrasonic And Spraying

On the Test Bench: Cleaning Processes And Systems

Ultrasonic Cleaning - Immerision in Several Tanks

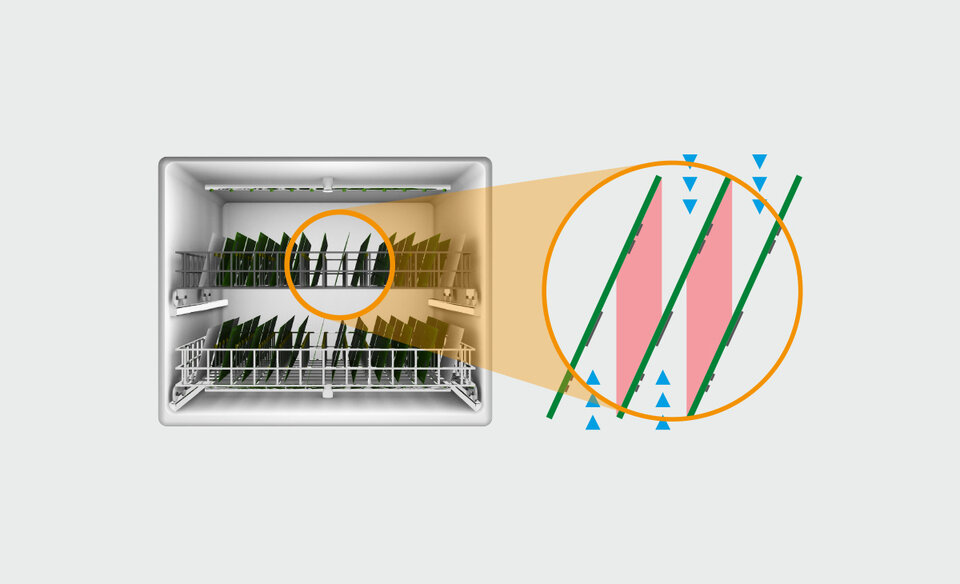

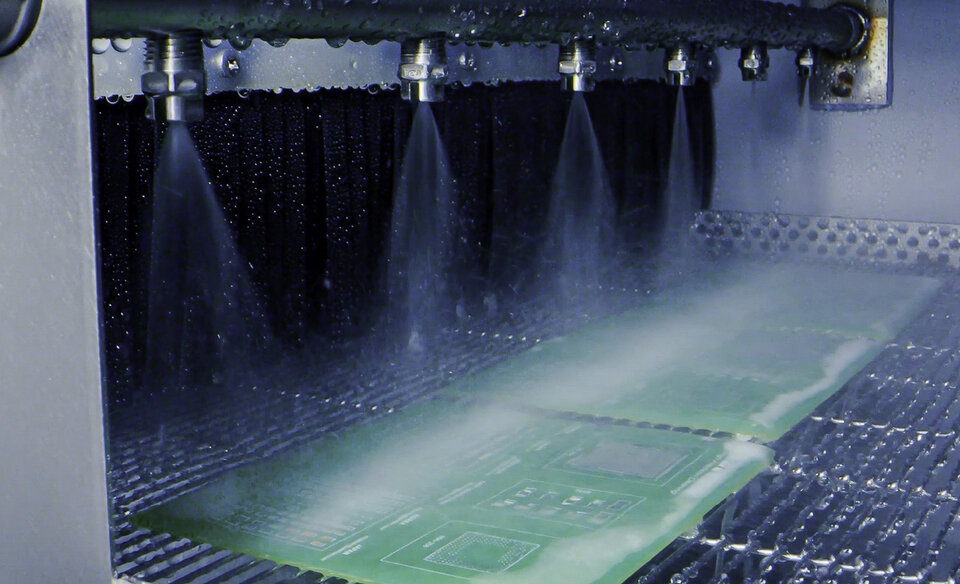

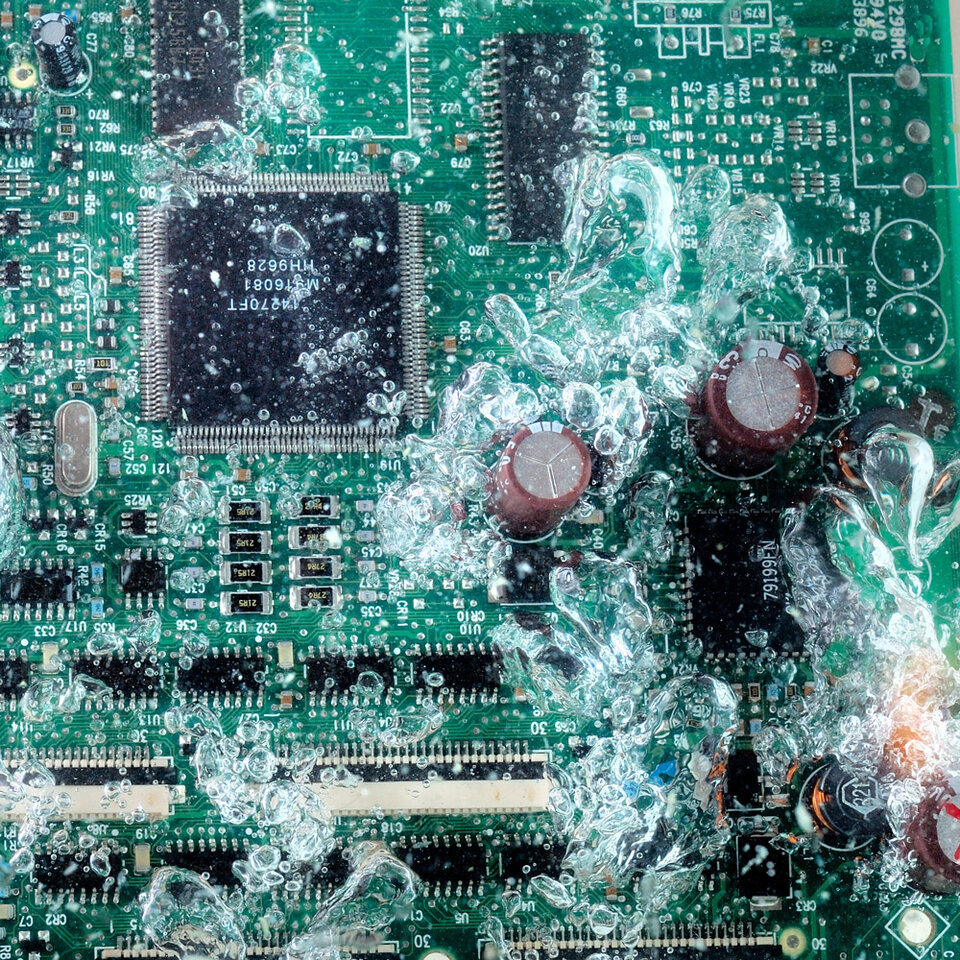

PCBAs are cleaned using ultrasound in immersion tanks with ultrasound generators. The ultrasound emitted creates growing, so-called cavitation bubbles in the cleaning bath, which implode and thus remove impurities from the assembly.

The cleaning systems consist of several tanks for cleaning, rinsing and drying.

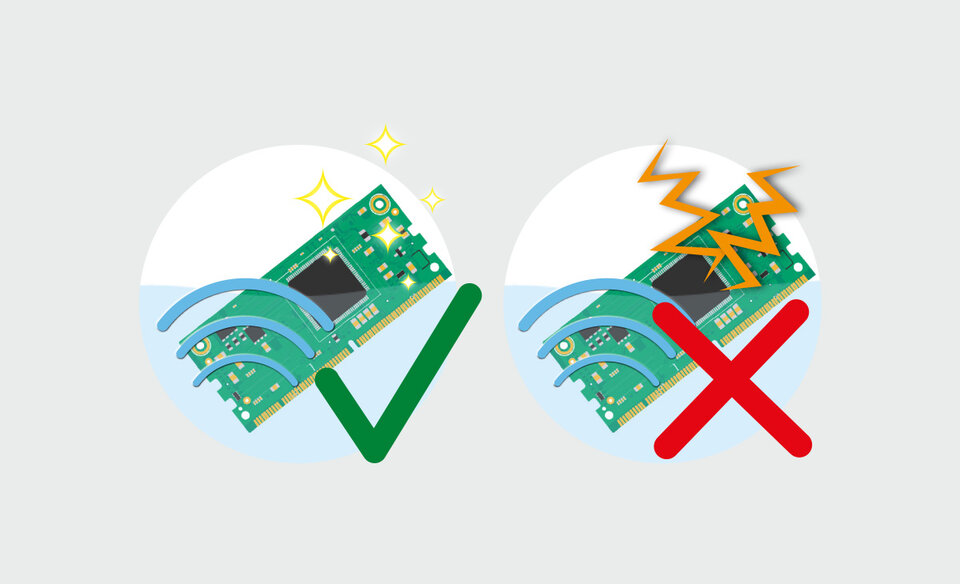

Are you concerned that ultrasound could damage sensitive components?

Find the answers in this fact check

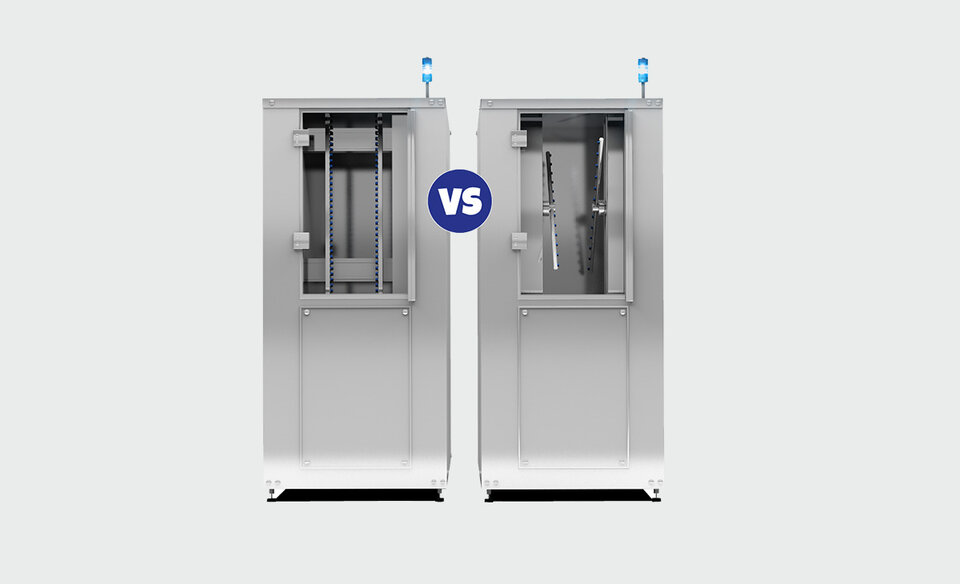

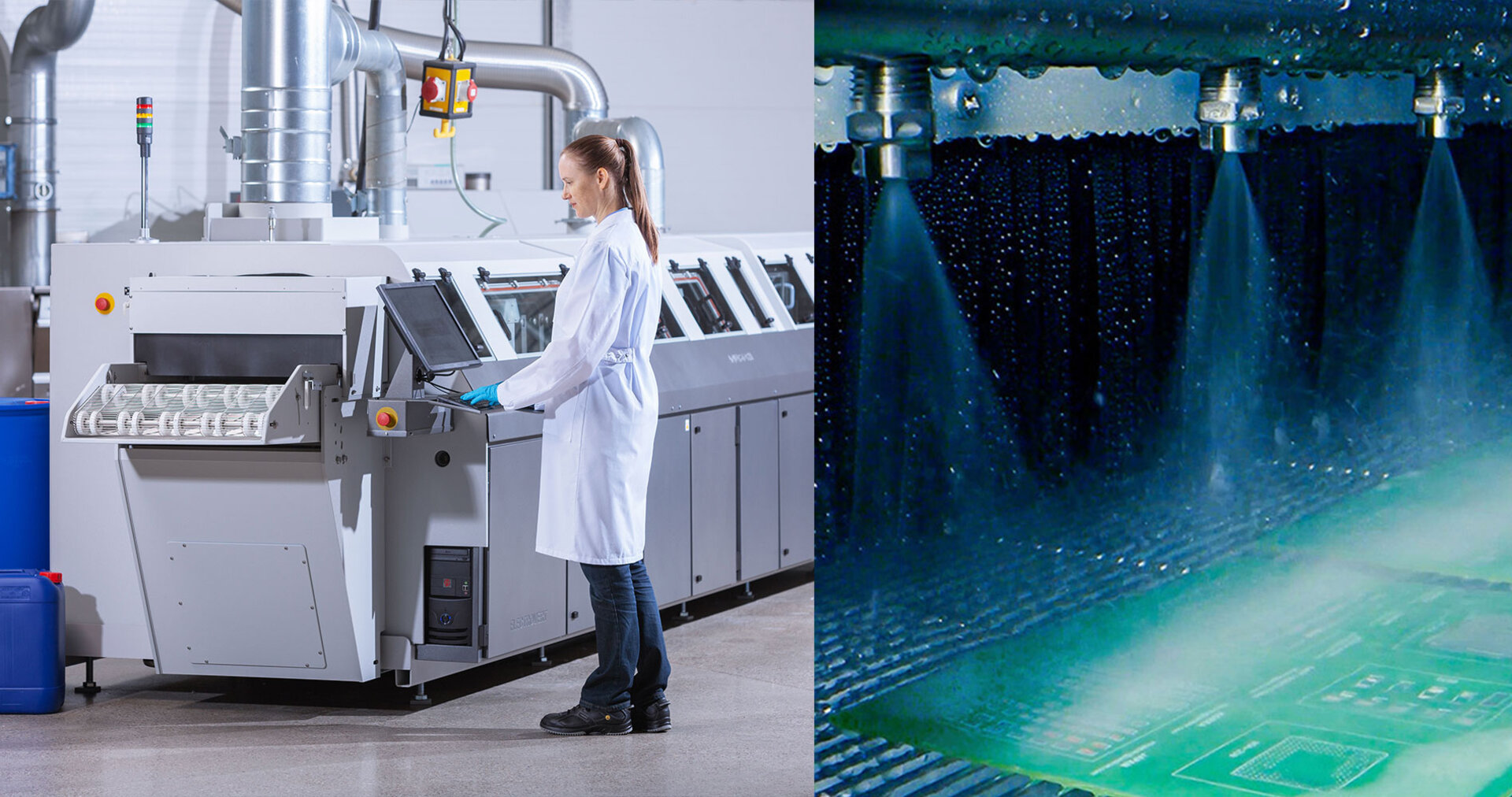

Spraying Systems - "Dishwasher" or Fully Automated?

There are two types of spraying systems. So-called batch systems work in a similar way to a dishwasher and consist of a single chamber for cleaning, rinsing and drying. The assemblies either stand in baskets or are clamped in product carriers. Depending on the configuration, the system has two to four spray arms that either rotate or move linearly over the assemblies.

There are also inline systems that can be integrated fully automatically into the production line. Here, the assemblies pass through the system on a conveyor belt and are cleaned under fixed spray arms.

the fact checkWhich Process for Which Requirement?

Removing flux and other contaminants from electronic assemblies in spray or ultrasonic cleaning systems is a proven and established procedure. Nevertheless, there are reservations, frequently asked questions or assumptions about both processes and the cleaning machines.

We have already resolved some of these in our Fact Checks.

In any case, the decisive factor is the individual cleaning challenge or question posed by the manufacturer, e.g. where on the assembly does it need to be clean and how? However, the following three factors should also not be underestimated:

-

Throughput or cycle time of a machine

-

The size of the system or its space requirements

-

The degree of automation of a system and the manual effort required to operate it

We do the fact check and have tested standard series cleaning systems on the market to find out which process is the right one for which requirement.

Curious to Find Out More? Then Enquire Now And Find Out More About:

-

The cleaning principle of spray and ultrasonic systems.

-

How the systems differ in terms of size, throughput or cycle time and automation options.

-

The structure of our cleaning tests and the results.

-

Which process is best suited for which cleaning challenge, e.g. sub-component cleaning.