Does PCB Cleaning with Ultrasonic Damage Electronic Components?

TIME FOR A FACT checkPCB Cleaning with Ultrasonic

On the Test Bench: Are Electronic Components Damaged by Ultrasonic Cleaning?

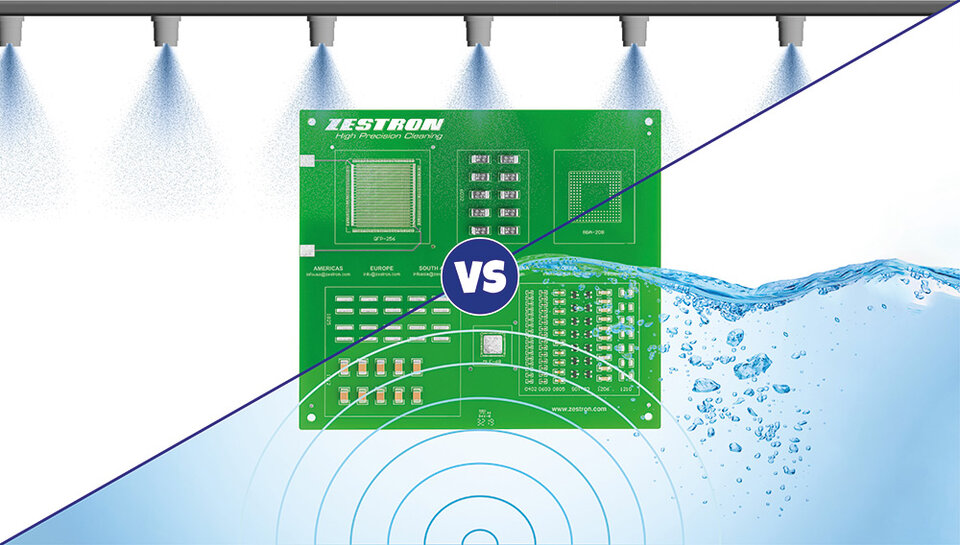

Immersion cleaning with ultrasound is a widespread process in electronics manufacturing that has been used for decades to remove flux residues from assemblies after soldering. Areas under components that are difficult to access and narrow gaps can be cleaned well with this method. However, the process is suspected of damaging components.

But is that true? We have checked this question in the Fact Check. Find out how assembly cleaning with ultrasound works, what role the parameters frequency and power play and what damage is suspected.

Now, Watch the Fact Check in the Video ▼

fact check to read:Ultrasonic Cleaning for Electronic Assemblies

On the Test Bench: Are Electronic Components Damaged by Ultrasonic Cleaning?

1 | The Basis: How Does Cleaning with Ultrasound Work?

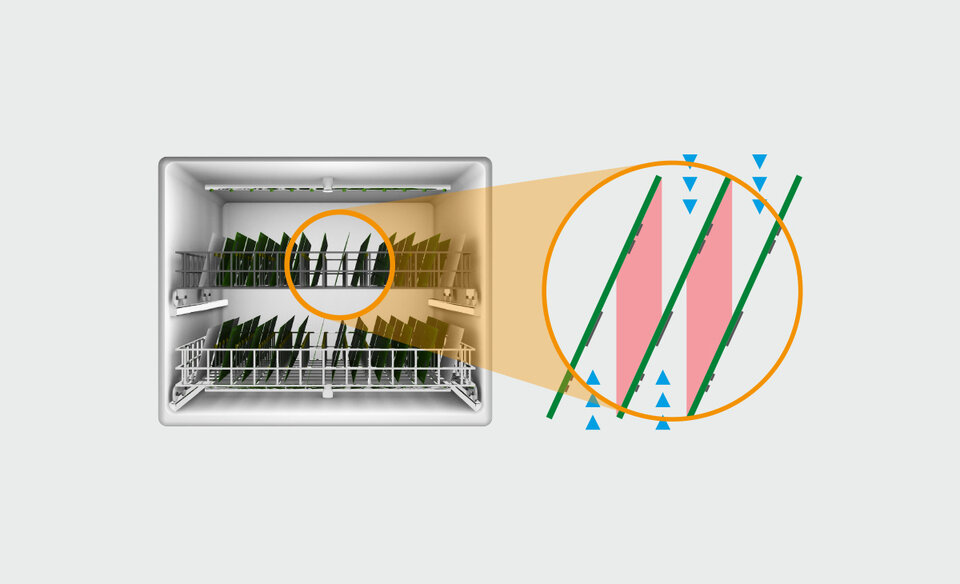

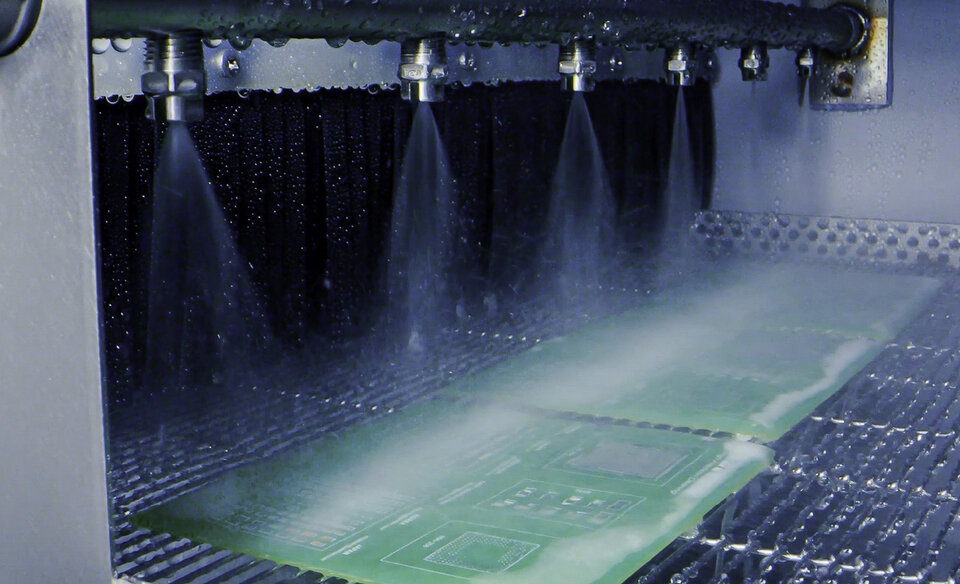

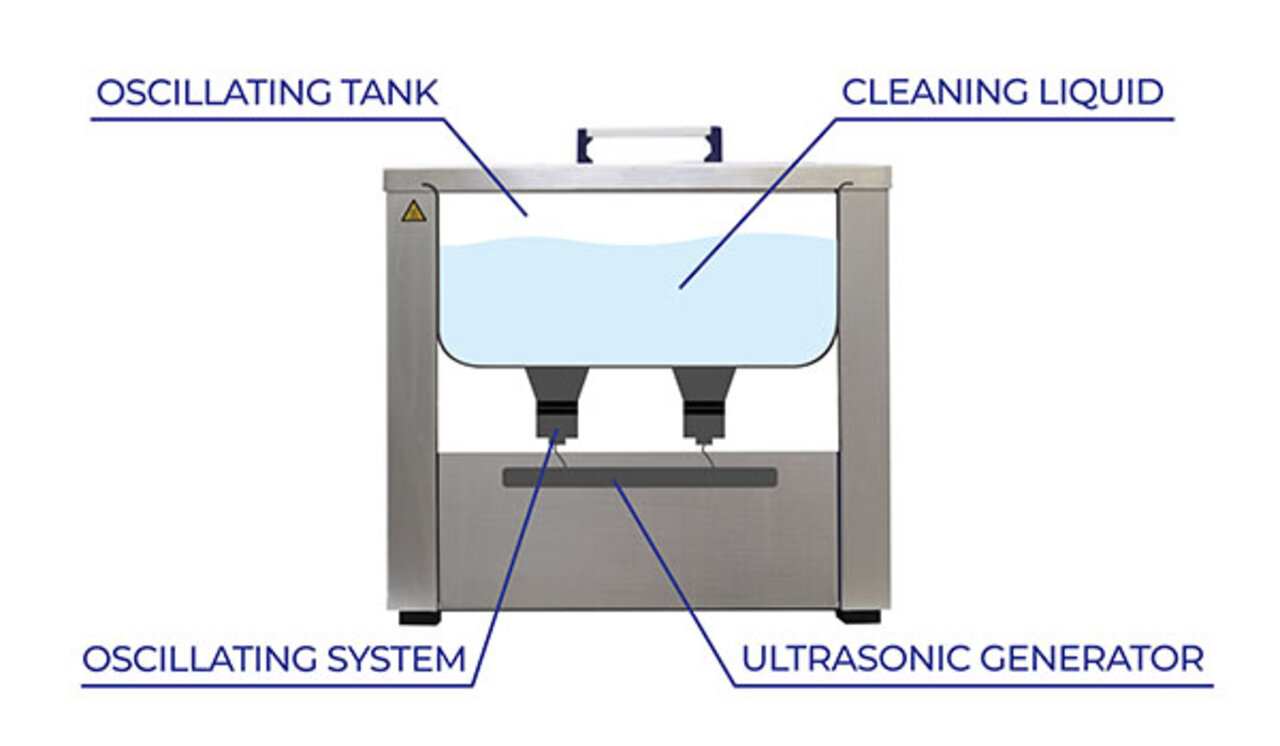

PCB cleaning with ultrasonic is carried out in special systems. They consist of an oscillating tank for the cleaning liquid, oscillating systems and an ultrasonic generator. For cleaning, the assemblies are immersed in the liquid. Vibrations in the ultrasonic range are then introduced into the liquid by the generator and the oscillating systems.

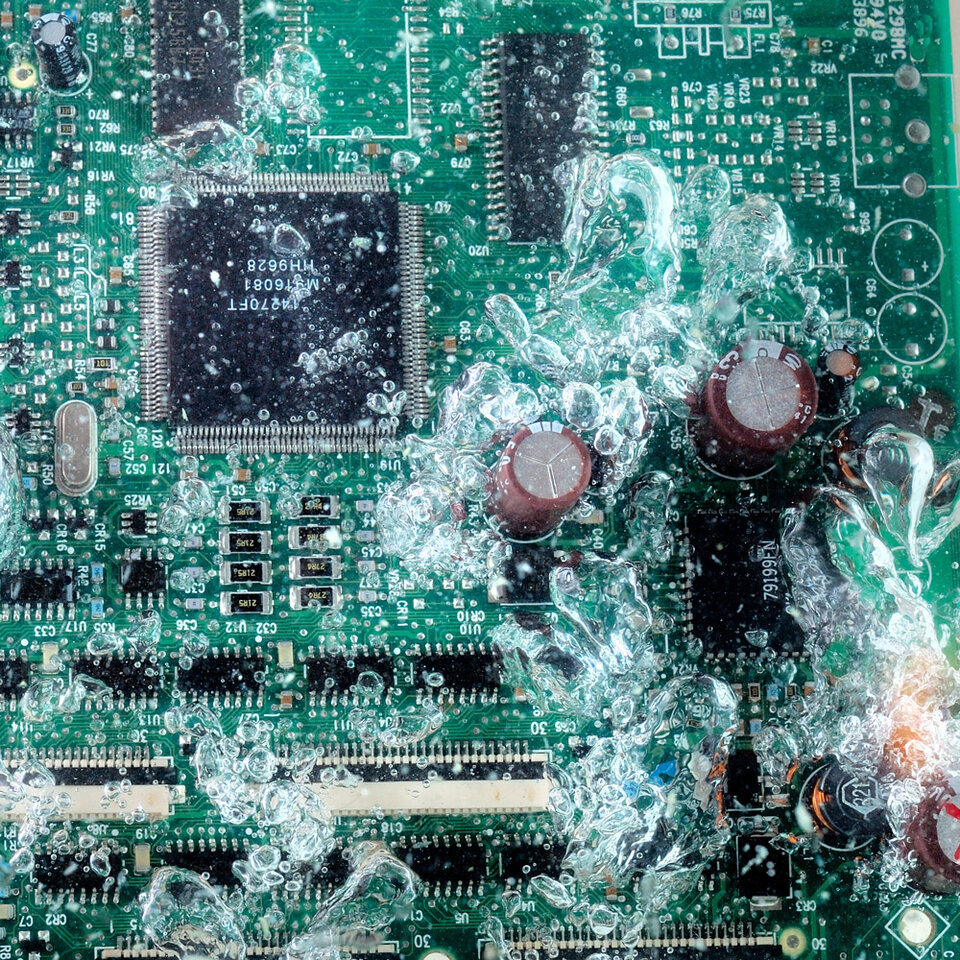

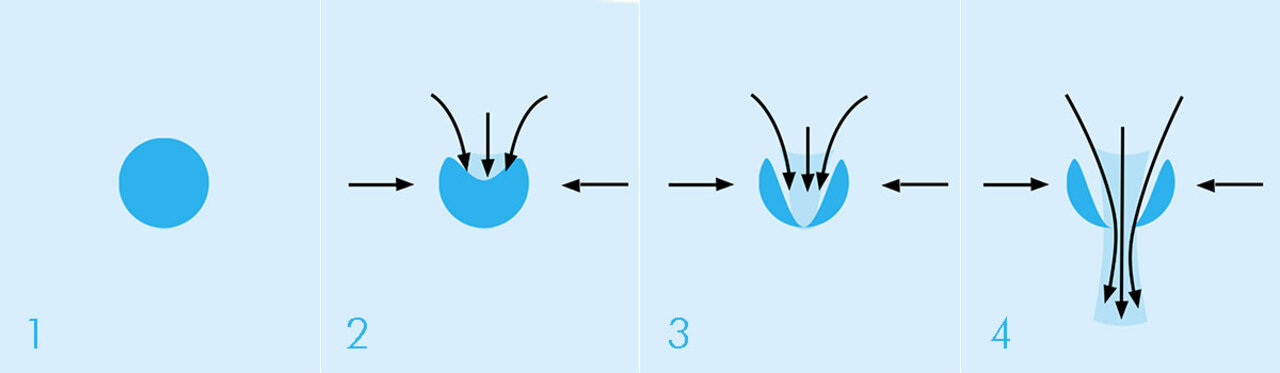

The vibrations create growing bubbles in the liquid that are invisible to the human eye – so-called cavitation bubbles. As the bubbles grow, they implode. The implosion creates a jet of liquid that dissolves impurities on the assembly.

2 | The Question: How Does Ultrasound Cause Damage?

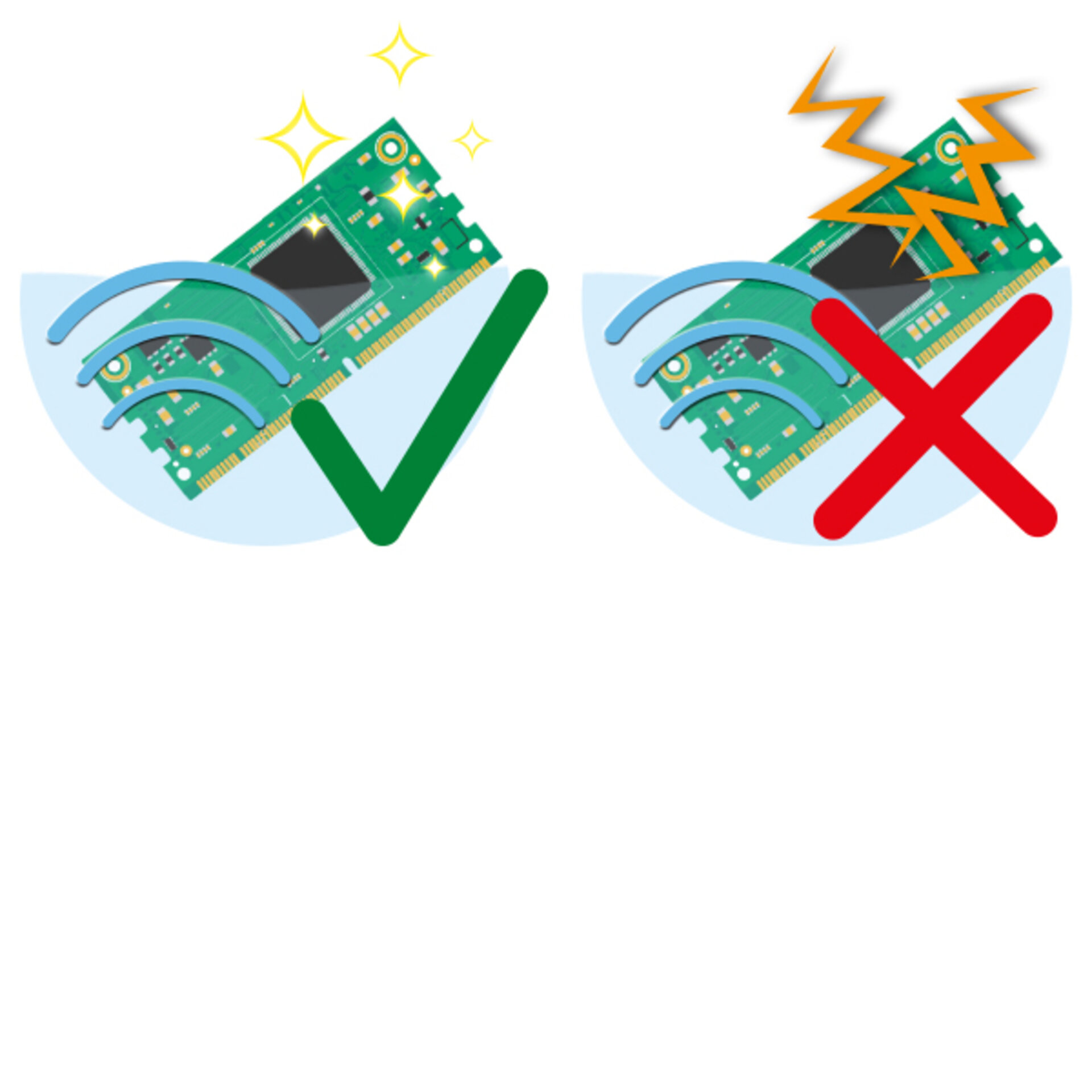

The frequency of the ultrasound plays a decisive role here. The frequency refers to the number of vibrations that are introduced into the cleaning bath per second. Ultrasound starts at frequencies of 20 kHz (kilohertz) and is not audible to humans. This means that 20,000 vibrations per second are introduced into the cleaning fluid. These vibrations can cause concern to components that can generate vibrations themselves and contain, for example, a piezoelectric quartz crystal for this purpose. The component can be set into resonance by the ultrasound and lead to damage inside.

But the cavitation bubbles that loosen the contamination are also suspected of damaging assemblies through the pressure wave of the implosion. They are influenced by the frequency as well. And the power, i.e. the energy in the cleaning bath, also comes takes effect here.

But why is cleaning of assemblies with ultrasonic used so often? Does this mean that PCBs can be cleaned in an ultrasonic bath without hesitation?

3 | The Test Results - But Please Understandable

Have you often asked yourself these questions?

Then request now, and we will explain to you in detail and in an understandable way:

-

What role the power and the frequency play

-

What possibilities there are to avoid damage by ultrasound

-

Whether only certain electronic components are sensitive to ultrasonic cleaning

-

What to look for when choosing an ultrasonic cleaning process

-

Which tests you should carry out for the selection