PCB Cleaning Machine: Do Linear or Rotating Spray Arms Clean Better?

Which PCB Washing Process Is More Effective in which case.

Time for a Fact checkPCB Washing Process With Spray Arms

On the Test Bench: Do Machines with Linear or Rotating Spray Arms Clean Better?

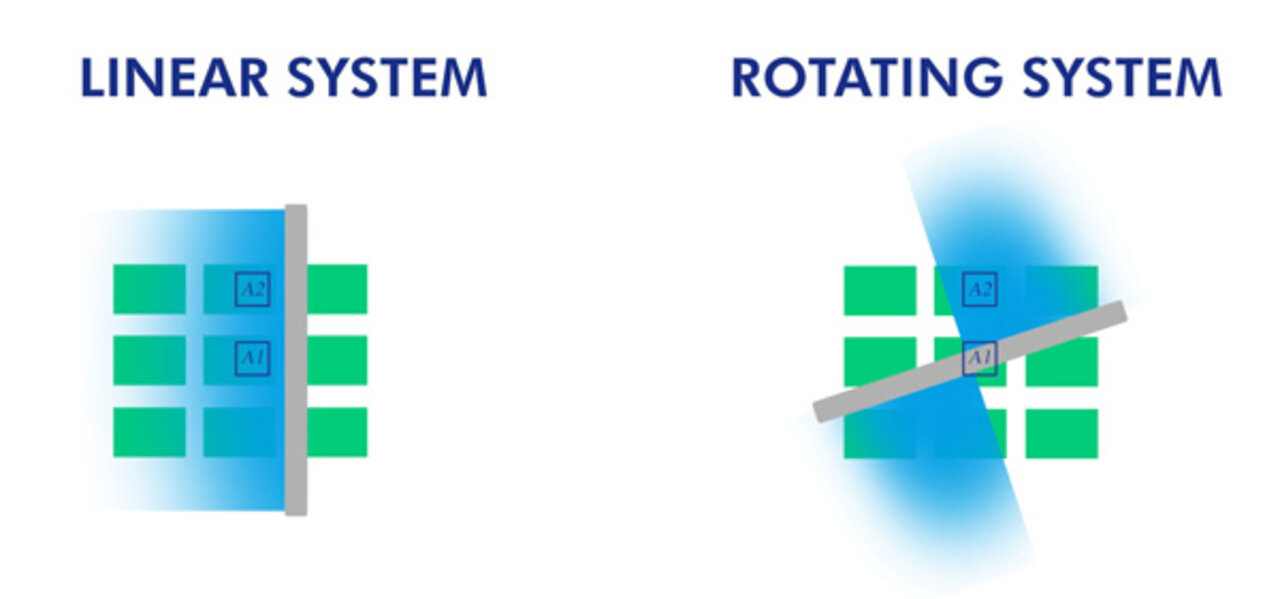

Many machines used for PCB washing processes clean assemblies with moving spray arms. A distinction is made between two types of movement: With linear movement, the spray arm moves evenly in a straight line over the assemblies. With the rotating movement, the spray arm moves in a circle over the boards.

Because of the uniform movement, it is often claimed that only pcb washing processes with linear spray arms would deliver reproducible cleaning results for every assembly in the system. This would make them better than machines with rotating spray arms.

But is this True?

In the video, you will learn about the mathematics behind this assumption, the methods we have used to verify the claim and whether cleaning machines with linear spray arms are really better.

Now, Watch the Fact Check in the Video ▼

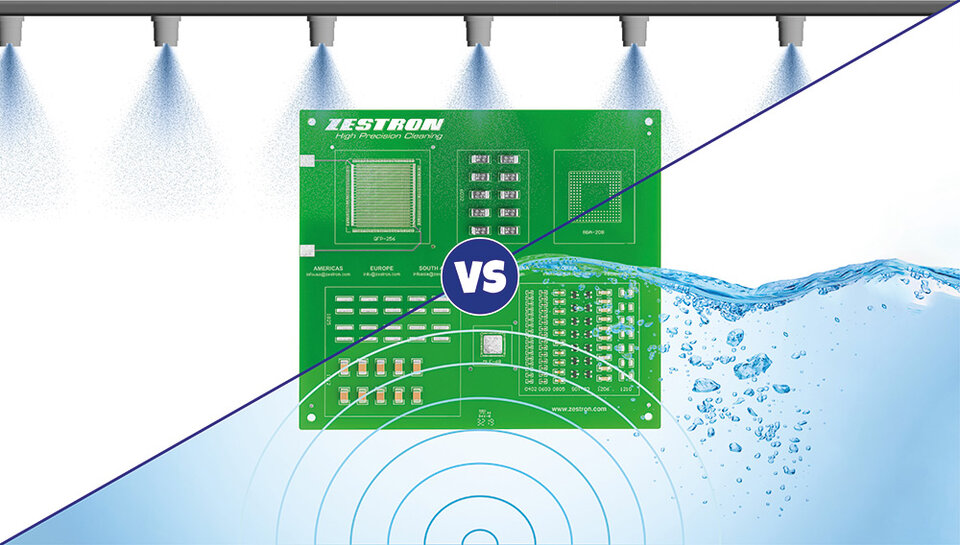

fact check to readPCB Washing Process by Spraying

On the Test Bench: Do Machines with Linear or Rotating Spray Arms Clean Better?

1 | The Basis:

Linear vs. Rotating Spray Arms

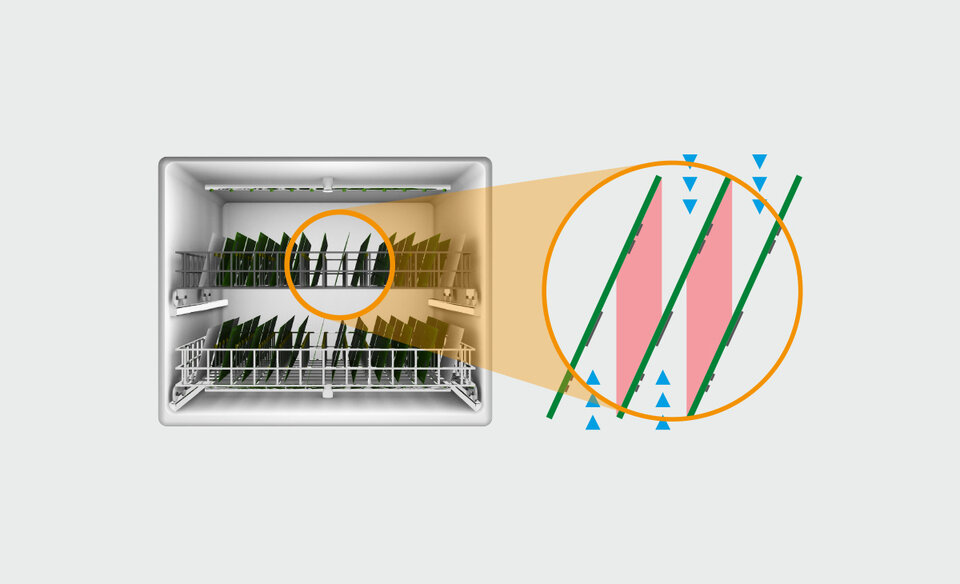

The linear movement of the spray arm suggests that all assemblies receive the same amount of cleaning agent in the same time.

In a machine with rotating arms, the nozzles at the ends of the spray arm rotate around a larger circle than the nozzles in the middle. The larger the circle’s diameter, the larger the area that a nozzle must cover with cleaner. Assuming that the same amount of cleaning agent comes out of each nozzle, assemblies at the outer edge would receive less cleaning agent than assemblies in the centre.

This would mean that when cleaning assemblies under rotating spray arms, the conditions would be different. But under linear spray arms they would be the same – regardless of the assembly’s position in the system.

2 | The Scientific Verification

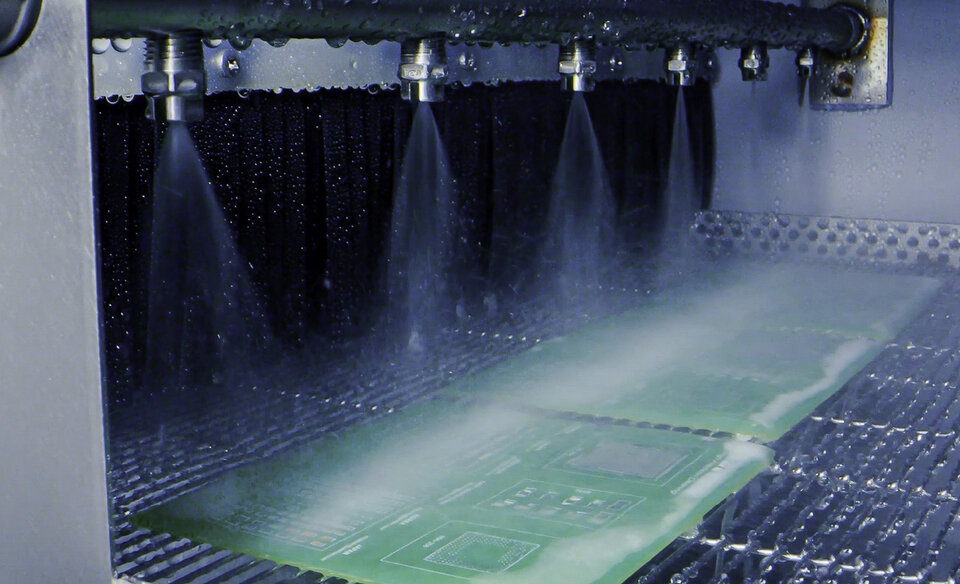

To verify this assumption, we selected two typical machines for assembly cleaning: one with rotating and one with linear spray arms. We carried out the following scientific tests with both machines:

-

Measurement of the amount of cleaning agent:

During the operation of both machines, we measured the amount of cleaner at different positions in the machine. This allowed us to check whether the cleaner is distributed differently with rotating spray arms than with linear spray arms. -

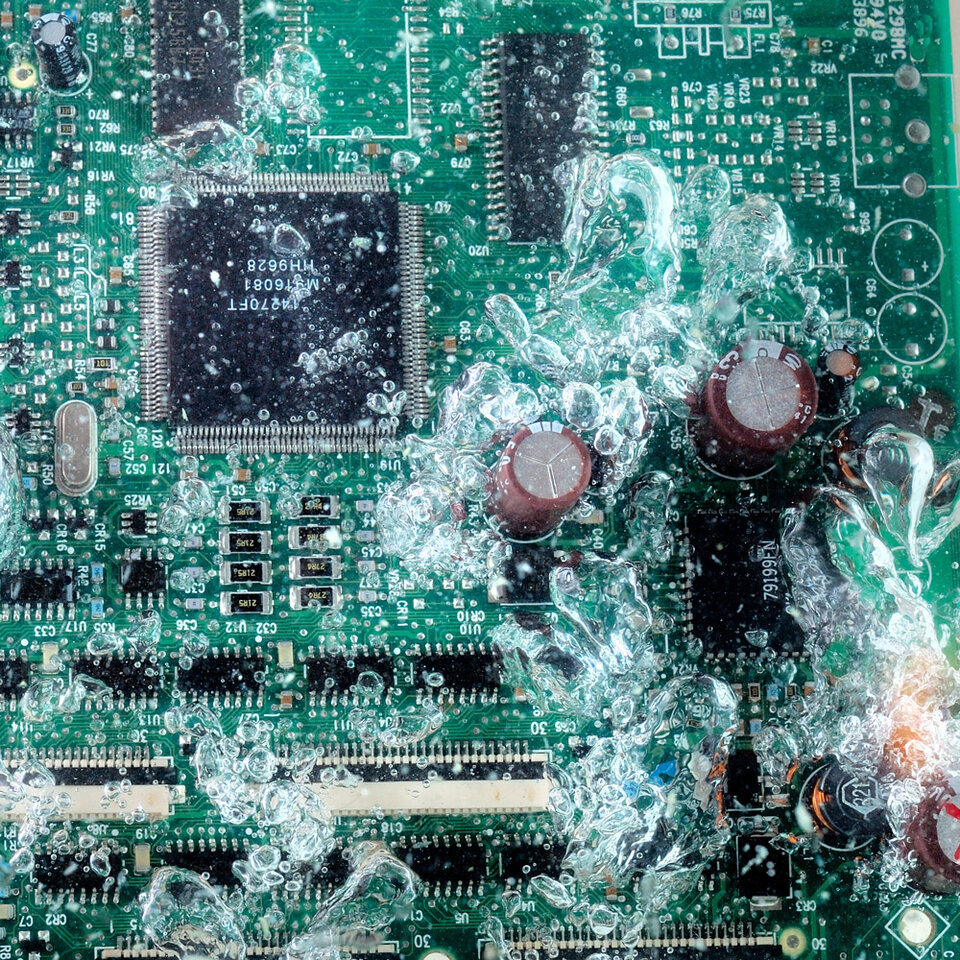

Flux removal under components:To test the cleaning performance on electronic assemblies, we contaminated custom-made, assembled glass test boards with a test flux under the components and cleaned them in both systems. We then examined and compared the flux residues under the components of assemblies at inner and outer positions of the systems.

➞ What are the test results? Are PCB washing processes with rotating or linear spray arms better suited for cleaning assemblies?

Have we Aroused Your Interest?

Ask now for the detailed test results and you will find out which system performed better in the tests and what other factors you should look out for when choosing between systems with rotating and linear spray arms!