Fact check Carriers in PCBA Cleaning – What Matters in Design and Application

time for a fact checkPCBA Cleaning & Carriers

On the test bench: Key Factors in Design & Application.

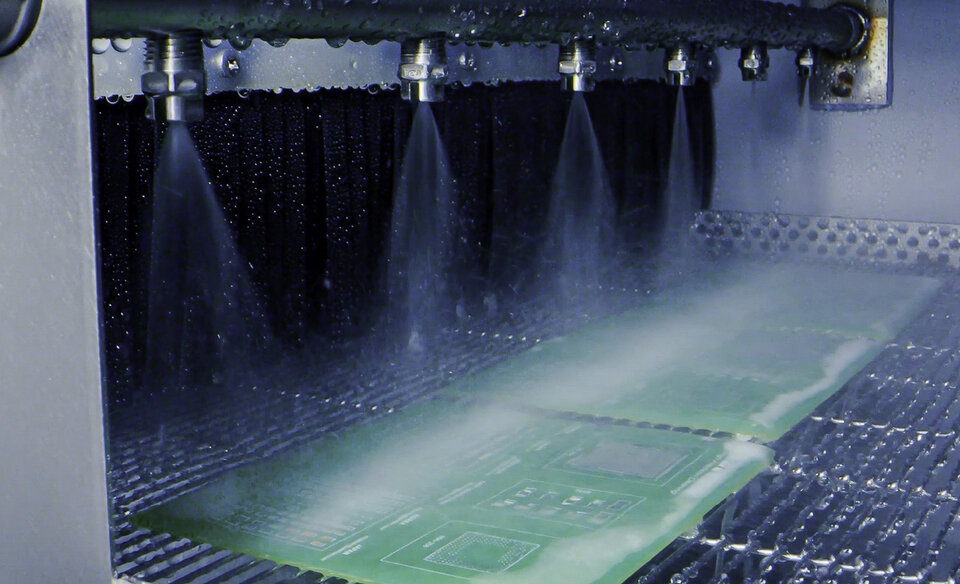

In SMT manufacturing, carriers play a crucial role. They ensure the secure fixation of assemblies during various production steps – whether soldering, coating, or transporting. Carriers are also essential in PCBA cleaning to achieve optimal cleaning results and ensure process reliability.

But what requirements must a carrier meet for PCBA cleaning? And why are specially designed carriers recommended? We've put the key facts to the test.

The fact checkWhy Are Special Carriers Needed for PCBA Cleaning?

On the test bench: Specialized Carriers for PCBA Cleaning

Using a single carrier throughout all process steps would be ideal, but this is often not feasible due to specific material or geometric requirements. While a soldering frame, for example, must withstand high temperatures, a cleaning carrier must be resistant to moisture and cleaning agents. Standard SMT magazines are designed for temporary storage and easy loading/unloading but are usually not suitable for effective cleaning.

So why are specially designed carriers recommended for PCBA cleaning?

Carriers from other production steps quickly reach their limits in PCBA cleaning. Specially designed variants are tailored to optimally support the cleaning process, ensuring uniform and gentle cleaning.

Special Carriers for PCBA Cleaning

Carriers designed specifically for PCBA cleaning offer key advantages:

-

Secure fixation of assemblies during the cleaning process

-

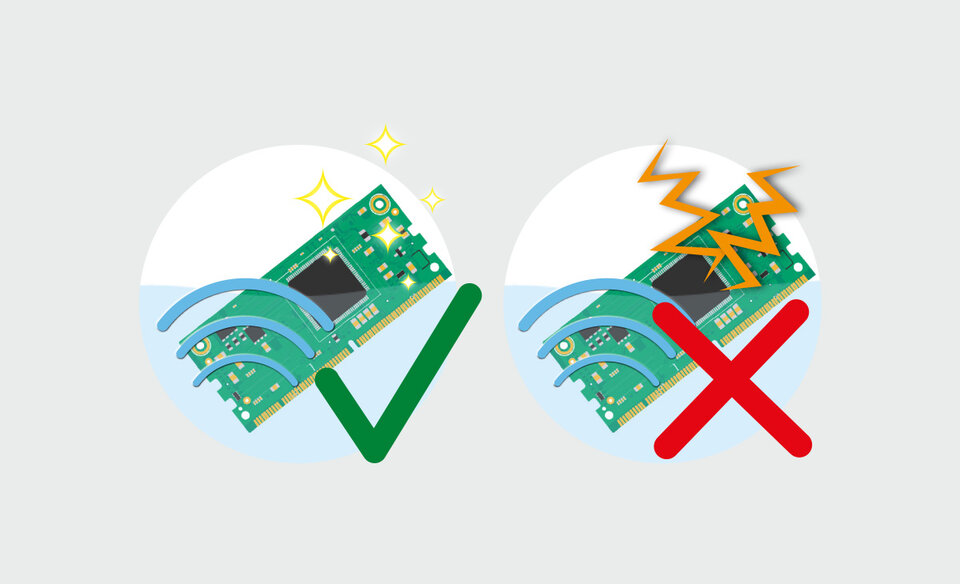

Prevention of damage caused by shifting or collisions

-

Optimal fluid flow to avoid shadowing effects

Types of Carriers in PCBA Cleaning

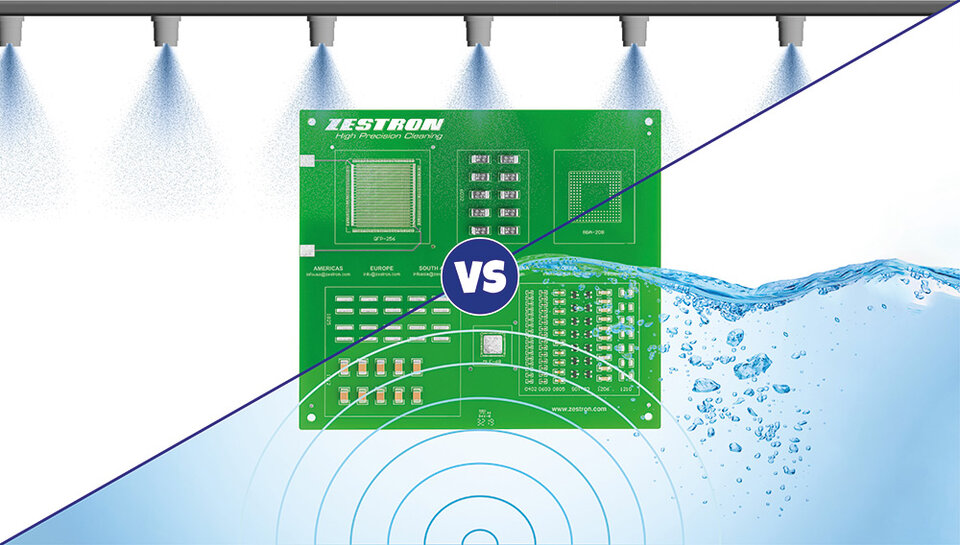

Depending on the cleaning method (immersion, spray) and system type (batch or inline system), different carrier systems are used:

Open Basket

-

Assemblies are loosely placed between spacers or fixed in place

-

Comparable to a dishwasher basket

-

Suitable for batch and ultrasonic cleaning systems

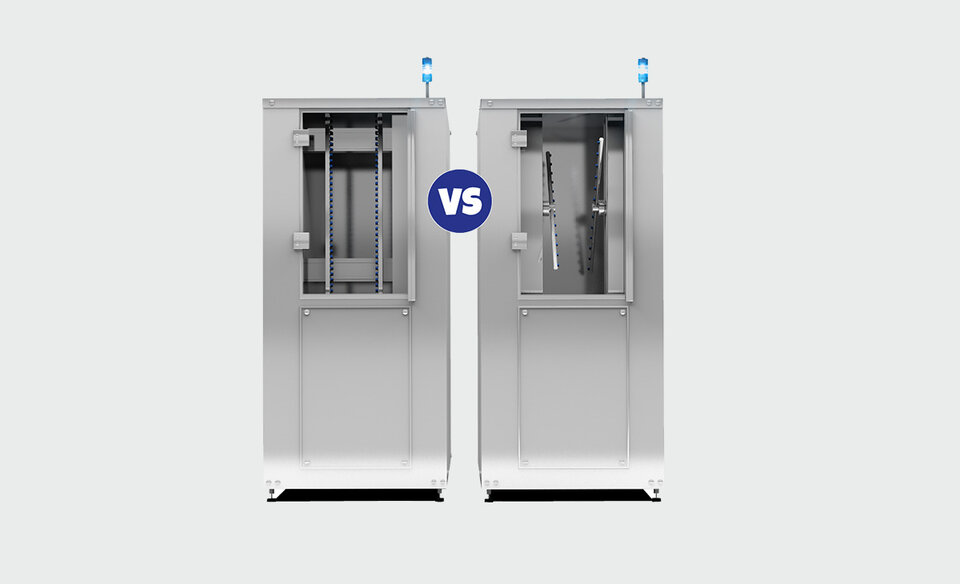

Closed Basket

- Mainly used in inline spray cleaning systems to ensure secure handling on the conveyor belt

Wash Frame

- Frame with holders where assemblies are clamped in place

Additional Systems

-

Custom solutions, e.g., for cleaning directly within SMT magazines

-

Specially tailored designs for specific requirements

PCBA Cleaning: Selecting the Right Carrier

Choosing the right carrier for PCBA cleaning depends not only on the cleaning system and what the equipment manufacturer offers but also on the characteristics of the assemblies being cleaned. Geometry, size, and shape are critical factors.

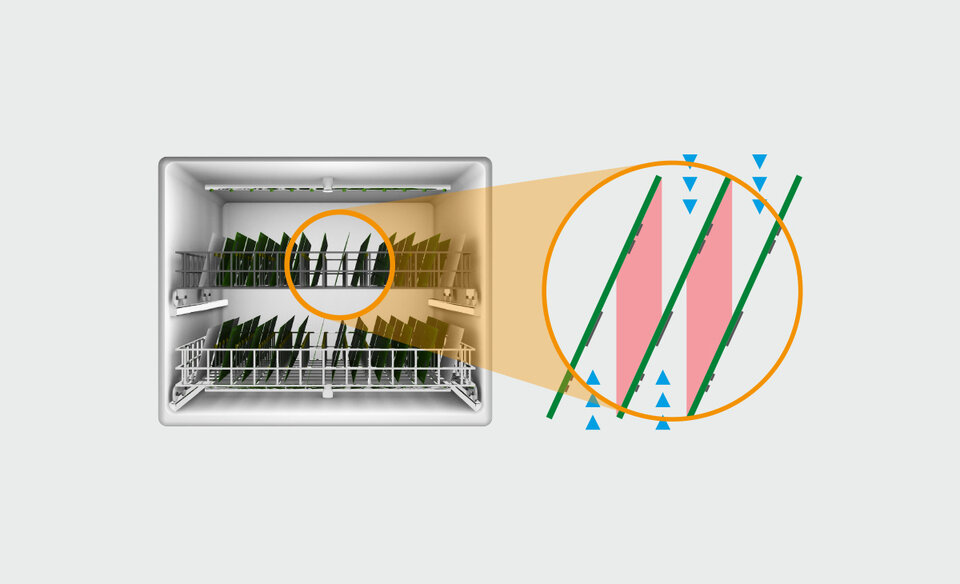

Additionally, the carrier system significantly affects both the cleaning process and final results. Proper placement of assemblies within the basket and the overall packing density are crucial to avoid shadowing effects. Even the carrier itself can obstruct parts of the components being cleaned.

Depending on the cleaning system and carrier type, various levels of automation are possible: from automated basket loading to full integration into the production line.

Selecting the ideal carrier for your PCBA cleaning process depends on several key factors. To help you make the right choice, we have conducted a fact check and analysed different carrier types.

Request your information now and benefit from:

-

A comprehensive overview of different carrier systems

-

Expert recommendations on which carrier type suits your assemblies best

-

Practical tips for carrier selection and design

-

Exclusive test results: How effective is cleaning when assemblies are processed directly in the magazine?