InsightsFlux Residues and Their Effects on Electronic Assemblies

What risks do flux residues pose to electronic assemblies? If left unaddressed, they can cause corrosion, malfunctions and failures — but effective removal prevents them.

flux residuesWhy Flux Residues Must Be Removed from Electronic Assemblies?

The presence of flux residues on assemblies can have serious consequences as they can impair the performance of control units and lead to issues such as corrosion, electrical malfunctions, or even total failures. In industries such as automotive, electromobility, renewable energy, communications, or medical technology, where reliability and durability are crucial, it is of utmost importance to carefully remove flux residues.

the problem How are Flux Residues Formed?

Flux residues are formed when flux is not completely vaporized during the soldering process. Depending on the type of flux used, the residues can have different properties. They are generally categorized as water-soluble and non-water-soluble, both of which can be corrosive.

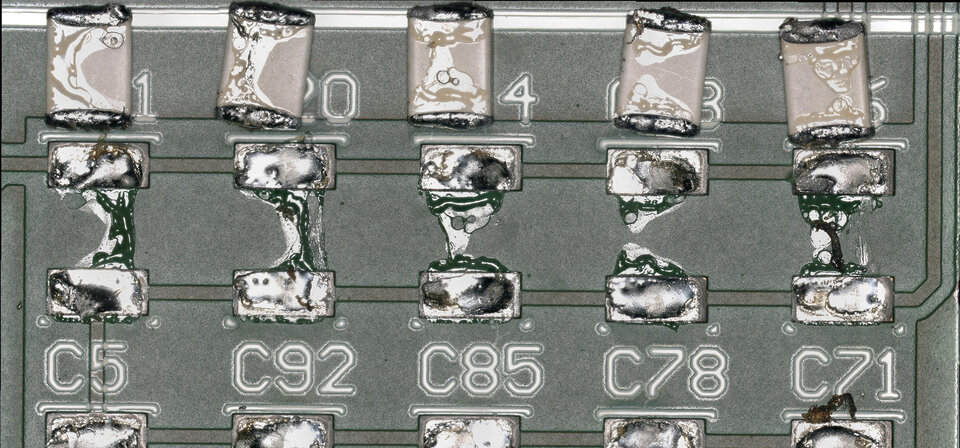

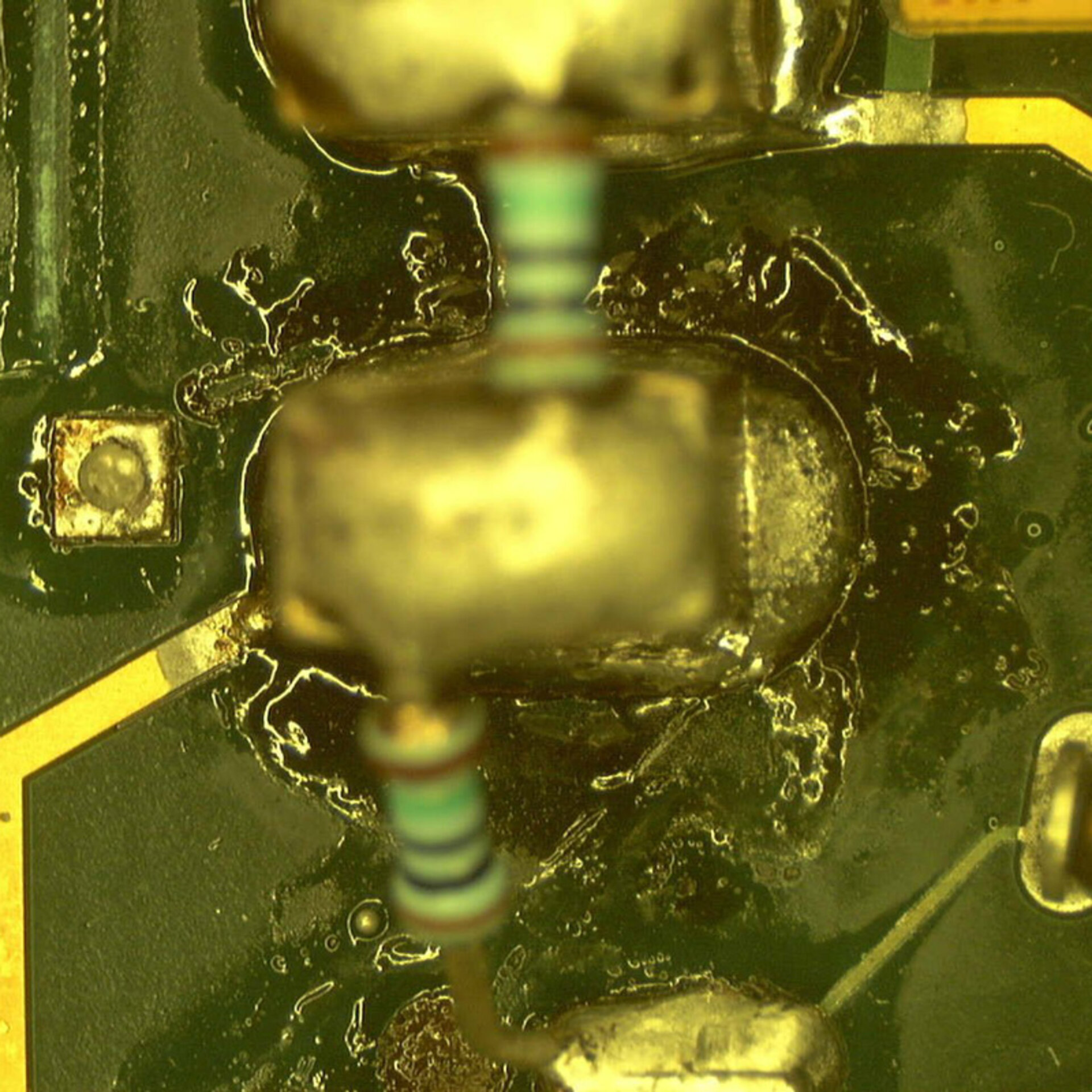

These flux residues remain on the surfaces of assemblies after the soldering process and can manifest as thin or thick layers, lumps, or sticky substances.

The formation of flux residues can be influenced by various factors such as the type of flux used, soldering technique, temperature and duration of the soldering process, as well as the cleanliness of the components and the soldering environment.

the impactProblematic Effects of Flux Residues on Assemblies

It is evident to everyone that flux residues are not beneficial for electronic circuits. But what exactly can these residues cause if left unattended?

![]() Electrical Problems:

Electrical Problems:

Flux residues can cause electrical disturbances, especially if they are conductive. They can lead to short circuits, leakage currents, or other malfunctions that affect the performance of the assembly.

![]() Reliability:

Reliability:

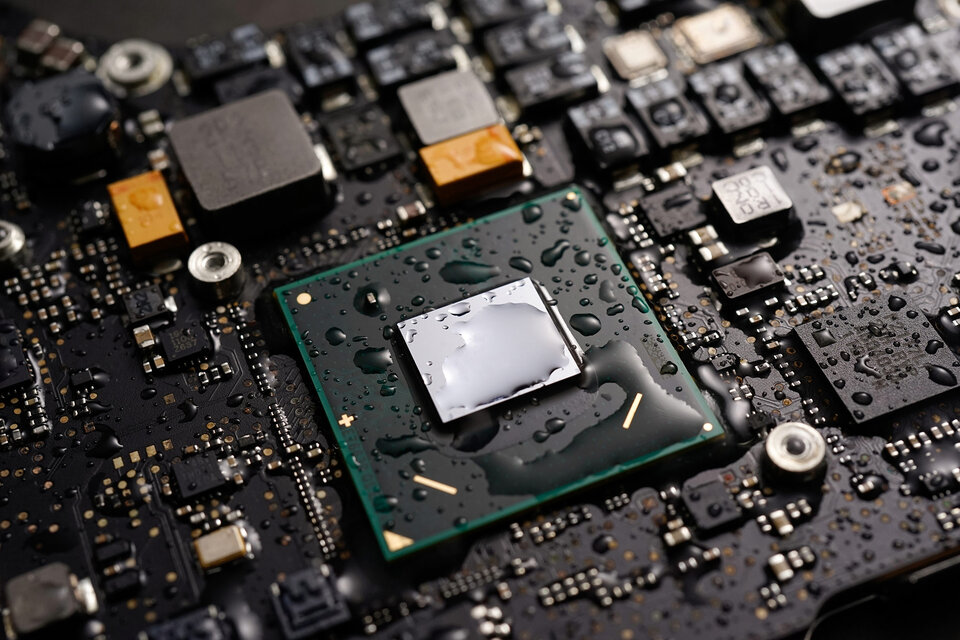

Flux residues can impair the reliability of the assembly. Over time, the residues can absorb moisture, leading to corrosion, oxidation, and other harmful effects.

![]() Corrosion:

Corrosion:

Some fluxes contain aggressive chemicals that can cause corrosion on assembly surfaces. This can result in deteriorated solder joints, metallization, or other components, ultimately reducing the lifespan of the assembly.

![]() Insulation Issues:

Insulation Issues:

If flux residues are present on insulating surfaces such as plastic or ceramic, they can compromise the insulating properties. This can lead to leakage currents, electrical breakdowns, or other insulation problems.

The exact effects depend on the composition of the flux, the amount of residues, the duration of exposure, and other factors.

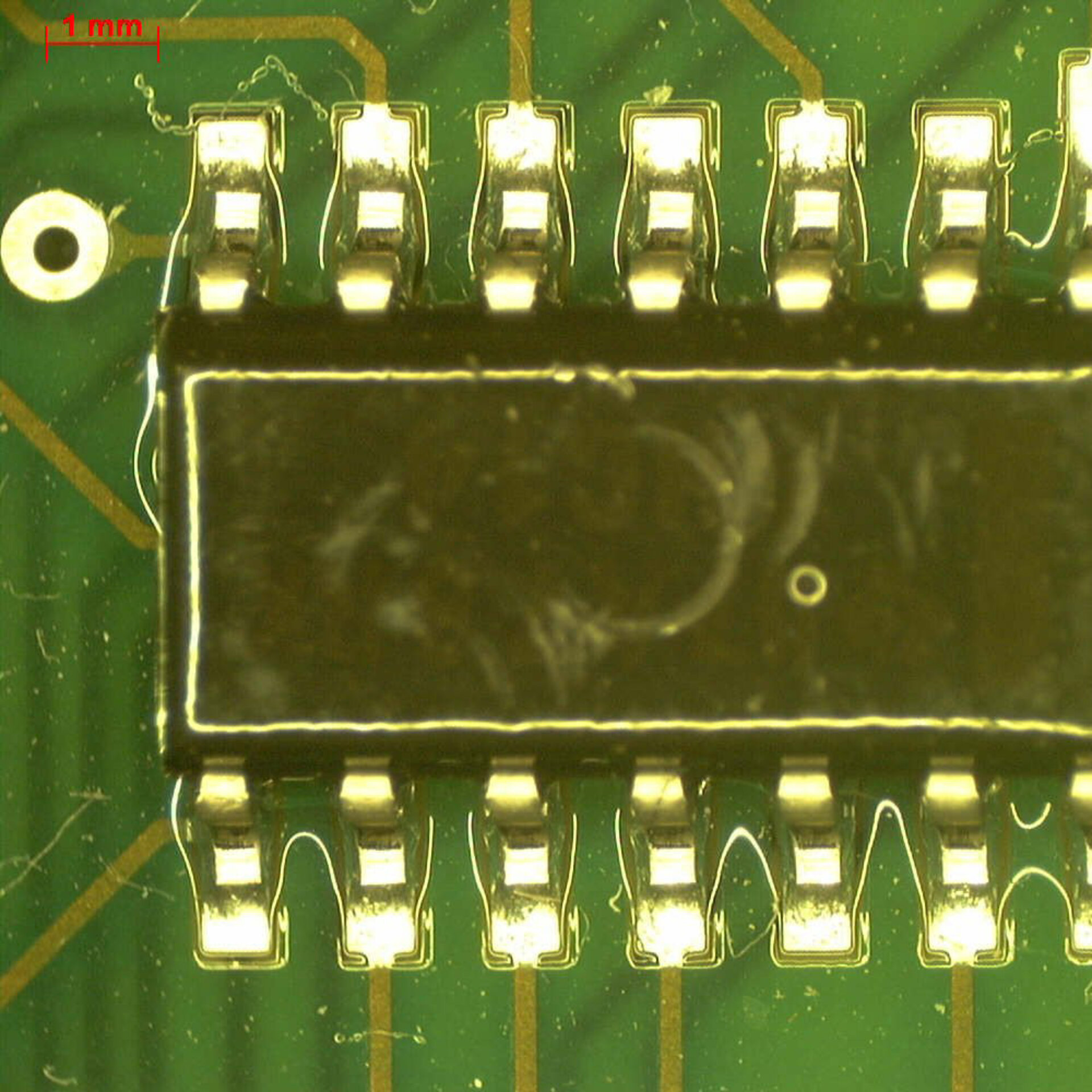

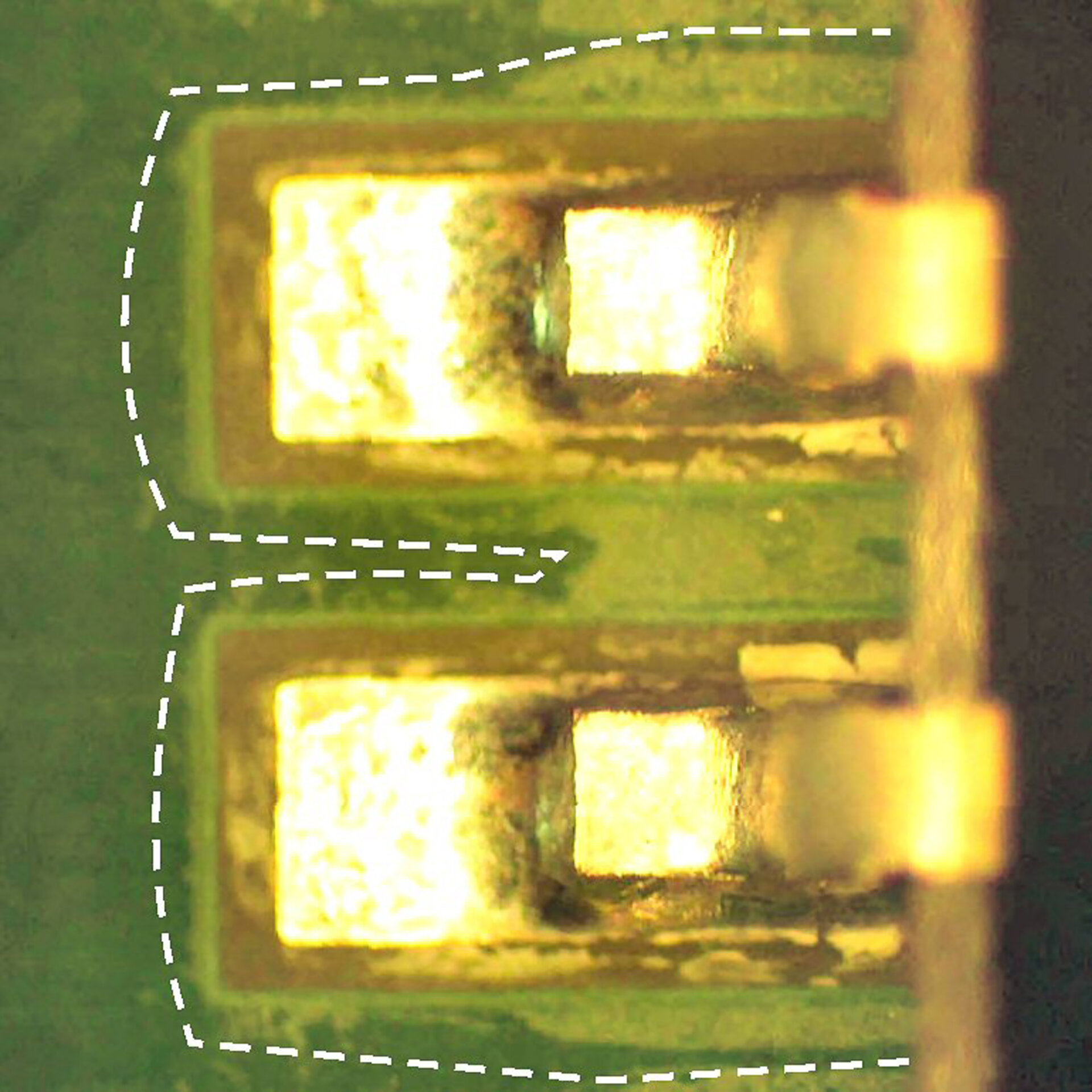

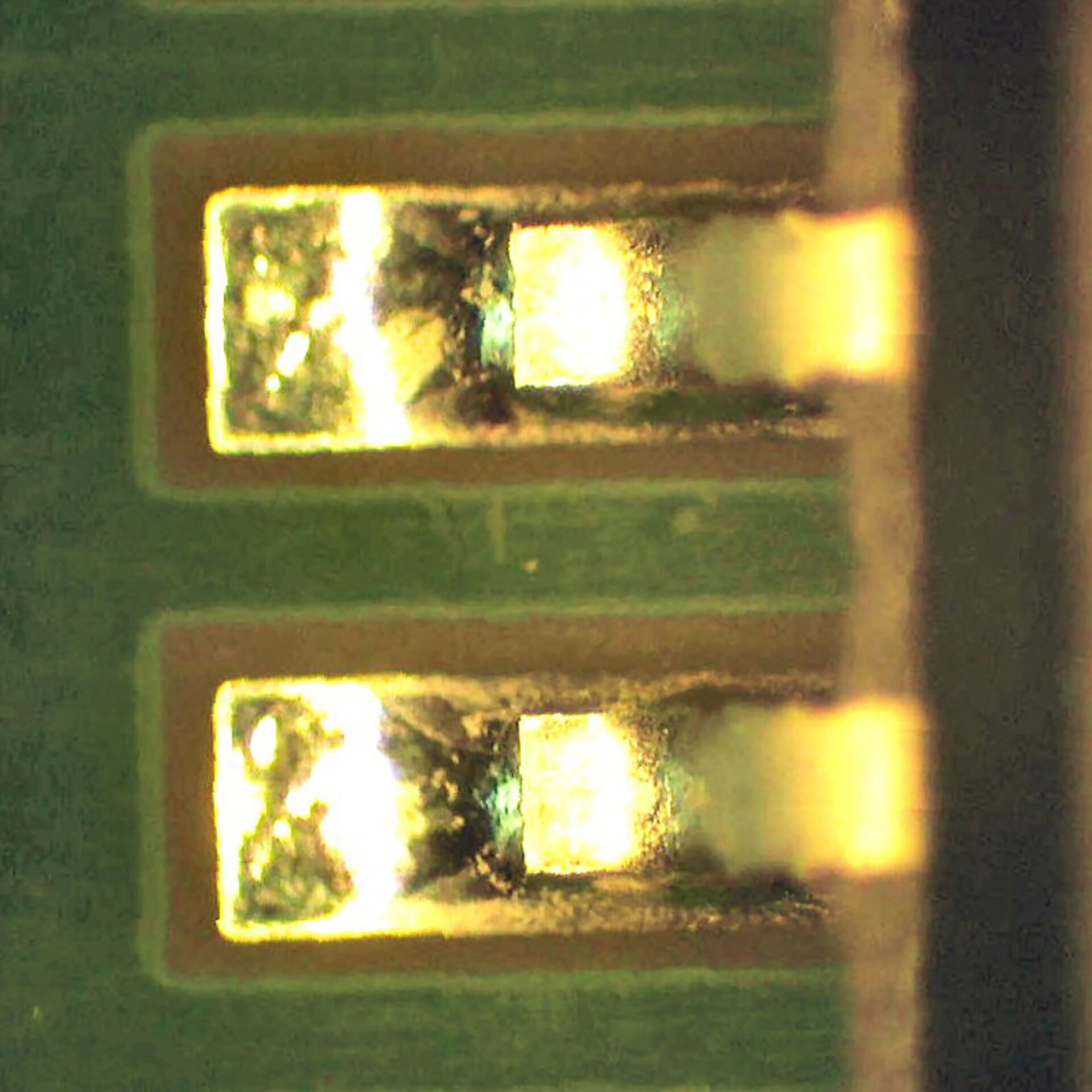

In today's time, the miniaturization of assemblies plays a significant role and poses challenges for developers. It becomes particularly dangerous when the paths between solder joints become increasingly smaller, and flux creates a bridge, causing a short circuit.

The SolutionMinimizing Risks Through Cleaning

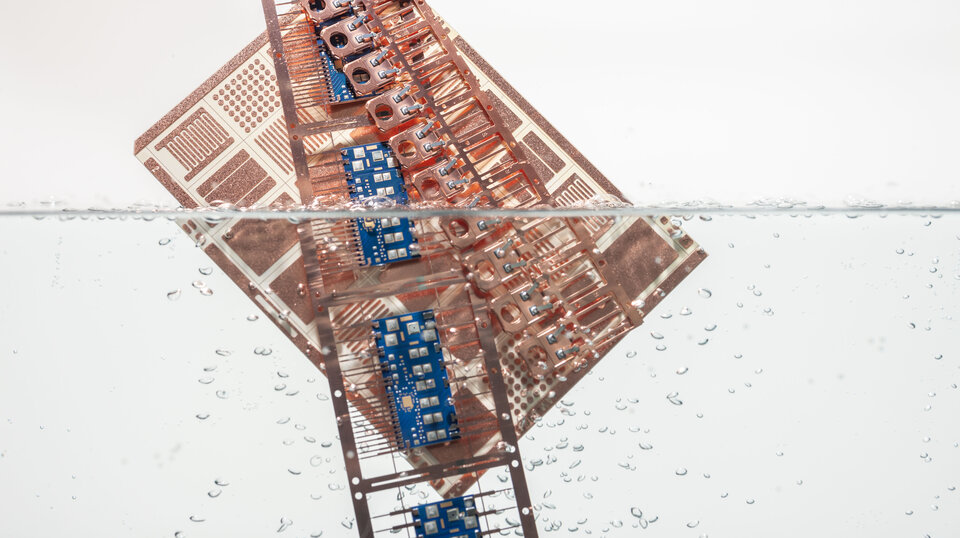

To safely remove all flux residues from the printed circuit boards and thereby minimize the risks of errors and failures, thorough cleaning is crucial. The clean PCBs are then optimally prepared for subsequent processes such as soldering, molding, or bonding.

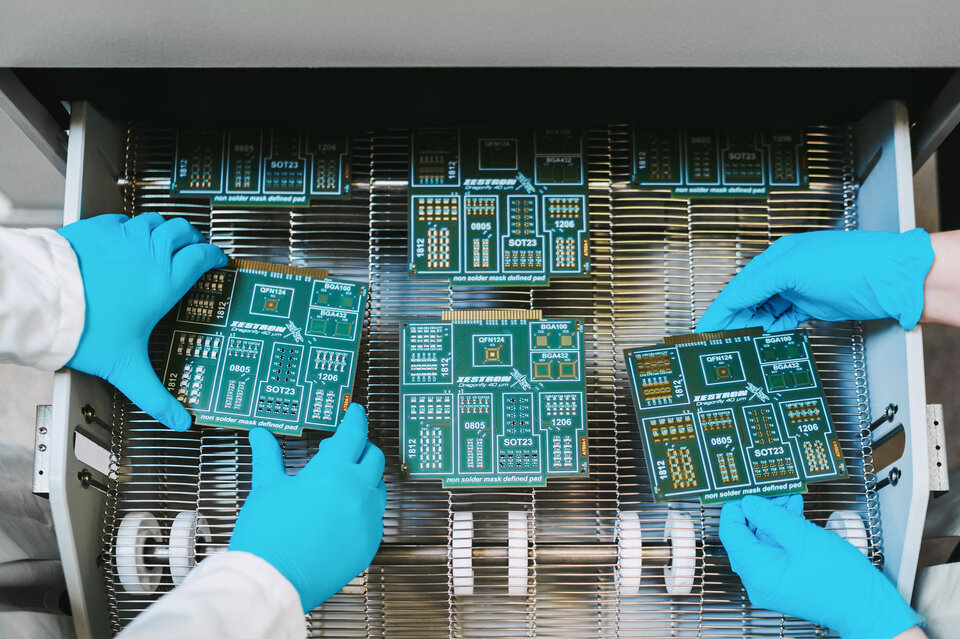

ZESTRON offers a wide range of cleaning agents specifically designed for the removal of flux residues without damaging the assemblies or their components. We are ready to assist you in tailoring your cleaner to your existing flux residues and provide individual advice to make the cleaning process efficient and cost-effective.

STEP by STEP - Flux Removal from Electronic Assemblies

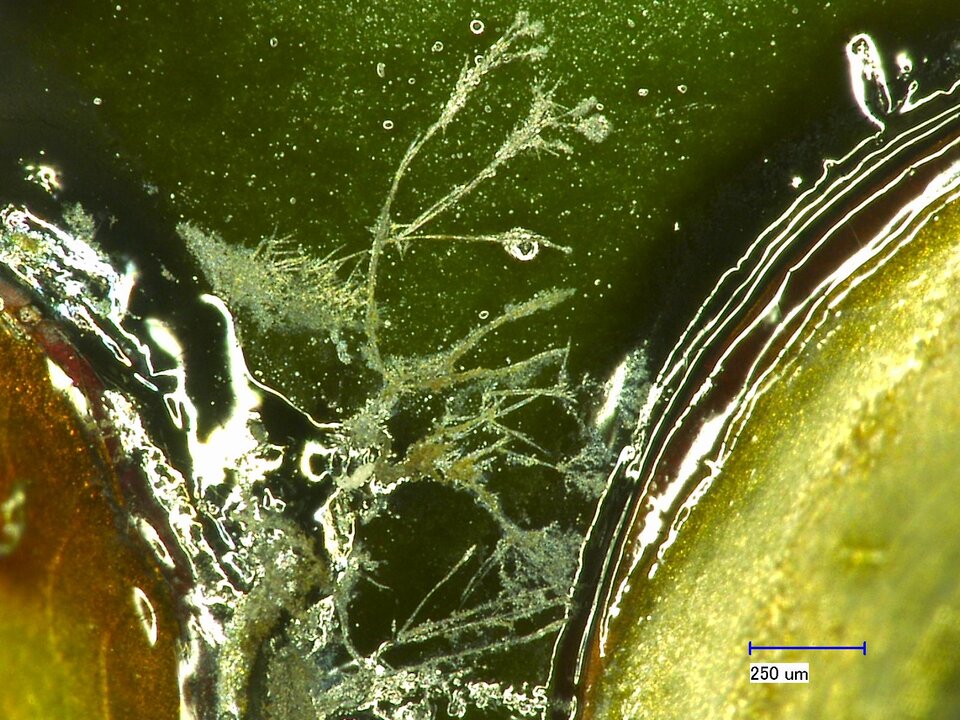

process optimizationHow to Detect Flux Activators on Electronic Assemblies

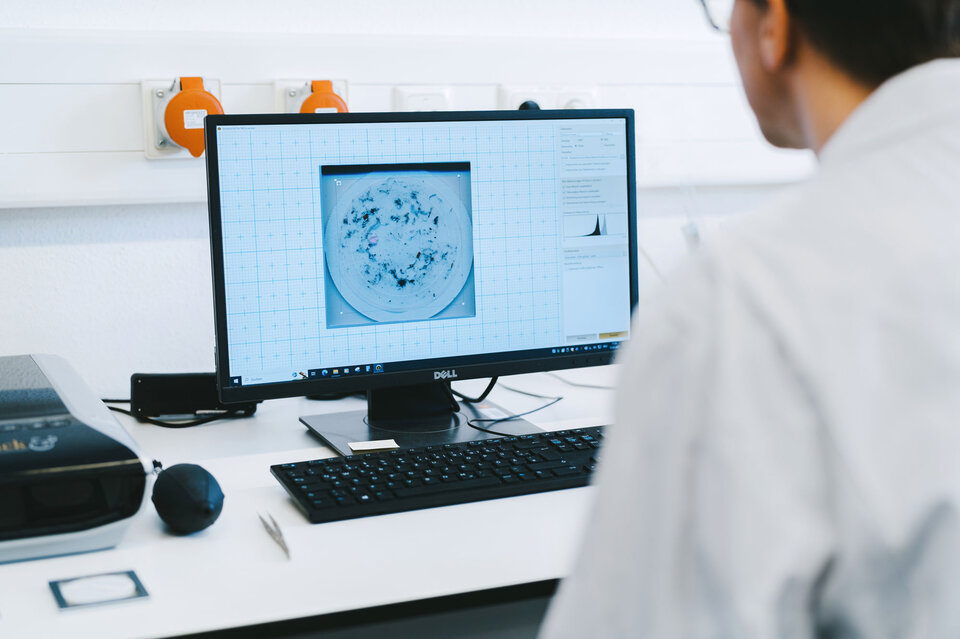

The ZESTRON® Flux Test visually detects the activators of fluxes through a color reaction. The test complements the ionic equivalent by also making critical flux residues visible that are not detectable in water-alcohol mixtures. Thus, it provides insights into the local distribution of contaminants and enables an improved assessment of the reliability of assemblies.