InsightsEnsuring Maximum Technical Cleanliness for Your Electronic Assemblies

Tracking particulate contaminants on electronic assemblies through damage analysis and risk assessment to ensure surface cleanliness

analytical servicesFailure Analysis and Risk Assessment: Ensuring Maximum Technical Cleanliness

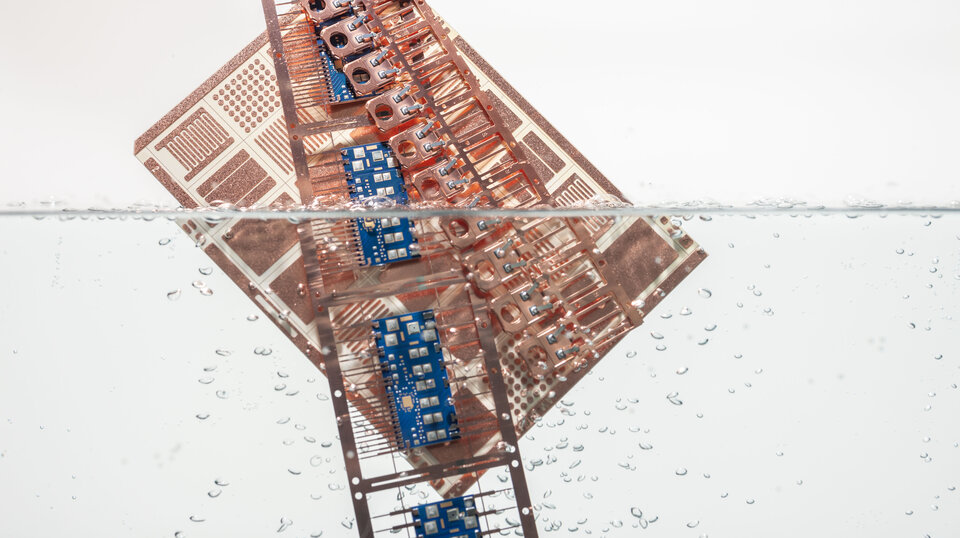

Particulate contamination can lead to various malfunctions in assemblies and systems, such as short circuits, electrical isolation at contacts, and reduced solderability. To ensure that your assemblies function flawlessly and meet the highest PCB surface cleanliness standards, precise limits are essential in supplier specifications. To efficiently and practically specify these limits, we recommend a thorough risk assessment of the particles and their potential impacts. If a malfunction has already occurred, we are also available to provide extensive damage analysis.

Typical Malfunctions Caused by Particle Contamination

Even the smallest particles on printed circuit boards can lead to serious malfunctions – from unreliable contacts to complete system failures. Below are concrete examples of damage caused by particulate contamination:

![]() Short Circuits

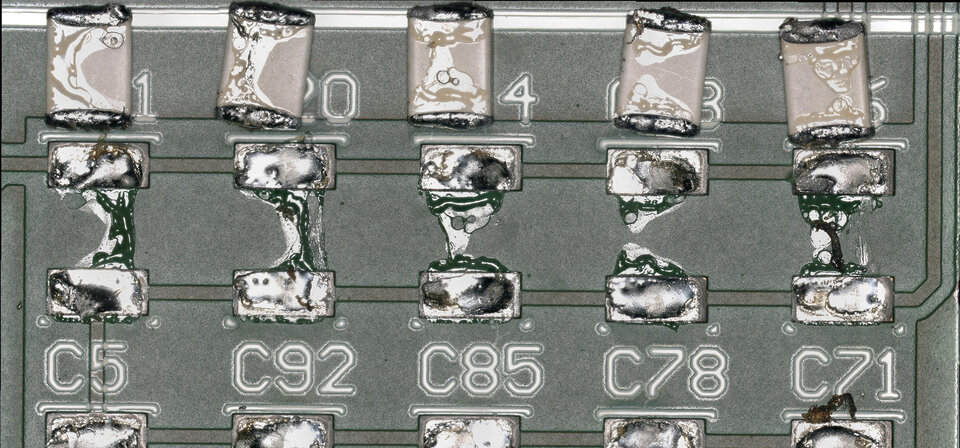

Short Circuits

When particles accumulate between two electrical traces or components, short circuits can occur. This can result in malfunctions or even failure of the assembly.

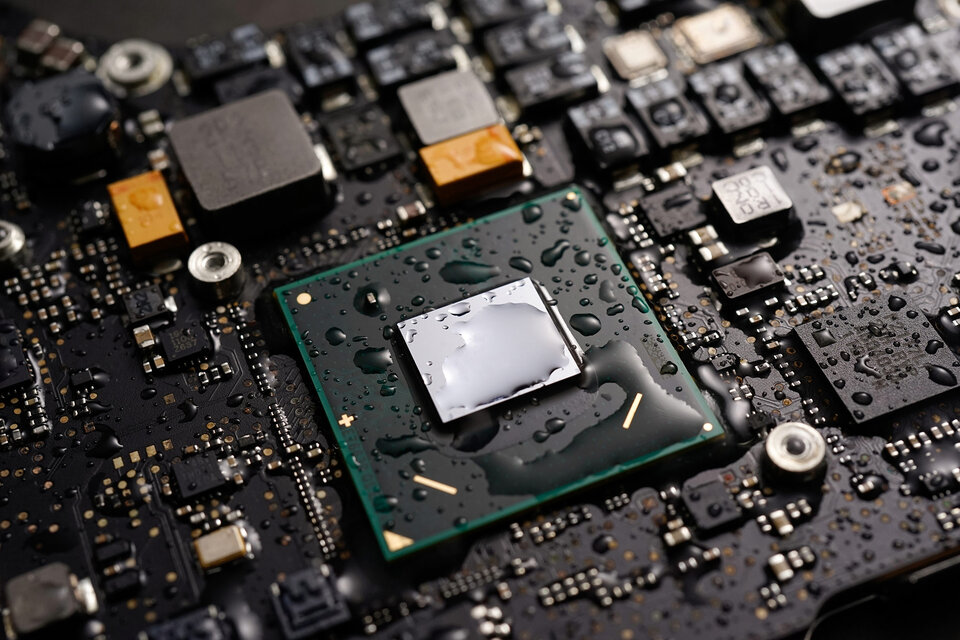

![]() Insulation Failure

Insulation Failure

Contaminants can compromise the insulating properties of the materials on the circuit boards. This can lead to leakage currents or insulation failure, affecting the electrical integrity of the assembly.

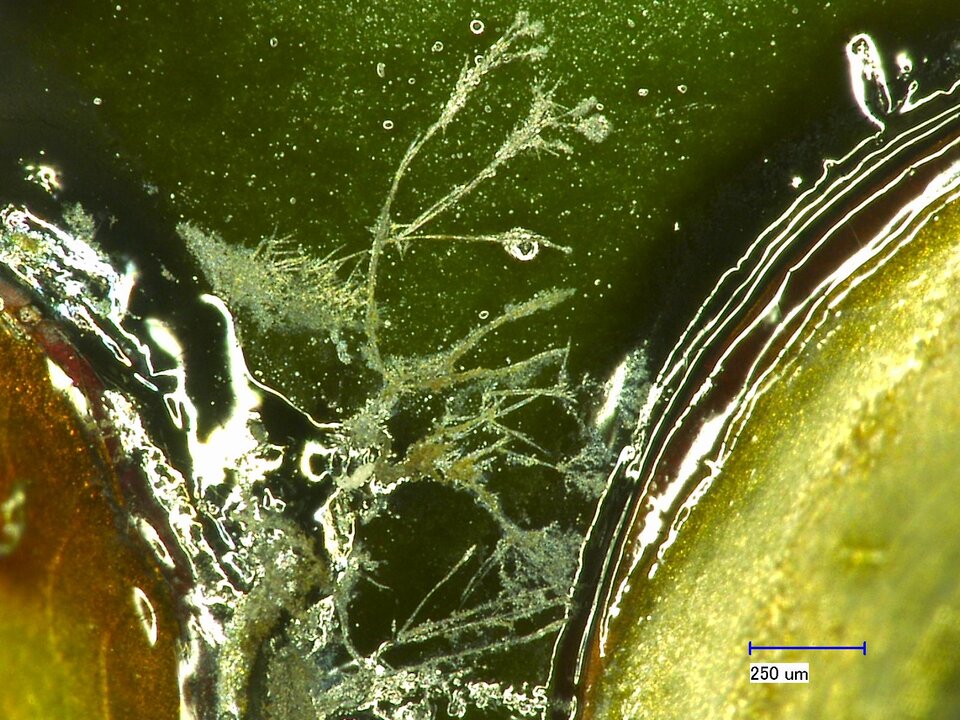

![]() Oxidation and Corrosion

Oxidation and Corrosion

Particles containing corrosive substances can cause oxidation and corrosion of the traces and components. This can impair electrical conductivity and lead to poor signal quality or functional failures.

![]() Mechanical Stresses

Mechanical Stresses

Larger particles or foreign objects can subject the circuit boards to mechanical stresses. This can cause cracks, fractures, or delamination, compromising the structural integrity and damaging the assembly.

Risk AnalysisDetermining the Risk of Failures Caused by Particles

Preventing failures before they occur.

Our comprehensive analysis methods are based on the standards of the VDA 19 guideline, ZVEI guide, and IEC TR 61191 standard. We identify potential malfunctions early on and provide a detailed risk assessment of particle loads.

Through joint audits, high-quality analysis equipment, and interpretation of results, we help you understand, evaluate, and prevent risks and malfunctions. Our tailored solutions support you throughout the entire manufacturing process to meet your specific requirements for technical cleanliness and PCB surface cleanliness.

Analysis Methods

-

Wetting Current Analysis

Determining the breakdown voltage and conductivity properties of particles -

Impedance Spectroscopy

Determining the hygroscopy of particles and

estimating the impedance properties -

Fourier Transform Infrared Spectroscopy (FTIR) Determining the particle composition

-

Scanning Electron Microscope (SEM/EDX)

Determining the degree of oxidation and the particle composition

Damage Analysis Identifying and Remedying Failure Causes Due to Particles

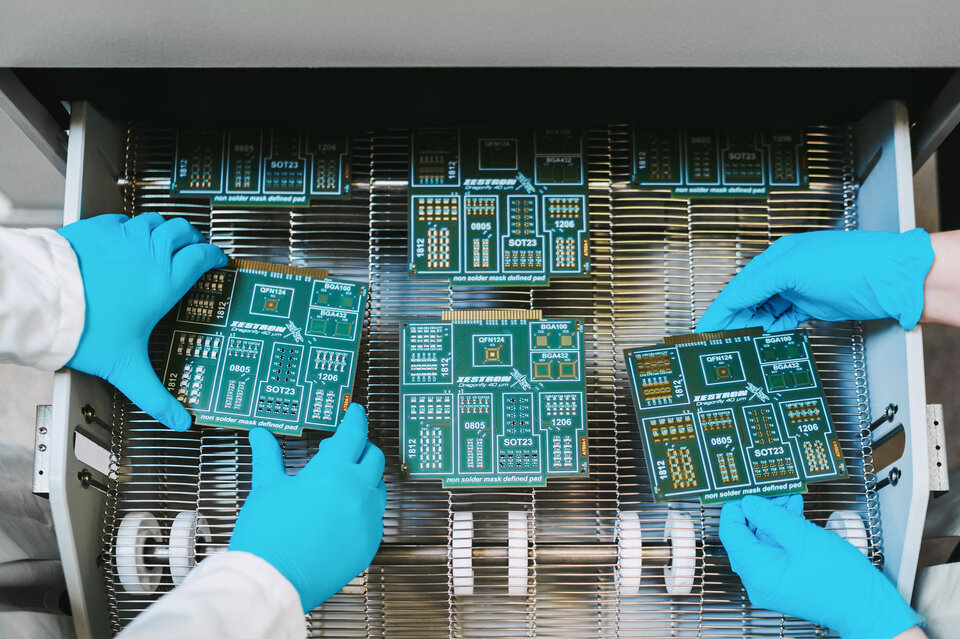

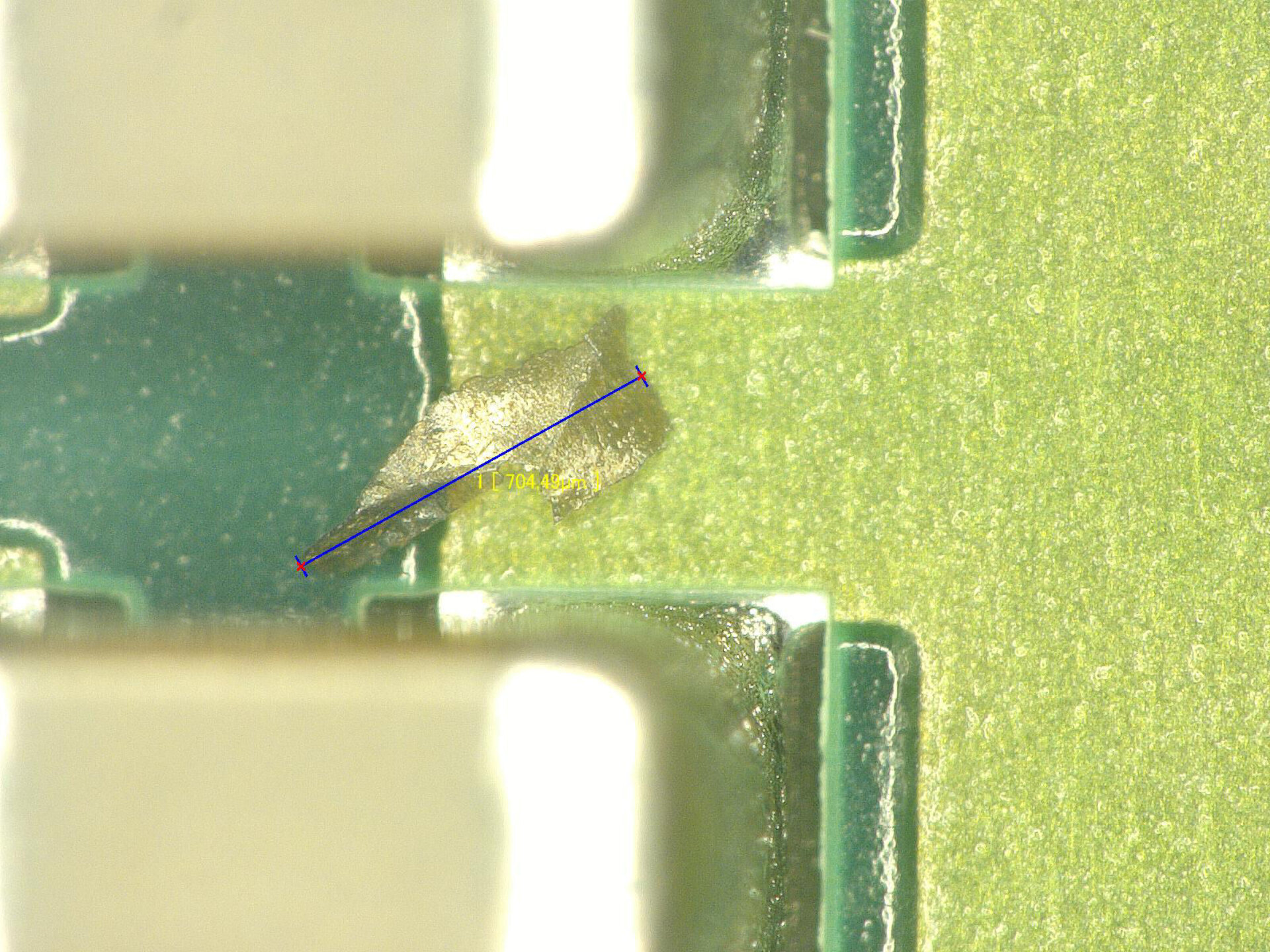

We conduct a comprehensive analysis of the damage caused by particulate contamination according to the VDA19 and ISO 16232 standards. By extracting and analyzing the type and size distribution of particles, we provide you with detailed solutions to address the problem and improve component safety.

Our goal is to provide precise recommendations based on the analysis results, minimizing the failure risk of your electronic assemblies.

Particle Measurement / Technical Cleanliness

-

Qualitative and quantitative measurement of particles by type and size distribution

-

Comparison with requirements according to the ZVEI guideline for component cleanliness

-

Evaluation of influence on the cause of damage

-

Basis for risk assessment of particles with SIR (Surface Insulation Resistance)

-

ISO 16232

technical cleanliness - focus on particle contaminationOur Expertise

-

Years of experience in risk assessment of particles and damage analysis caused by particulate contamination

-

More than 100 Tier-1 suppliers rely on our expertise

-

Involvement in the ZVEI component cleanliness research group and collaboration on the “Technical Cleanliness in Electrical Engineering” guideline

-

Collaboration on international standardisation

Your Benefit

-

Analytics and system discussions - tailored to your needs

-

Close communication from first contact to solution recommendations

-

Action recommendations in the context of the system

assitance moduleTechnical Cleanliness

Our assitance module on technical cleanliness on electronic assemblies provides an overview of potential risks, practical examples, intensive learning in a small group, and the opportunity to exchange with an experienced instructor.

zestron whitepaper collectionTechncial Cleanliness in Electronics Manufacturing

Revised New Edition 2024

Discover the risk of particle contamination in the electronics industry and effective cleaning methods. Request now to meet customers’ expectations and reduce particle loads!