InsightsThe Long-Term Benefits of Power Electronics Cleaning

DCB-Cleaning: Enhance the performance and lifespan of your systems by taking the crucial step of cleaning your power modules.

Power modulesProcess Reliability for Power Modules Starts at the Surface

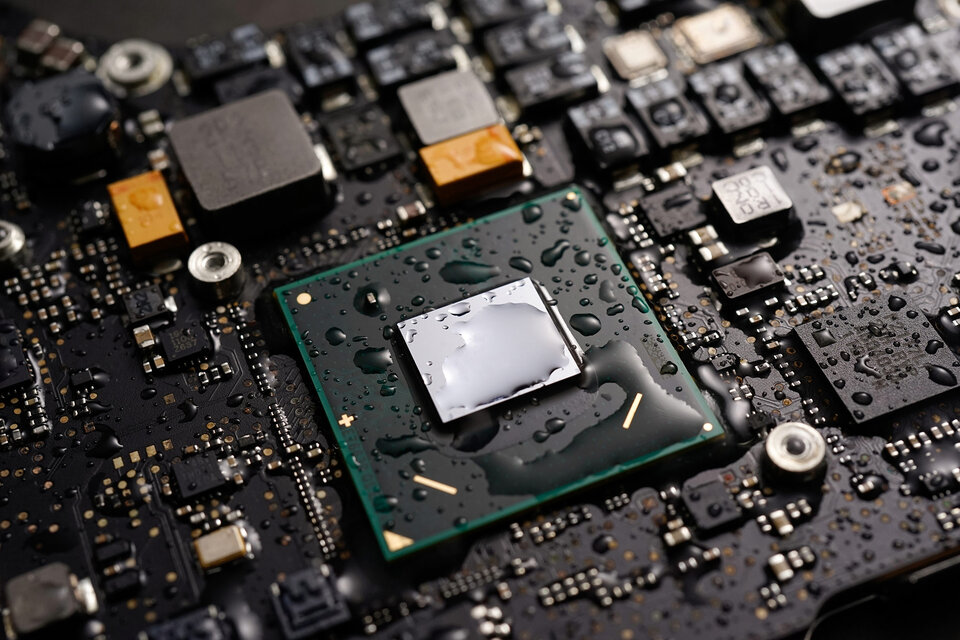

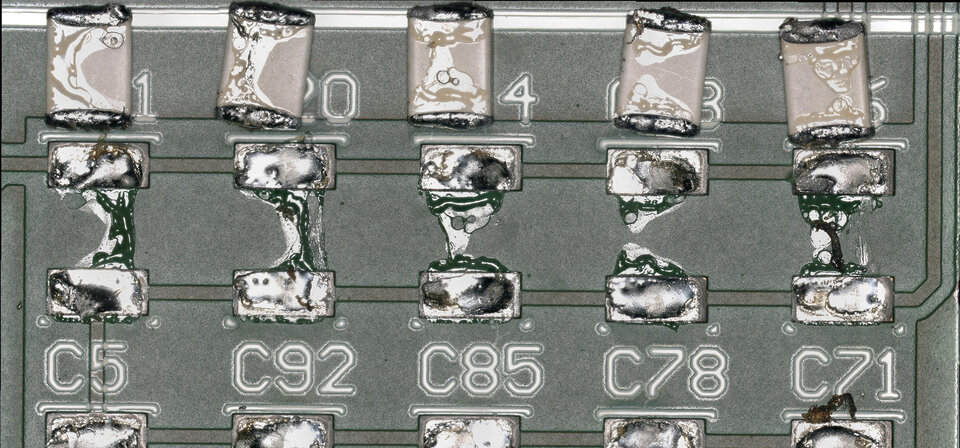

Power electronics place high demands on reliability, thermal management, and process stability. Contaminants on substrates can impair electrical performance and lead to undesirable effects in subsequent processes. Targeted cleaning can provide the foundation for robust connections and consistently high product quality.

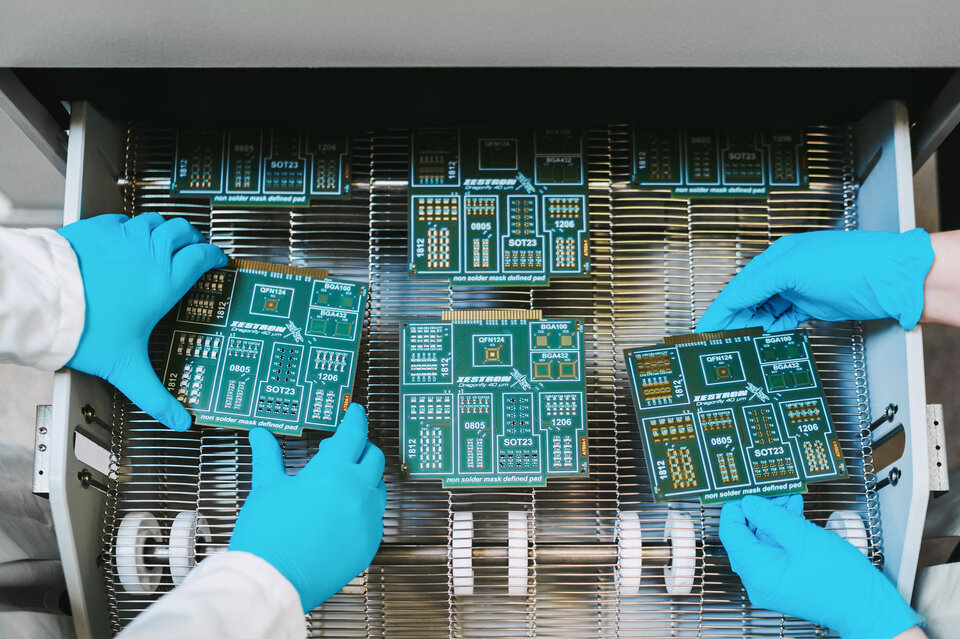

POWER ELECTRONICSCleaning of Power Modules

The cleaning of (IGBT) modules in power electronics or so-called DCBs is an absolute must. On the one hand, after die attach to prepare the substrate surfaces of the modules for wire bonding. On the other hand, after soldering the substrates onto the heat sink, the so-called "heat sink soldering".

CLEANING PROCESSMain Requirements for the Cleaning Process

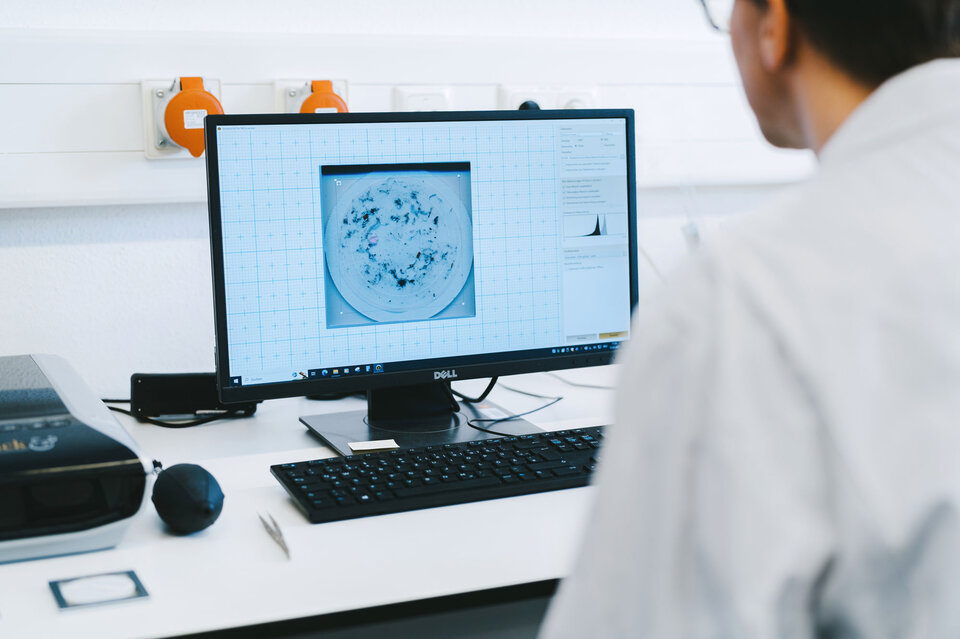

In order to actually achieve improved results - for example in shear tests or qualification by power cycling - and also to ensure an increase in production yield, two main requirements are necessary:

-

A complete removal of flux residues on the substrates, especially flux splashes.

-

A complete, optical removal of stains or oxide layers from the substrate and chip surfaces.

Through specially developed processes with aqueous cleaning media, ZESTRON offers the possibility to generate high-purity surfaces and thus significantly increase the wire bond quality.

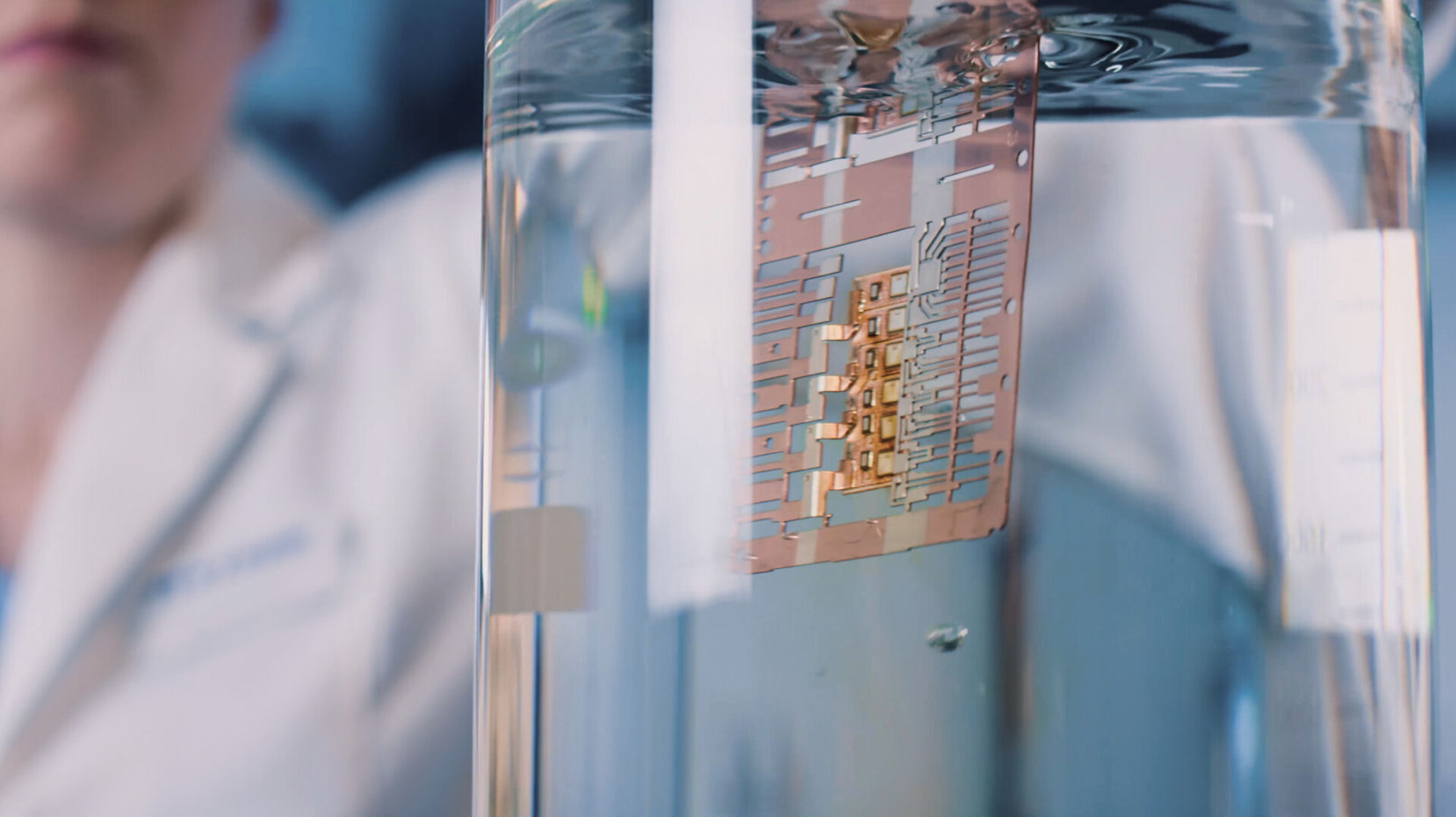

leadframes Cleaning of Leadframe-Based Discrete Devices

In this case, MOSFETs, IGBTs and SOTs are soldered onto the base substrate or leadframe with solder paste in the so-called die-attach process.

Due to the occurrence of high peak temperatures during the soldering process, the associated demands on the cleaning process also increase:

-

Complete removal of the flux from the soldering process

-

Removal of all inorganic stains and activation of the (copper) surfaces

-

Material compatibility of the cleaner with all materials

Power-LEDsCleaning of Power LEDs

Here, too, ZESTRON offers excellent cleaning performance for substrate and chip surfaces with water- and solvent-based cleaning media, thus ensuring increased bond quality, better results in tensile and shear tests, and optimum adhesion of the moulding.

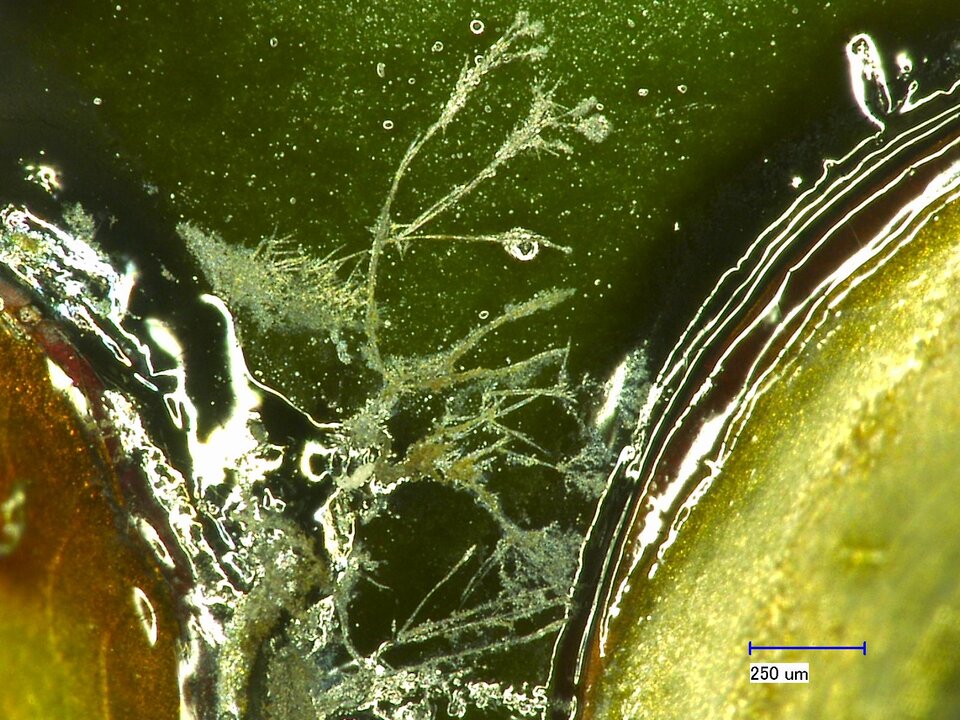

In power LED production, too, it is essential to clean after the die attach. If the flux residues are not removed, this would lead to poor conditions during wire bonding and consequently to bond fractures or even chip defects.

A cleaning process adapted to power LEDs with water-based cleaners or modern solvents from ZESTRON can provide a remedy. This guarantees optimal surface cleanliness for thin-wire bonding as well as an increased yield.

ContactFind the Right Cleaning Solution for Your Power Modules Now

Zestron Whitepaper CollectionChallenges in the Production of Power Modules

How a cleaning process can help to increase the yield.