InsightsEnsuring Quality and Reliability: The Essential Role of Meticulous Assembly Cleaning

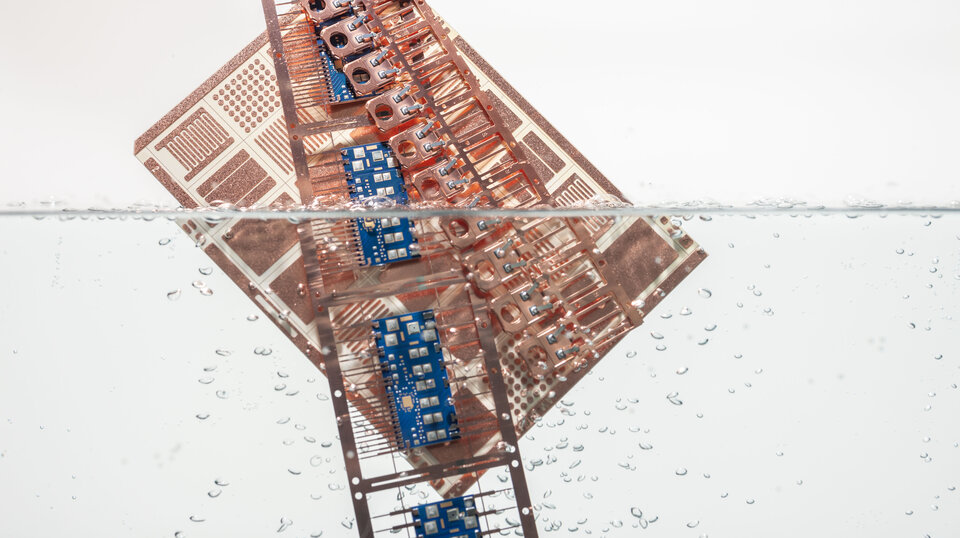

Cleaning PCBs: From flux residues to coating issues, a proper pcb cleaning process is essential for preventing defects and ensuring long-term performance. Especially in high-reliability industries, clean assemblies are the foundation for functional safety and product longevity.

PCBa CleaningReliable Technology Requires Reliable Cleaning

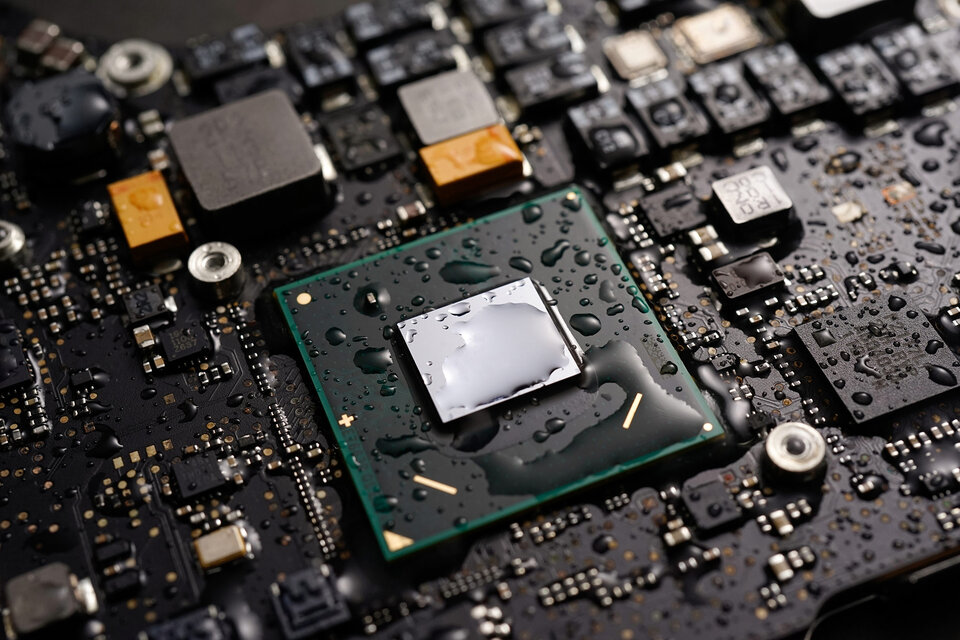

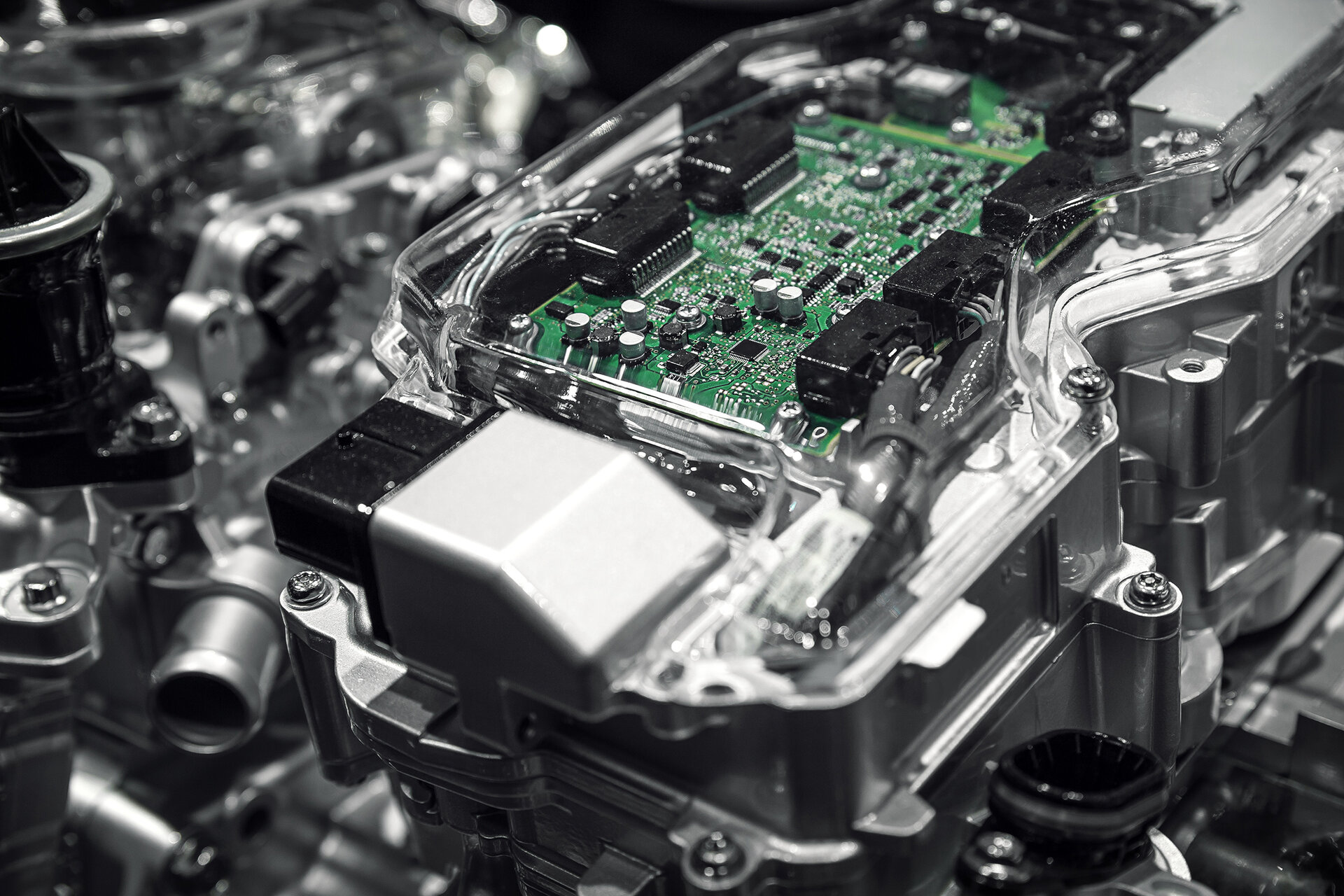

The importance of PCBA cleaning becomes especially clear when we consider the consequences of technical failures, which highlight just how dependent we are on these systems. In sectors where failures can have serious consequences — whether financial, health-related, or even life-threatening — this dependency becomes critical.

We are fully aware of the impact of technical failures and understand the crucial role that assembly cleaning plays. With our expertise and a wide range of cleaning agents, we are your reliable partner for ensuring high-performance and dependable electronics.

PCB CleaningA Must in Many Industries

In high-end industries, component cleaning is of paramount importance to ensure the highest reliability.

While "NoClean" manufacturing often suffices in the low-end sector, risk avoidance is paramount in the high-end sector. Whether in the automotive, telecommunications, aerospace, or military sector, the flawless operation of integrated technology is crucial for minimizing potential failure risks and ensuring safety

Assembly cleaningHow Does PCB Cleaning Work and What is ZESTRON's Contribution?

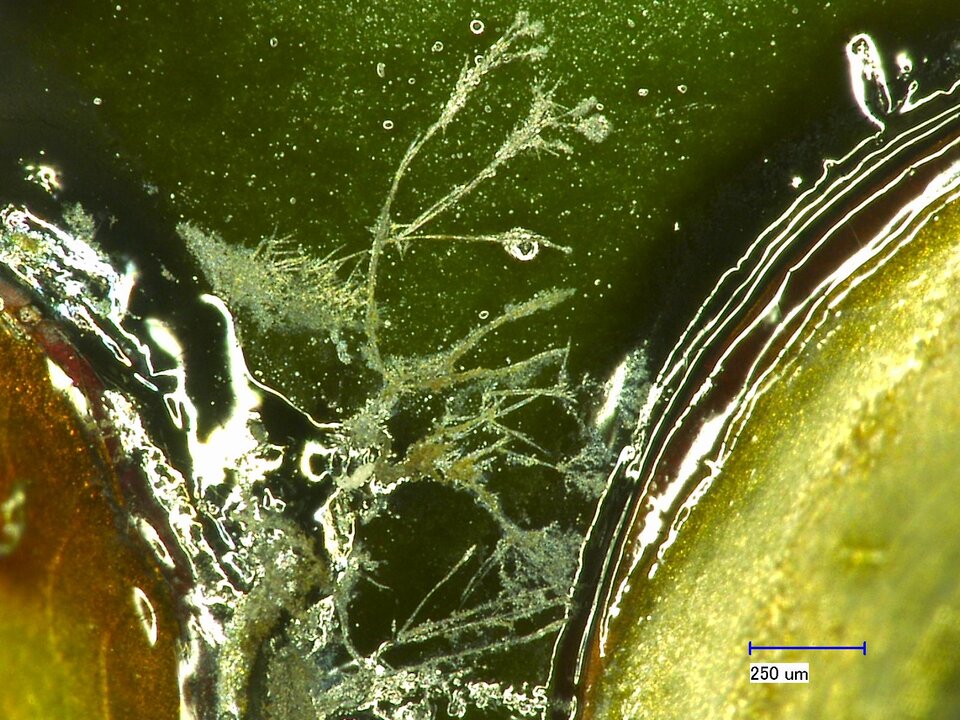

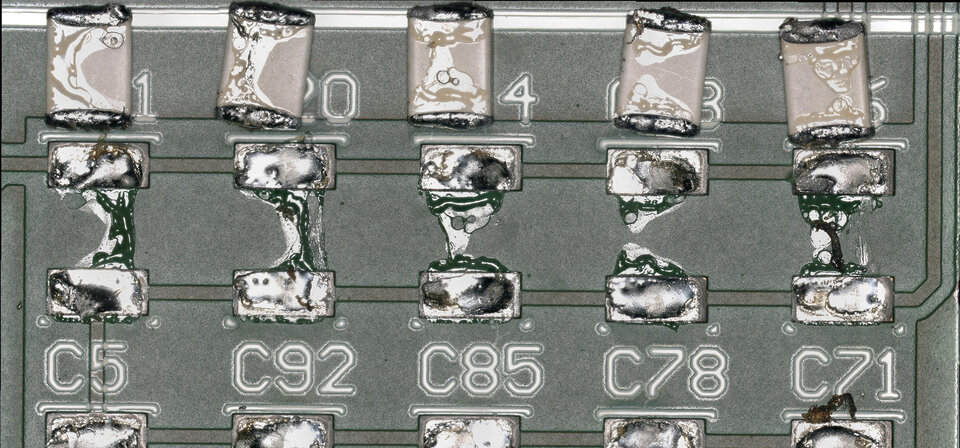

The cleaning of assembled printed circuit boards (PCB cleaning) is particularly concerned with the removal of resin and flux residues or the removal of production-related handling residues.

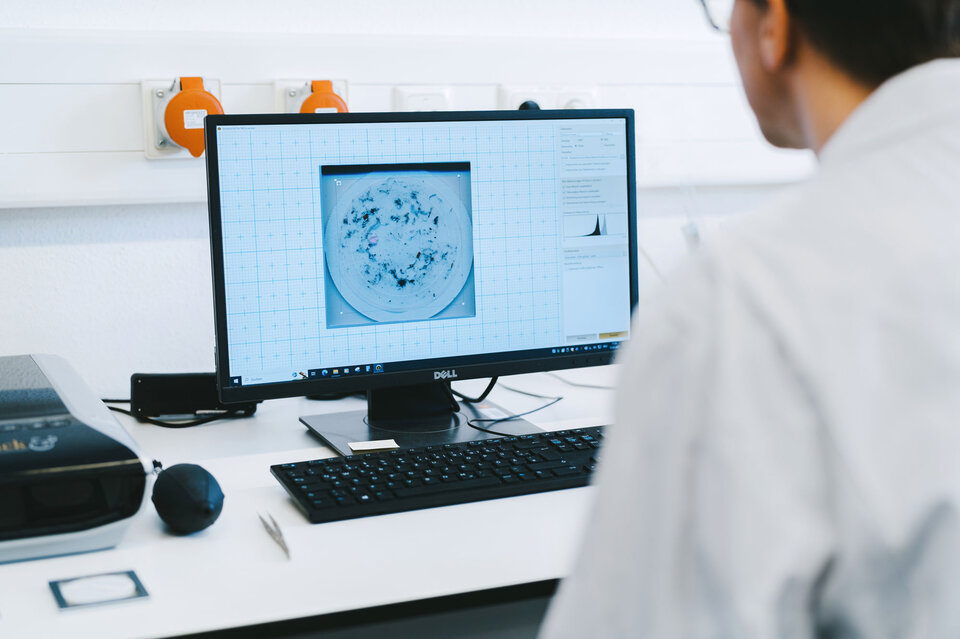

For this purpose, ZESTRON is constantly researching new cleaning methods and has been developing custom-fit solutions for every requirement for many years - individually, comprehensively and reliably.

REQUIREMENT Why is Assembly Cleaning Necessary?

The targeted use of an assembly cleaner has a significant influence on the subsequent process steps, such as bonding or protective lacquering. If resin and activator residues remain on the PCBs, this can result in poor adhesion of the bonds and the resulting defects such as heel cracks or lift-offs. Remaining residues can also lead to poor wetting of the coating or even to the protective lacquer peeling off, which can also result in malfunctions or field failures.

Let our experts advise you to find the perfect cleaning solution for your requirements!

CLEANING OF ASSEMBLIESWide Variety of Products and Applications

The module cleaners developed by ZESTRON are also well equipped for special challenges - such as the use of lead-free solder pastes, where there is a higher risk due to an increased resin content and more aggressive activator systems.

cleaning methodesThe right product solution for every requirement

Various types of cleaners are available for cleaning both lead-free and lead-containing assemblies:

FLEXIBLE APPLICATION, NO FLASH POINTWater-Based Cleaning

Water-based cleaners are characterised by their very wide process window, which allows the removal of all kinds of resin and flux residues from lead-free or lead-containing NoClean solder pastes.

They can be used very flexibly in a wide variety of cleaning processes.

One advantage of aqueous cleaning is a flashpoint-free process, which contributes significantly to work safety and storage, as well as high environmental compatibility due to the very low VOC (Volatile Organic Compound) content.

LONG bath lifeSemi-Aqueous Cleaning

Semi-aqueous cleaning processes are characterised by a high broadband capability, allowing all types of flux residues to be removed from lead-free or lead-containing NoClean solder pastes.

Typically, these processes do not use conventional alcohols, but modern solvents that are organically formulated and therefore free of halogens. These types of solvent cleaners have a very high bath loading capacity and thus allow very long bath lifetimes. Due to their surfactant-free formulation, they are also excellent rinsable by demineralised water.

fast and residue-free dryingWater-Free Cleaning

Modern solvent cleaners are used as cleaning chemicals. These are characterised above all by their broad formulation. Due to the polar and non-polar components in the cleaner, a wide variety of flux residues can be removed from lead-free or lead-containing NoClean solder pastes. Furthermore, these solvent cleaners can be uniformly distilled, enabling their use in cleaning machines with steam rinsing. Due to their surfactant-free formulation, they dry quickly and without leaving residues.