InsightsSMT Stencil Cleaning: Reliable Print Quality Starts With a Clean Stencil

Avoid misprints and ensure consistent solder paste application by thoroughly cleaning SMT stencils and screens — an essential step for reliable electronics production.

Stencil cleaningJust Another Task – or a Critical Process Step?

Stencil cleaning is often underestimated – yet it plays a key role in the overall quality of the production process.

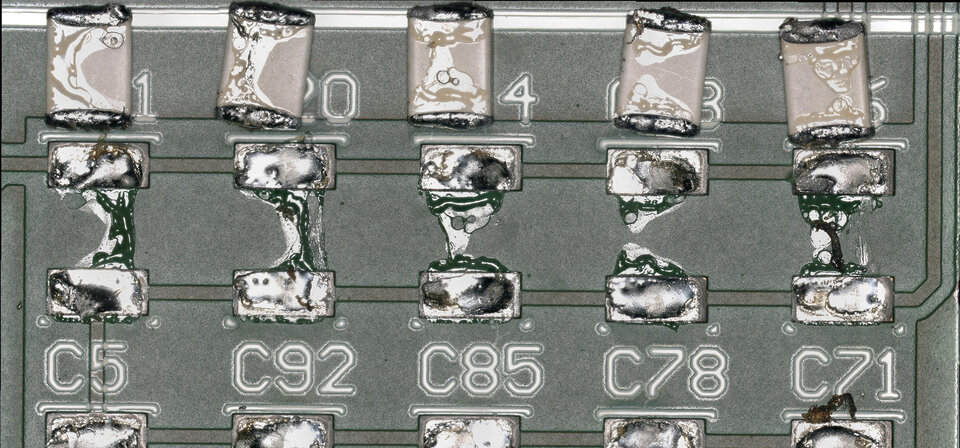

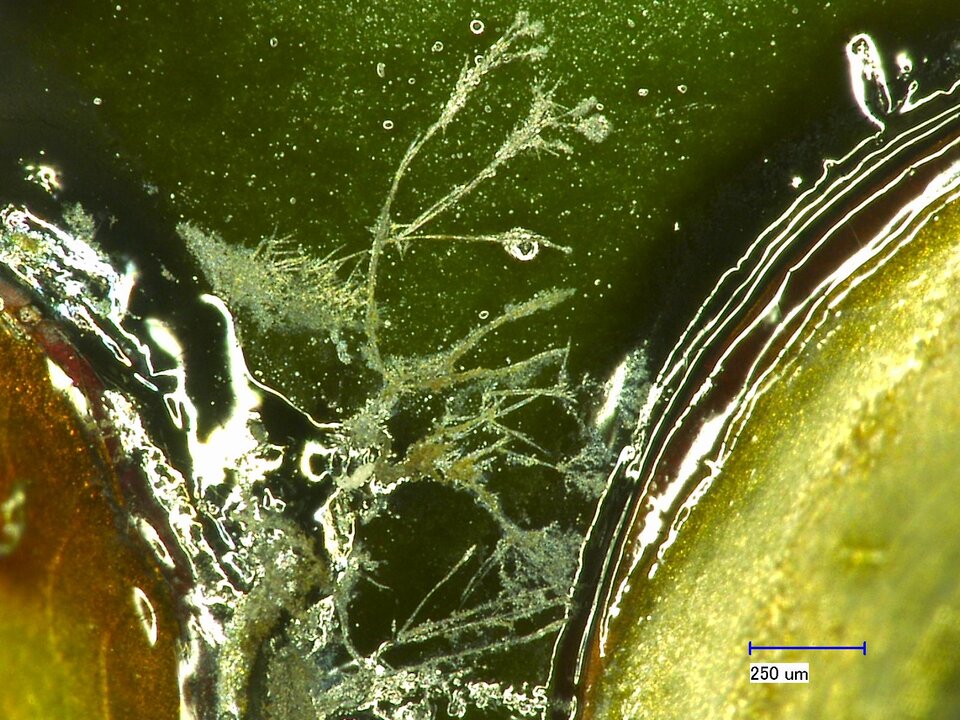

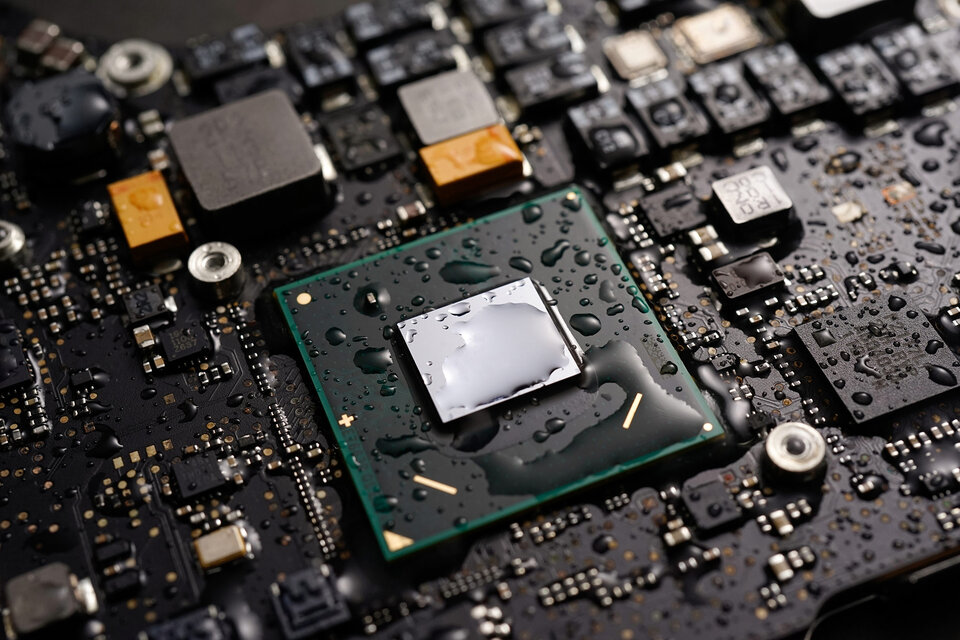

Residues on stencils impair paste transfer and can lead to soldering defects, short circuits, or failures. A controlled and reliable stencil cleaning process is therefore essential – not only for the quality of individual assemblies, but also for the overall stability of the SMT line. The choice of cleaning method, cleaning agent, and integration into the production workflow are all decisive factors.

stencil cleaningWhy SMT Stencil Cleaning Is Essential

A clean stencil or a cleaned screen is an important prerequisite for optimal printing results. Solder pastes, SMT adhesives, or thick film pastes are printed or applied through stencils or screens. Residues on the stencil surface can harden and cause printing errors, which is why thorough cleaning is essential at this early stage of production.

Various methods are available for cleaning stencils and screens, which can be tailored to individual requirements.

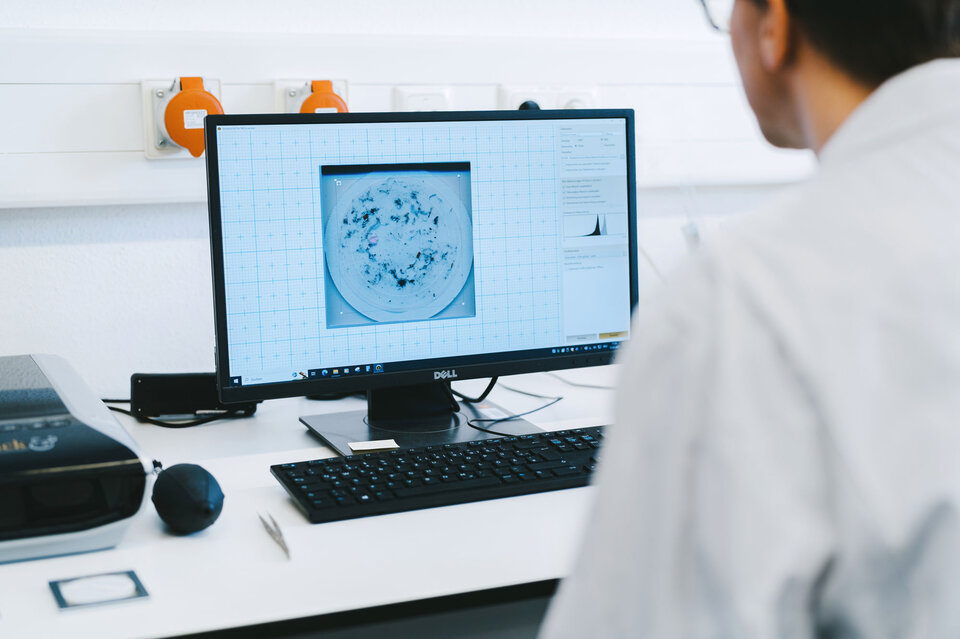

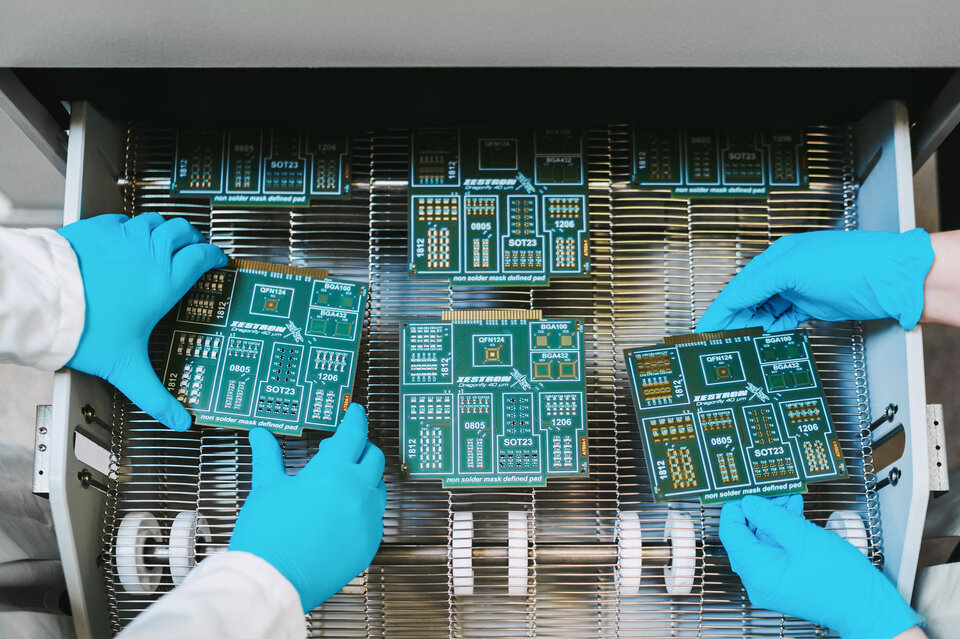

machine cleaningFor High Throughput

Reliable production of electronic assemblies requires precise work at every step of the production process. Especially in stencil cleaning, a machine cleaning method is often the best choice as it delivers reproducible cleaning results and significantly reduces mechanical damage. This way, optimal printing results and higher quality of the produced assemblies can be achieved.

manual cleaningFor Low Throughput

When the throughput is low, manual stencil cleaning can be a reasonable alternative to machine cleaning. However, some important steps should be taken to avoid damaging the stencil.

This includes, for example, the use of a lint-free stencil cloth and a gentle approach without too much force. If these points are considered, manual stencil cleaning can also lead to good cleaning results.

Solution for misprintsMisprint and Underside Cleaning

Even with the greatest care and thorough cleaning in the production of electronic assemblies, misprints on the board can occasionally occur. However, there is no need to worry - in such cases, misprint cleaning can provide a solution.

Cleaning of Misprints

Misprint cleaning enables the targeted removal of erroneously applied solder paste, resulting in higher quality of the produced assemblies and reduction in scrap. Particularly in the case of high-quality, double-sided assemblies that have already been soldered on one side, cleaning is recommended, as misprinted assemblies can be salvaged after cleaning instead of being discarded as scrap. With this process, misprints can be effectively eliminated.

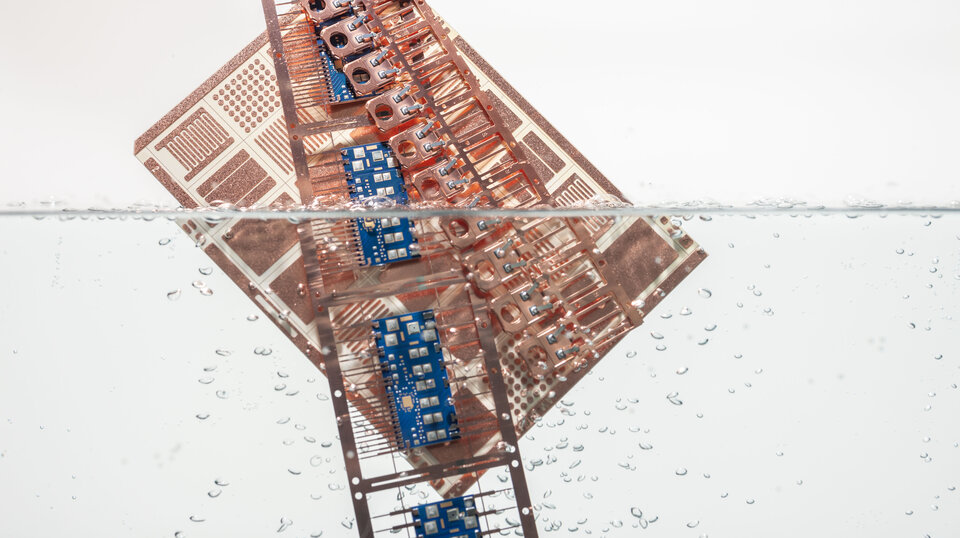

Underside Cleaning - SMT Printing

To achieve optimal and consistent printing results in SMT printing, it is important to regularly clean the underside of the stencils.

An important factor in this regard is the choice of cleaner, which should not only have good cleaning power and low media consumption, but also high compatibility with the solder paste used. Regular cleaning of the underside of the stencil can maintain a consistently high printing quality standard.

Stencil cleaningFind Your Product Now

A reliable cleaning of stencils is essential for error-free production in the electronics and solar cell industry. Residues from SMD adhesives and solder pastes can cause costly manufacturing errors. Our high-quality cleaners provide the solution for efficient cleaning, ensuring consistently excellent results.

OPEN QUESTIONS?Consistent printing results require a tailored stencil cleaning process

Get in touch – we’ll find the right solution for your production.

Whitepaper-CollectionModern Stencil Cleaning

In the production of electronic assemblies, solder pastes and SMT adhesives are applied using stencils. Due to ongoing miniaturization and high component densities, fine-pitch stencils are increasingly used.

To ensure consistently high print quality, regular stencil cleaning is essential. It prevents quality losses in subsequent processes and minimizes risks associated with inadequate cleaning.