A Clean Stencil Wins Half of the Battle

Stencil and screen cleaning for optimum printing results.

"If you miss the first buttonhole, you won't get anywhere with buttoning." - Johann Wolfgang von Goethe. This universal truth emphasizes the significance of paying attention to the initial steps and ensuring a meticulous approach. Similarly, in the context of cleaning electronic components, it highlights the importance of thorough and precise cleaning from the start.

stencil cleaningPrecision Begins in Detail

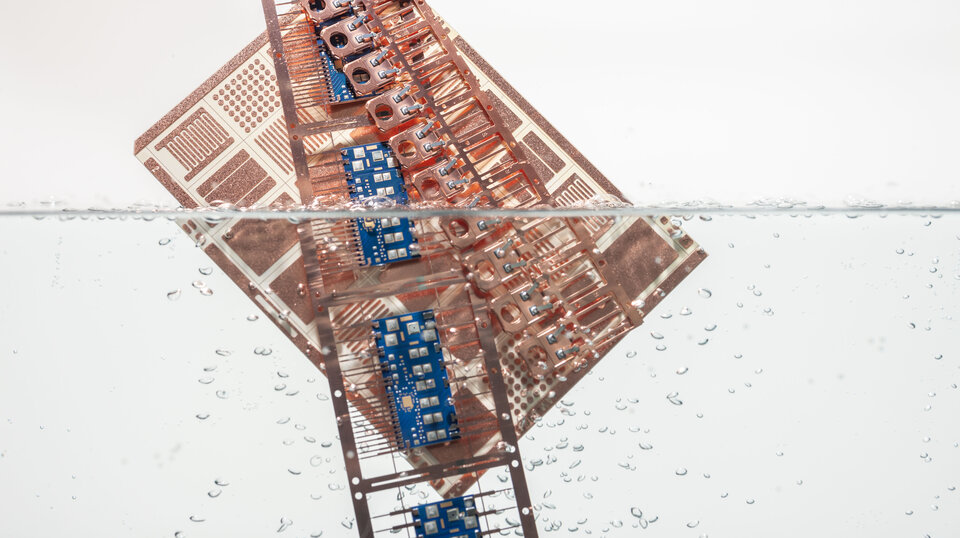

In the realm of electronic assembly production, stencil and screen cleaning can be considered the crucial "first buttonhole." During this stage, solder pastes, SMT adhesives, or thick-film pastes are printed or applied through stencils or screens.

However, residues left on the stencil surface can harden over time, leading to printing errors and compromised quality. As a result, cleaning becomes an essential step even at this early stage of production.

CLEANING METHODS Different Cleaning Process

When it comes to cleaning stencils, there are multiple options available depending on the specific requirements. For ensuring production reliability, mechanical stencil cleaning is often the preferred choice.

By utilizing mechanical stencil cleaning, manufacturers can achieve the desired level of cleanliness while mitigating the potential risks associated with alternative cleaning approaches. This ultimately contributes to improved production reliability and overall operational efficiency.

RequirementsDifferent Requirements

In addition to mechanical stencil cleaning, manual removal of residues on stencils is another option, particularly when the throughput is low. However, it requires careful execution.

When opting for manual stencil cleaning, it is essential to use a lint-free and residue-free stencil cloth. Care must be taken to handle the cloth gently and avoid applying excessive force, as this can potentially lead to damage.

cleaningMisprint and Underside Cleaning

Despite taking extensive cleaning measures beforehand, misprints on PCBs can still occur. Misprint cleaning provides a solution by allowing the removal of incorrectly applied solder paste from the base substrate and achieve the desired level of accuracy and functionality.

In the case of high-quality, double-sided PCBs that have already been soldered on one side, the value of cleaning becomes evident in a short span of time. Through the cleaning process, misprinted assemblies can be salvaged and do not have to be discarded as rejects.

Cleaning the underside of the stencil in the SMT printer is as important in achieving optimal and consistently high-quality printing results. The choice of the cleaner plays a significant role in this process, as it must possess not only effective cleaning power and low media consumption, but also excellent compatibility with the solder paste used.

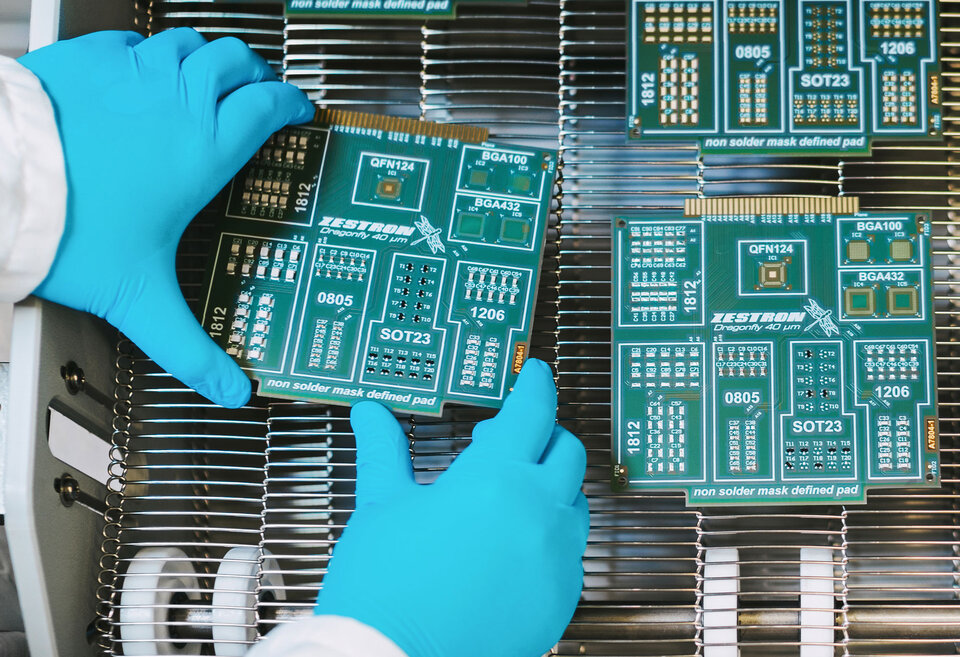

ZESTRON addresses these requirements by offering a range of cleaning products, both water-based and solvent-based, that ensure reliability and effectiveness in the cleaning process.

More short storiesThis might also interest you:

stencil cleaningFind your product now.

ZESTRON offers both water- and solvent-based products that guarantee reliability in the cleaning process.