InsightsMaintenance Cleaning: Not Just Cosmetics

Maintenance and Tool Cleaning: Ensuring Quality and Efficiency in Electronics Manufacturing

maintenance cleaning / tool cleaningKey to Quality in Electronics Manufacturing

Maintenance and tool cleaning are crucial in electronics production. Regular cleaning not only ensures the flawless operation of tools and machinery but also guarantees the high quality of the final products.

maintenance cleaning / tool cleaning Cleanliness Ensures Quality

Product quality starts with a clean production environment!

Maintenance cleaning has 3 main objectives:

-

Improving product quality

A clean production environment is the cornerstone for high-quality products. Clean tools and machines help to ensure that the electronics produced are reliable and error-free. -

Prevention of system failures

Contamination can lead to system failures. Regular maintenance cleaning removes deposits that could impair the functionality of machines and tools.

A reliable and trouble-free production process is supported by the use of clean tools and machines. -

Extending the service life of production tools and machines

Dirty tools and machines wear out more quickly. Cleaning protects them from premature wear, which extends their service life and reduces operating costs.

maintenance cleaning / tool cleaning Common Contaminations

In many cases, these are burnt-on flux residues and outgassing from electronic assemblies that occur during the soldering process. In addition, unsoldered solder paste, sinter pastes, coatings and SMT adhesives must be safely removed from various tools.

Maintenance cleaning can be implemented in different ways in a production facility. In addition to very good cleaning results, the cleaning process should of course also be cost-efficient and user-friendly. It is always advisable to consult experts in order to achieve the best possible results. This is where ZESTRON can help.

applicationsWhere Does Maintenance and Tool Cleaning Occur in Electronics Production?

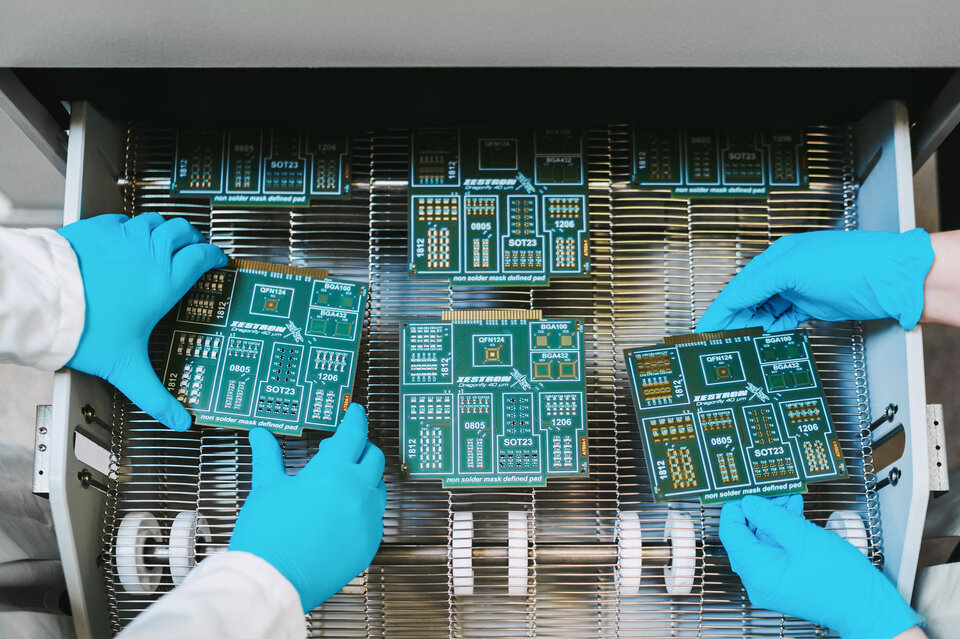

Solder Pallets / Carrier

During solder frame cleaning, heavily baked-on flux residues must be removed to ensure proper fixing of the assembly. If the product carriers are not cleaned regularly by machine, correct placement of the PCBA and optimum processing by the wave soldering system cannot be guaranteed. This typically leads to uneven soldering results on the assembly, which must be selectively reworked.

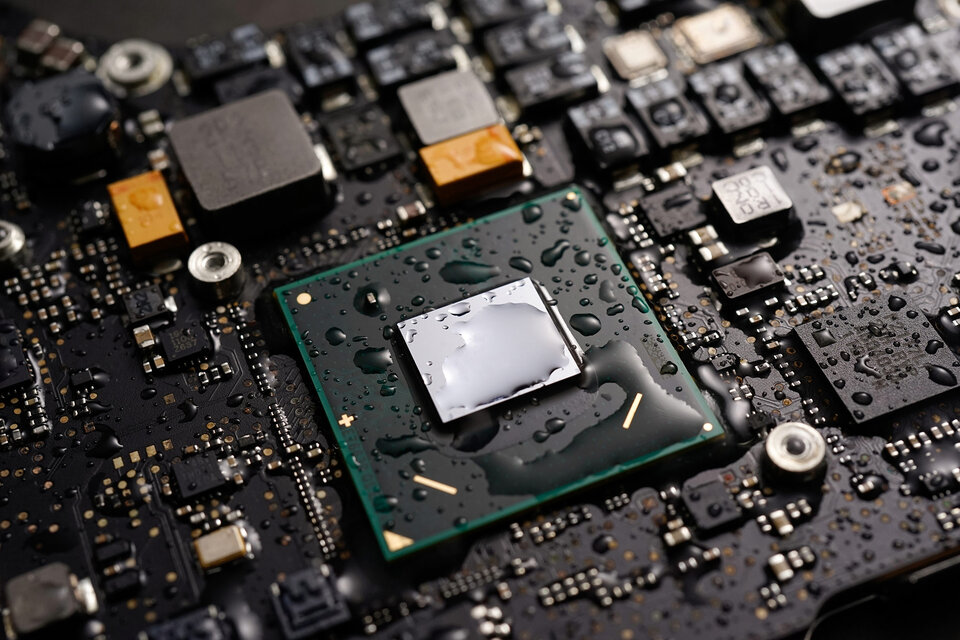

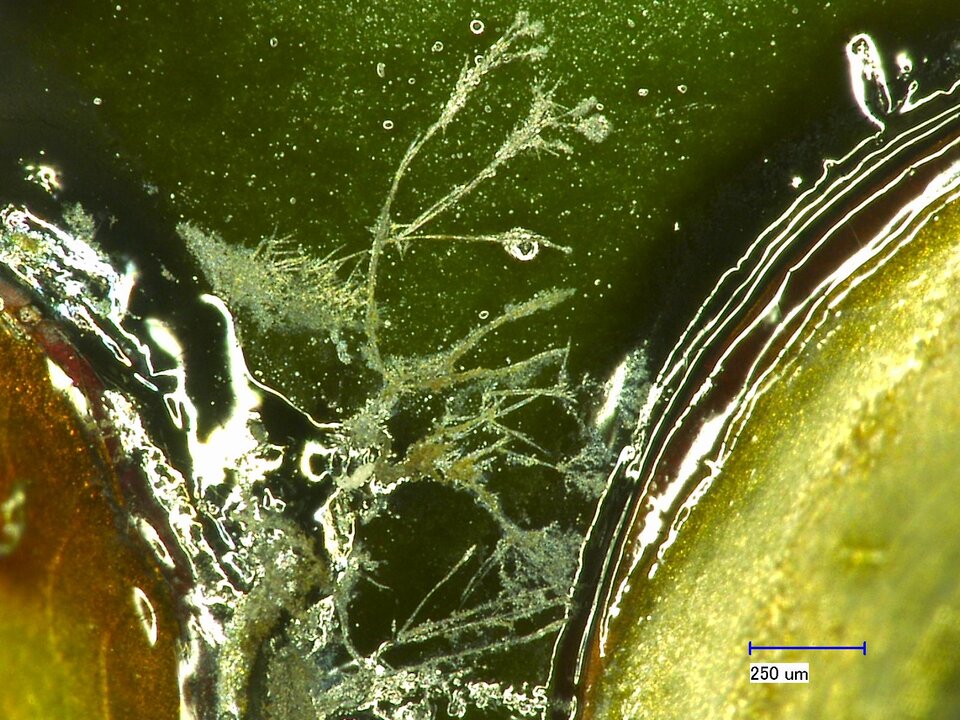

Condensation Traps / Filter

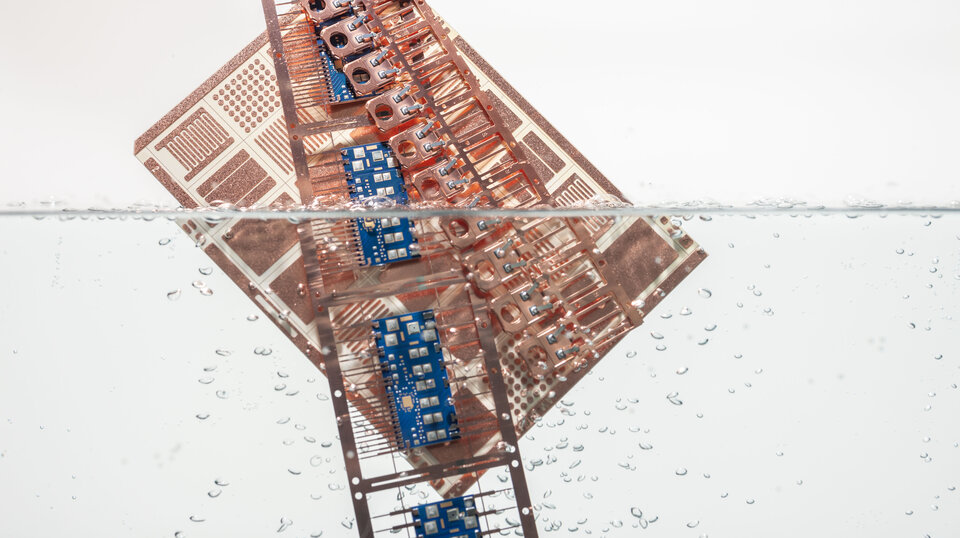

During the soldering process, outgassing and vapors from the solder paste are deposited on the condensation traps and filters, which successively reduce the degree of deposition. Regular cleaning allows the condensation trap to permanently absorb outgassing and vapors from the soldering furnace. This enables the PCBA to achieve consistent soldering results.

Reflow Oven / Wave Solder System

During the soldering process, evaporating flux and outgassing from the solder paste and solder resist deposit on the surfaces in the soldering oven. These impurities must be regularly wiped off manually, otherwise the desired peak temperature cannot be constantly achieved in each zone. This leads to an unstable soldering profile. In addition, impurities from gas emissions can be transferred to the next assemblies during subsequent soldering processes. The issue of occupational safety is also particularly important here

Product Recommendation

ATRON® SP 300

Product Recommendation

ATRON® SP 300

Product Recommendation

VIGON® RC 303

Coating Frame

In the conformal coating process, the assemblies for the coating process are secured in holders so that they can be moved through the painting system. With each new painting cycle, the parts come into contact with the coating material, which builds up. This means that cleaning is necessary after some time in order to be able to continue using the frames.

The use of aggressive stripper chemicals should be avoided for health and safety reasons.

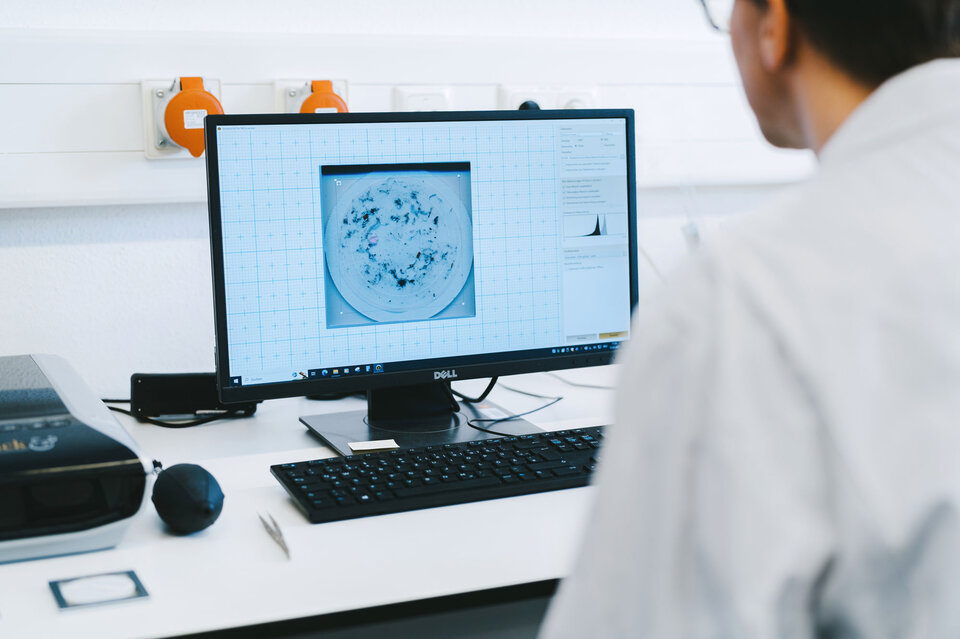

Dispenser Needles / Nozzles

The cleaning of dispenser needles involves the removal of epoxy adhesives

(e.g. SMT adhesives and conductive adhesives) or epoxy resins. SMD adhesives are applied to the electronic assembly/component via a dispenser with a needle. The dispensing needles made of aluminum or stainless steel are precise tools that should be reused.

Dispenser needles can be cleaned manually or mechanically.

Pick & Place Nozzles / Head

Pick-and-place machines work at high speed and with high precision. The placement head picks up the electronic SMT components from the feeder and places them on the PCB. During this process, impurities such as solder particles and dust can accumulate in the nozzles, which must be cleaned regularly. Similar to the dispenser needles, the pipette holders of the pick & place placement heads can be cleaned manually or automatically.

Product Recommendation

ATRON® DC

Product Recommendation

ZESTRON® HC

Product Recommendation

ZESTRON® HC

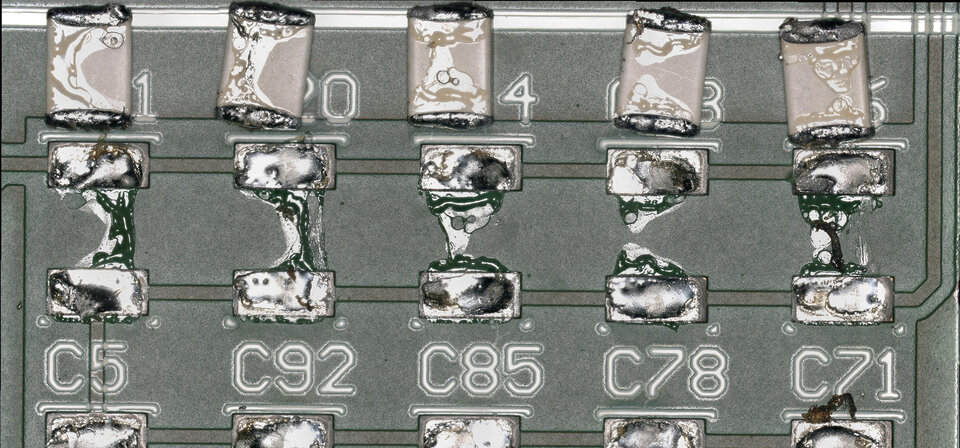

Squeegee (in SMT Printers)

With the help of a squeegee, the solder paste is applied to the PCB in the stencil printer through a screen/stencil at a defined pressure and speed. Like the stencil, the squeegee must be cleaned regularly to ensure that the solder paste is applied evenly. This is done manually at regular intervals. In addition, machine cleaning should also be carried out at defined intervals to ensure that all residues are completely removed.

Conveyor Fingers

During the wave soldering process, cross-contamination occurs when flux residues are deposited on the conveyor belt's transport fingers. These residues trap dust particles and other impurities, contaminating the transported PCBs.

Therefore, continuous cleaning of the conveyor fingers is crucial to ensure that the solder frames are properly guided over the wave.

Product Recommendation

VIGON® SC 200

Product Recommendation

VIGON® RC 303

more than just consultingEfficient Tool Cleaning

Are you looking for a more efficient cleaning process for maintenance or want to improve your current process? Let us help you!