InsightsMeasuring the Cleaning Agent Concentration for Reliable PCBA Cleaning - a Useful Guide

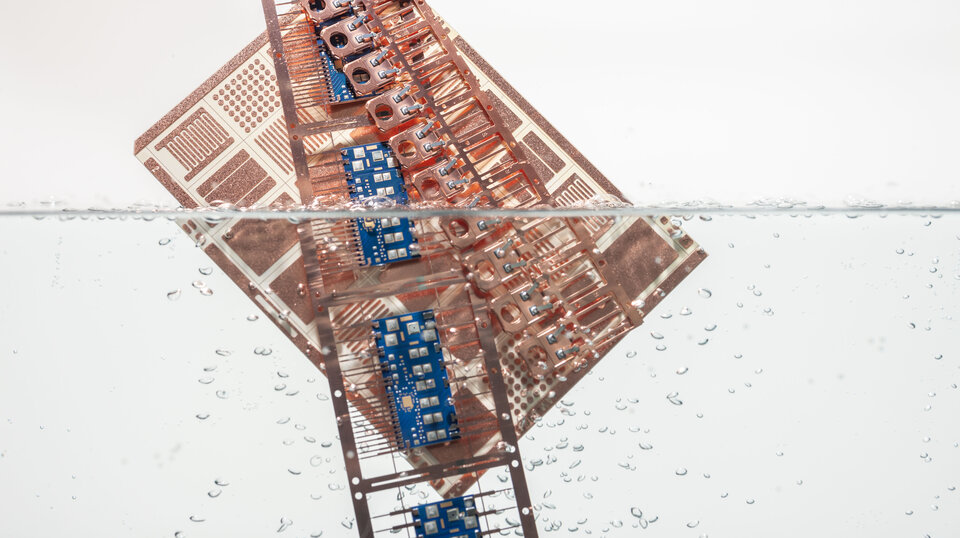

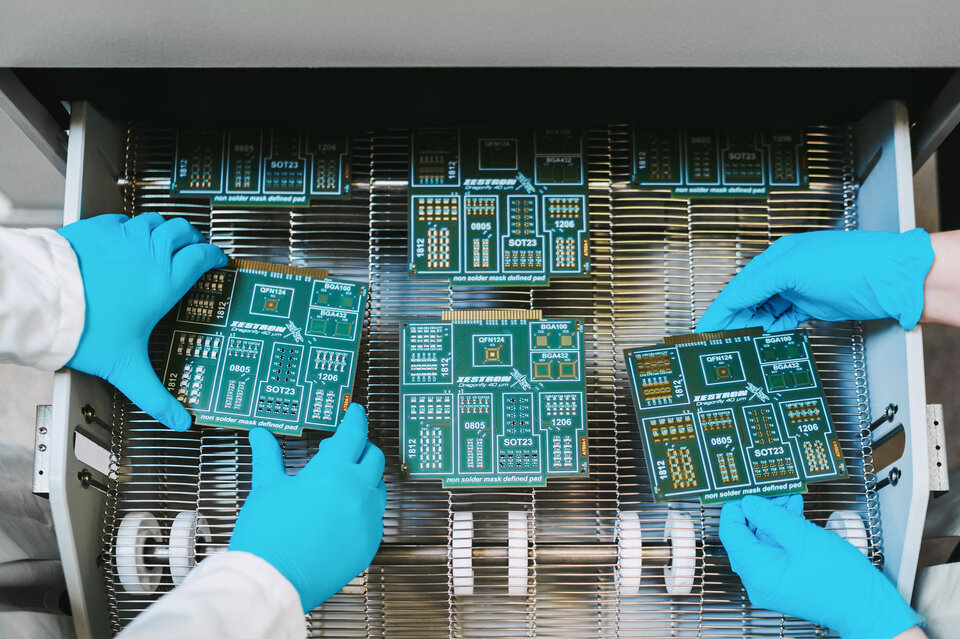

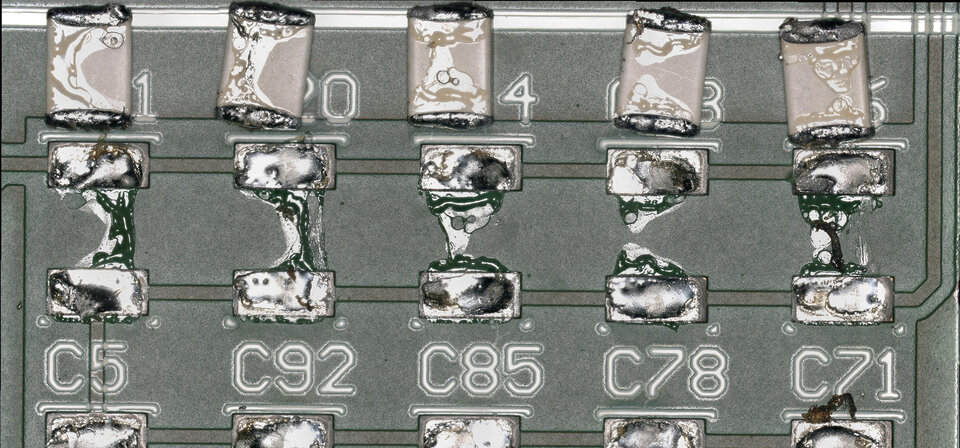

Concentration monitoring in electronics cleaning is an important step in ensuring good cleaning results and indirectly checking the surface cleanliness of the PCB assemblies.

Concentration monitorinWhy is Concentration Monitoring Useful in PCB Assembly Cleaning?

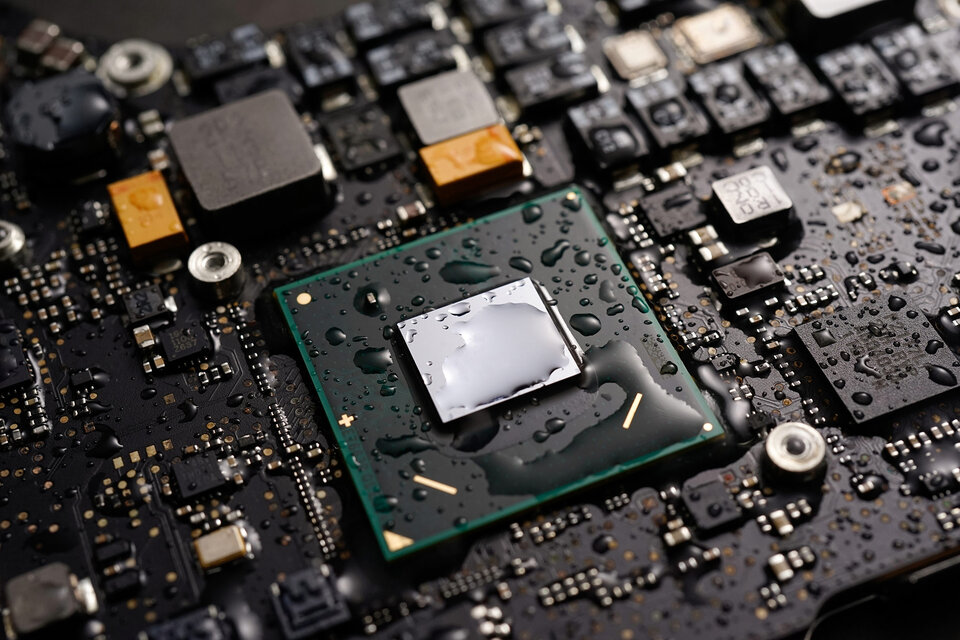

The correct cleaner concentration in the cleaning machine is important to achieve continuous and good cleaning results. Too low a concentration generally leads to poorer cleaning results, whereas too high a concentration can cause material compatibility problems and high cleaning costs. It is also becoming increasingly important not only to have consistently good cleaning results, but also to be able to prove them. Many companies want their suppliers to provide evidence of how the quality of the supplied parts is ensured. If the cleaner concentration is monitored regularly (or preferably continuously), this documentation can be very helpful in the event of audits or complaints.

process optimizationTo Summarise, Concentration Monitoring Supports the Following Objectives:

-

Stable process due to consistent quality of the cleaning medium

-

Optimisation of process costs by avoiding excessive cleaner consumption

-

Avoidance of poor cleaning results due to late dosing of detergent concentrate or DI-water

-

Documentation to allow the possibility of process traceability (e.g. for ISO 9001)

concentration monitoringHow Does a Fluctuating Concentration in the Cleaning Bath Come About in the First Place?

There can be various reasons for deviations from the desired concentration. During the cleaning process, process-related evaporation of cleaning agent can occur, especially at high cleaning temperatures. The extraction or drag-over of detergent into the water of the rinsing stages also contribute to changes in the detergent concentration in the cleaning system.

The point at which the detergent concentration in the process is significantly or critically over- or under process depends on the respective cleaning process, the medium itself and the goods to be cleaned.

proceduresWhat Methods of Concentration Monitoring are Available?

There are various manual and automatic measuring methods for measuring the detergent concentration in the system. Here is a brief overview:

01 | Manual Measuring Methods

Conventional acid-base titration

In this test kit, the concentration of alkaline or acidic media is determined using this component as a representative. In this method, a test indicator is added to a defined volume of the bath sample until a colour change occurs. The concentration of the cleaning medium is calculated from the used titration medium. It must be noted that the result with this method is affected by the contamination of the bath. In addition, it cannot be applied with pH-neutral cleaning agents.

Product recommendation:

Easy Bath Control Kit

Phase separation method

This is also a test kit that provides a reliable and correct concentration measurement even with a loaded cleaning bath.

A reaction solution is added to the bath sample, which separates the active components of the cleaning medium. As the reaction takes place in a scaled measuring cylinder, the concentration can be determined with an accuracy of around ±2 % by reading off the volumes present. The method offers the advantage of being able to analyse alkaline and pH-neutral detergents.

Product recommendation:

Bath Analyzer 20

Refractive index

This parameter changes primarily due to the organic content contained in the medium or the organic composition of the cleaning medium. In principle, the concentration of many cleaning media can be determined by measuring the refractive index. However, this is only recommended for a fresh cleaning bath, as the bath loading, for example due to flux, can strongly influence the measurement accuracy and stability.

02 | Automatic Measuring Methods

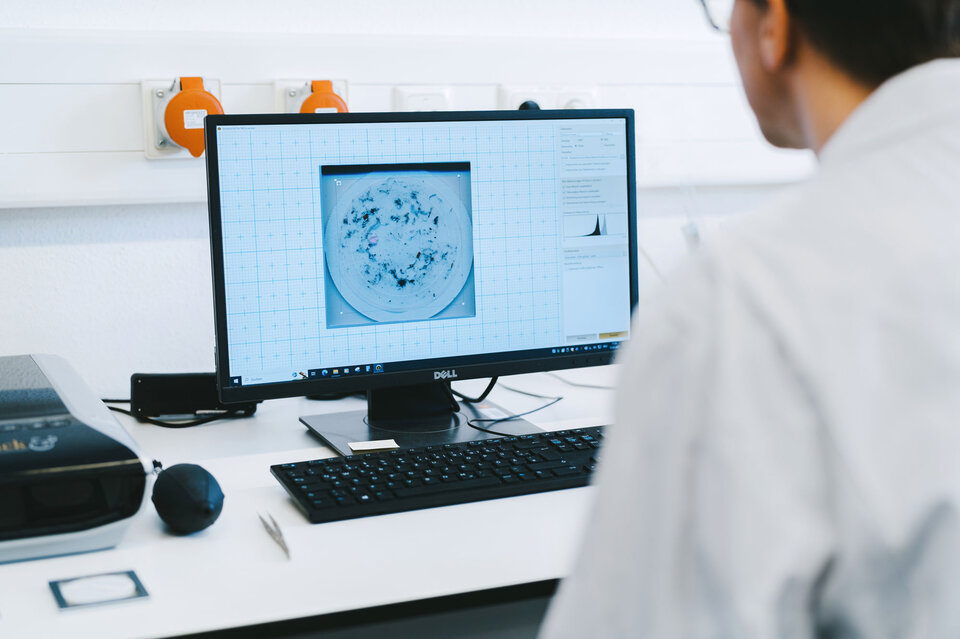

In contrast to manual methods, automatic processes enable permanent concentration monitoring in the cleaning system and therefore seamless documentation. The latter is becoming increasingly important, especially regarding audits or supplier evaluations. The two most common methods are described in more detail below.

Ultrasonic

This device measures a measurement parameter with the ultrasonic transit time. The speed of sound is then calculated from this transit time and the known distance between the transmitter and receiver. The concentration can then be calculated from this. However, the fact that there is only one measurement parameter means that this method is susceptible to process disturbances such as air bubbles in the measurement section.

Acoustic measurement method

The main advantage of this method is the high measuring accuracy and stability, which is guaranteed by three measured parameters instead of just one.

An acoustic signal is continuously sent through the liquid while the cleaning liquid flushes the sensor. A receiver registers the acoustic signal after it has been reflected several times by the tube wall of the sensor. Several analogue-to-digital converters analyse the signal and determine the three parameters signal time period, amplitude and signal dampening.

Product recommendation:

ZESTRON EYE

our supportUltimately, a Cleaning Process is Only as Good as its Monitoring.

If you have any questions about the various measurement methods or would like a quote, please contact us.

whitepaper-collectionCleaner Concentration Monitoring for High-Reliability Electronics

Find out how an automotive supplier improves the quality of the power module cleaning process by continuously monitoring the cleaning concentration. New methods increase efficiency.