InsightsVDA 19: Technical Cleanliness – The Key to Preventing Particle-Induced Failures

How innovative cleanliness concepts based on VDA 19 ensure the reliability of electronic components.

requirements and guidelinesTechnical Cleanliness Across the Supply Chain

In the automotive industry, Technical Cleanliness (TecSa) has played a crucial role for years and is becoming even more important with advancements in electromobility (e.g., battery management systems and inverters) and autonomous driving (e.g., camera systems). Increasing demands for reliability and durability require ever-stricter measures throughout the supply chain to prevent particle-induced failures.

To ensure this, industry standards such as VDA 19, ISO 16232, the ZVEI guideline "Technical Cleanliness in Electrical Engineering," and IEC TR 61191-7 mandate the consistent implementation of TecSa concepts. These guidelines not only support particle analysis but also help optimize processes and workflows along the value chain, reducing risks efficiently.

Technical cleanliness according to VDA 19Particle Reduction: Feasibility vs. Cost Efficiency

From both a technical and economic standpoint, it is neither practical nor necessary to manufacture components or surfaces entirely free of particles and fibers. Instead, the goal is to minimize potentially harmful particles to a level where they do not impact production or the long-term operation of a product. Alternatively, the harmlessness of existing particles can be verified, and their acceptable limits can be defined in coordination between the user and the manufacturer.

This balance between technical feasibility and economic efficiency is crucial for the success of a TecSa strategy. A holistic and iterative approach that considers all influencing factors requires in-depth expertise and comprehensive process optimization. Many companies face challenges in achieving an optimal cost-benefit ratio, as they must balance short-term financial goals with long-term quality requirements.

The following diagram illustrates the TecSa strategy, highlighting the key influencing factors and steps for reducing particle-related risks in the production process.

Tecsa-strategyTecSa Management

When establishing and implementing a TecSa management system, all workflow phases must be considered, with a primary focus on ensuring technical cleanliness. It is crucial to involve key stakeholders from all six areas early in the process and actively integrate them into the TecSa management requirements.

value propositionOur Support for Your Technical Cleanliness

Successfully addressing these challenges requires an experienced partner with a deep understanding of both technical and economic requirements.

The ZESTRON R&S team offers extensive expertise in:

-

Developing and implementing a customized TecSa concept

-

Ensuring compliance with technical requirements (standards & regulations, e.g., VDA 19)

-

Considering cost efficiency in all process steps

As an independent service provider, we specialize in developing holistic and efficient solutions tailored to your specific manufacturing processes.

The following diagram illustrates the control loop, outlining the key steps for the successful and sustainable implementation of Technical Cleanliness in your processes.

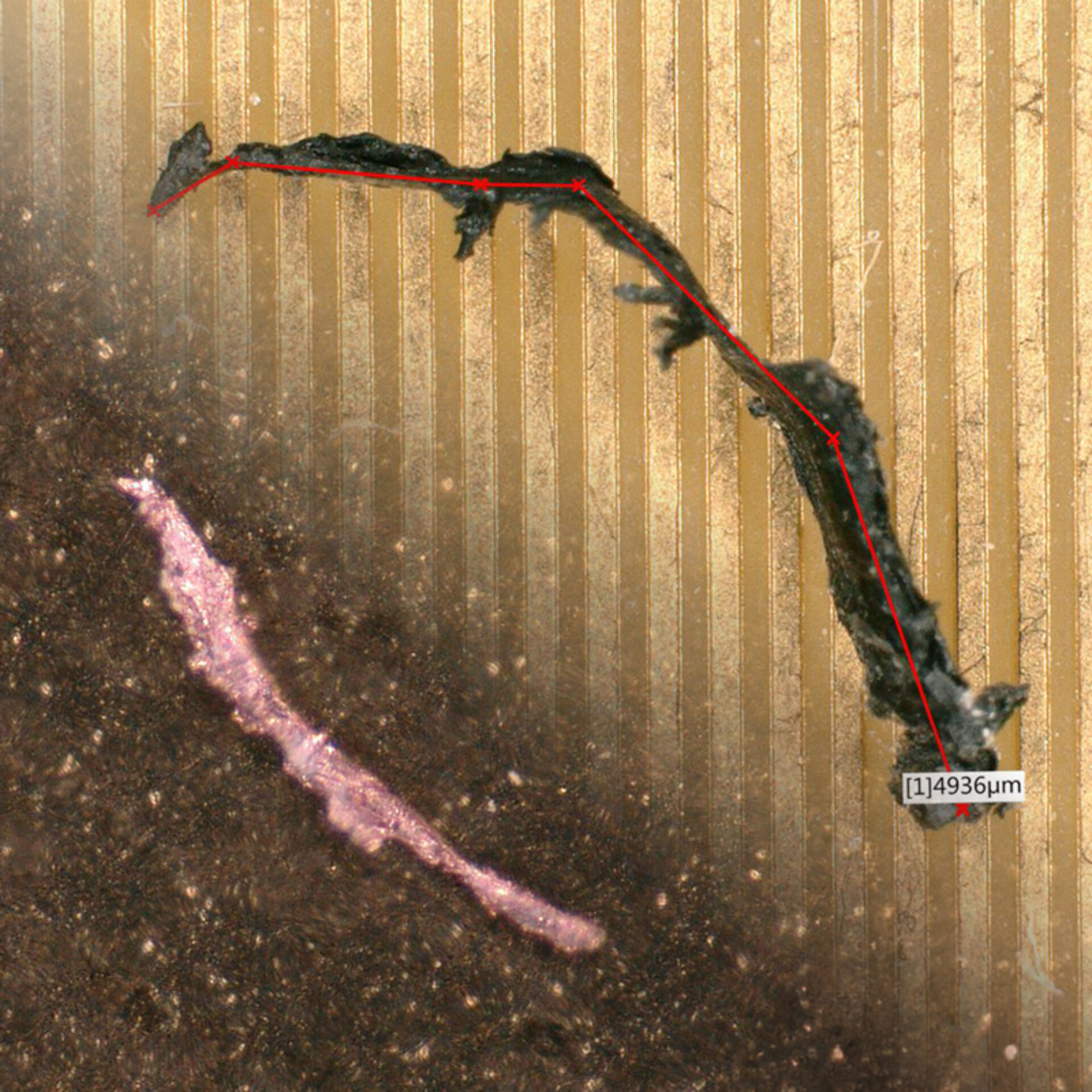

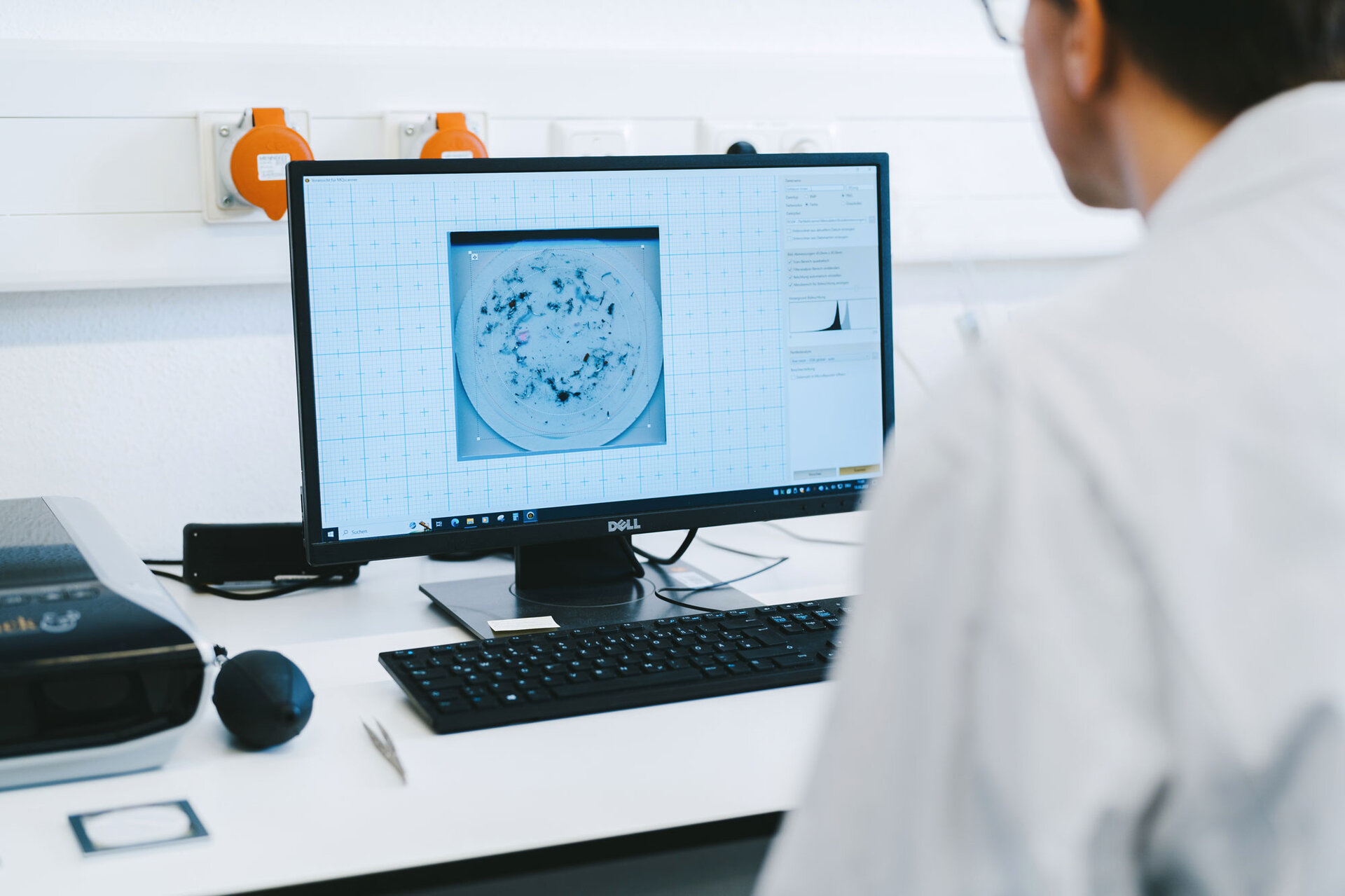

Ensuring Technical Cleanliness requires more than just determining the number of particles. A comprehensive analysis of particle types, their sources, and their potential impact on functionality and reliability is crucial. Only through this holistic approach can well-founded measures for reducing particle contamination be developed and effectively implemented.

This complexity is clearly illustrated in the diagram, highlighting the various steps and influencing factors essential for achieving sustainable Technical Cleanliness.

Technical cleanlinessContact Us for Your Customized

TecSa Concept

With our experience and industry expertise, we help you integrate Technical Cleanliness sustainably into your production—reducing risks, optimizing workflows, and enhancing product quality.

assistance moduleTechnical Cleanliness

Particulate contamination endangers the reliability of assembled printed circuit boards. Our tailored module helps you prevent risks at an early stage or effectively resolve existing issues. Fully customized to your specific requirements.

whitepaper-collectionTechnical Cleanliness in Electronics Manufacturing

Discover the risks of particle contamination in the electronics industry and explore effective cleaning methods to ensure technical cleanliness. Request information now to meet customer expectations and reduce particle loads.