Technical Cleanliness

Are you facing challenges with particulate contamination on your electronic assemblies, or do you want to protect your manufacturing process against such risks right from the start?

Our Technical Cleanliness module is not a standard solution but a fully customized one, specifically designed to address your company’s individual challenges and specific needs.

DetailsAt a Glance

Date

Arrange your preferred date with us.

Location

Choose your preferred location: ZESTRON Baar-Ebenhausen, Your Company or Online

Fee

4.900 € plus VAT

Included Services:

-

Analysis and preparation of the documents you provide, tailored to your specific challenge.

-

Access to presentation materials in advance.

-

Evaluation session customized to your requirements.

-

One-hour follow-up meeting to review implementation in daily operations (approx. 3 weeks after training).

assistance moduleWhat to Expect

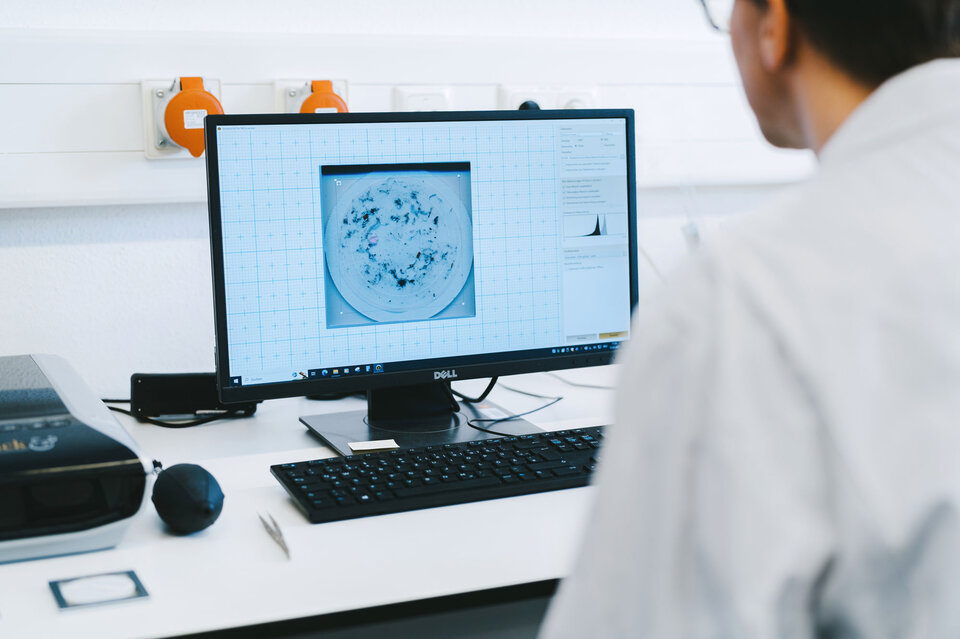

Ensuring ionic and film cleanliness while assessing particle-related risks is crucial for power electronics and sensitive sensors in driver assistance systems. Contaminants can cause damage to seals, circuits, and other critical components.

Our Technical Cleanliness module provides in-depth risk assessment and customized risk mitigation strategies, tailored specifically to your company's needs and product requirements.

If you are already facing specific challenges with particle contamination, we adapt the content individually to develop the optimal solution for your situation.

Background Knowledge

- Standards and Regulations: Deepen your understanding of key standards such as VDA 19.

- Knowledge-Based Approach: Familiarize yourself with the ZVEI guideline for electronics applications, including examples of particle sources.

- Risk Assessment of Particles: Learn methods for evaluating particle contamination.

Applied Practice

- Strategy Development for Particle Control: Work with our expert team to develop tailored strategies for preventing and minimizing particles.

- Verification Methods: Identify potential sources of particle contamination specific to your application.

- Application to Your Use Case: Together, we develop solutions that align with your working environment and production processes.

- Confidential Setting: Secure and discreet handling of your data, with an NDA available upon request.

- Personalized Consultation: Tailored guidance on your current challenges.

- Individual Case Analysis: Focus on your specific application and potential solutions.

- Clear Overview: Direct insights into particle risk assessment.

- Practical Methods: Risk assessment procedures for everyday use.

- Reduction Strategies: Effective approaches to minimizing or preventing particle contamination.

- Immediate Implementation: Integration of acquired knowledge into your daily work.

- Proactive Problem-Solving: Strategies to manage and effectively prevent future challenges.

Our specialized assistance module is designed not only to provide you with a fundamental understanding of the chosen topic but also to explain all relevant standards and present possible approaches through best-practice examples.

We conduct a detailed analysis of your specific challenges to develop tailored solutions together with you. Our expert team supports you with professional guidance and extensive industry experience.

This assistance module includes:

- Analysis and preparation of the documents you provide, tailored to your specific challenges.

- Access to presentation materials in advance.

- Evaluation session customized to your requirements.

- One-hour follow-up meeting to review implementation in daily operations (approx. 3 weeks after training).