Dendrites, Creepage Distances, and Deposits on Electronic Assemblies – All Consequences of Electrochemical Migration?

An overview of dendritic failure mechanisms and their associated failure patterns, illustrated through practical examples.

Dendrite formationMoisture-Induced Corrosion: A Threat to Your Assemblies

Moisture-induced corrosion during the operation of electronic assemblies often leads to functional failures due to parasitic currents. The reason: conductive paths form between contacts with different potentials on the component surface. This failure pattern—commonly referred to as deposits, creepage paths, or ion migration—begins when two contacts are bridged by a thin water film or droplet.

Small distances between contacts, ionic contamination, and pre-damage or quality defects in insulation materials further accelerate this failure mechanism.

Contact us – we will provide targeted support for your challenge

root cause analysisEffectively Resolving Dendritic Failures

Failures in reliability tests and field failures often involve assemblies with dendritic failure patterns. Through our in-depth root cause analysis, we not only identify the underlying failure mechanism but also develop targeted measures to help our customers prevent future failures and sustainably improve their products.

failure diagnosisMechanisms That Promote Dendritic Structures

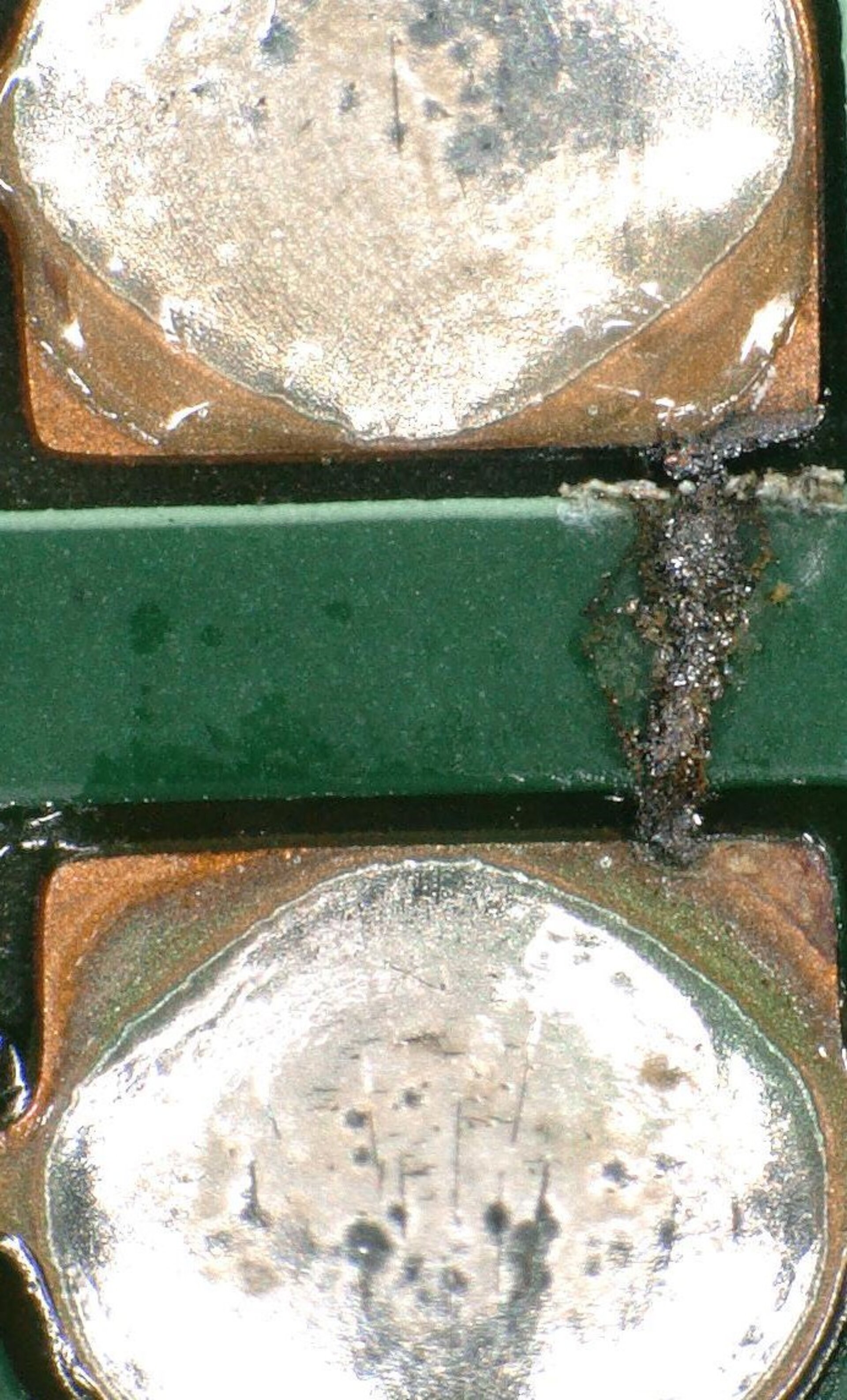

Electrochemical migration (ECM) is one of the most common failure causes in signal electronics operating at voltages below 3V. The presence of visible dendritic structures growing from the cathode to the anode often supports this initial hypothesis. However, other mechanisms, such as electromigration, electrocorrosion, or whisker formation, can also produce similar dendritic failure patterns.

In high-voltage applications and power modules, additional phenomena like electrical and electrochemical treeing, as well as Anodic Migration Phenomenon (AMP), play a critical role.

To precisely analyze dendritic structures and other failure mechanisms, we rely on proven investigation methods.

Below, we illustrate our approach with two specific case examples.

from practice 101 | Failure Diagnosis Through Targeted Analysis

Initial Root Cause Analysis

-

Are precipitates or dendrites present?

→ Clearly visible dendrites -

Is the growth direction recognizable?

→ Recognizable growth direction from cathode to anode

Further Evaluation

-

What is the elemental composition?

→ Copper -

Determination of exact structure

→ Dendrites with a defined growth direction

from practice 201 | Failure Diagnosis Through Targeted Analysis

Initial Root Cause Analysis

-

Are precipitates or dendrites present?

→ Not clearly identifiable -

Is the growth direction recognizable?

→ No

Further Evaluation

-

What is the elemental composition?

→ Tin -

Determination of exact structure

→ Dendrites with growth direction and precipitates

02 | Interpretation of Analysis Results

The presence of a dendritic structure with a clearly identifiable growth direction from the cathode to the anode supports the hypothesis of electrochemical migration (ECM).

Further evaluation provides the decisive proof: Higher magnification reveals detailed structural features and growth direction, while elemental composition analysis confirms that the dendrite consists primarily of metallic copper. Since copper is the material of the circuit traces, this leads to the logical conclusion that ECM is the underlying failure mechanism.

02 | Interpretation of Analysis Results

Dendrite-like structures and non-directional deposits are visible, but no clear growth direction can be identified.

Further evaluation, however, reveals an overlap of tin dendrites growing from the cathode to the anode, along with non-directional tin-containing deposits.

In both cases, the tin originates from the terminations of the SMT component. The directed tin dendrites initially confirm the hypothesis of electrochemical migration (ECM). Additionally, this example indicates the presence of the Anodic Migration Phenomenon (AMP), which causes tin-containing deposits originating from the anode. This suggests a combination of ECM and AMP as the underlying failure mechanisms.

approaches to mitigationWhy Do ECM and AMP Occur?

In both practical examples presented, our investigations successfully identified the failure mechanism. However, the root cause—the fundamental reason behind the occurrence of Electrochemical Migration (ECM) and the Anodic Migration Phenomenon (AMP)—remains unanswered.

So why do these phenomena occur in both cases?

03 | Next Steps

In this example, additional analysis revealed an increased ion load across the entire assembly surface. The detected ions included chloride and bromide, which, due to their hygroscopic properties, attract and retain moisture from the air.

This leads to the formation of water films and droplets between the contacts, creating the necessary conditions for Electrochemical Migration (ECM).

→ Solution Approaches

-

The specification of the solder paste and flux should be checked for "halogen-free" compliance and clarified with the supplier in case of deviations.

-

Reducing ionic contamination can help minimize failure risk. This can be achieved through measures such as cleaning the assembly to remove residual ions.

03 | Next Steps

In this example, additional analysis did not reveal an increased ion load. Instead, in the fully assembled product, a thermally inert mass was found inside the enclosure, positioned directly above the affected area.

During temperature fluctuations, water preferentially condenses at this location and drips from the enclosure onto the affected surface.

→ Solution Approaches

-

The enclosure design and installation conditions should be reviewed and optimized to minimize the risk of moisture ingress.

-

Active dehumidification of the surrounding air, such as through ventilation or airflow control, can help reduce moisture accumulation.

years of expertisePreventing Failures and Securing Processes

Many of our customers conduct extensive testing on their electronic assemblies, including condensation testing (K15), cyclic damp heat (K08/09), constant damp heat (K14), salt spray (K06/07), IP protection testing (K10), H3TRB, corrosive gas testing, and splash water shock tests.

When anomalies such as low resistance, short circuits, or optical changes occur, they turn to us for expert analysis.

We also specialize in investigating field returns exhibiting issues like creepage paths, ion migration, black spots, dendritic growth, or deposits.

Our goal is to precisely analyze root causes and develop targeted countermeasures—ensuring SOP timelines are met and costly recalls are avoided.

Contact usFailures in electronic assemblies require fast and precise solutions.

With our expertise, we ensure your products remain reliable and costly recalls are avoided.

assistance moduleFailure Analysis for Corrosion and Leakage Current

Corrosion and leakage currents are among the most common causes of failures in electronic assemblies. With this module, you will receive in-depth analyses and practical strategies to identify risks, prevent failures, and ensure the long-term reliability of your electronics.