Purity and Bath Analyses in Electronics Manufacturing

Purity determination of electronic assemblies is a central component of quality assurance in electronics manufacturing.

Cleanliness & bath analysisReliable Results,

Expert Interpretation

With our purity and bath analyses, we provide you with well-founded results and interpretations. We examine your entire cleaning process using a wide range of test methods – from surface cleanliness to bath monitoring.

Our detailed technical reports, including image documentation, ensure maximum transparency and traceability. In addition, we assess the potential impact of residual contamination and give you concrete recommendations for optimizing your processes.

cleanliness analysis from a single sourcePrecision You Can Trust – Down to the Micron

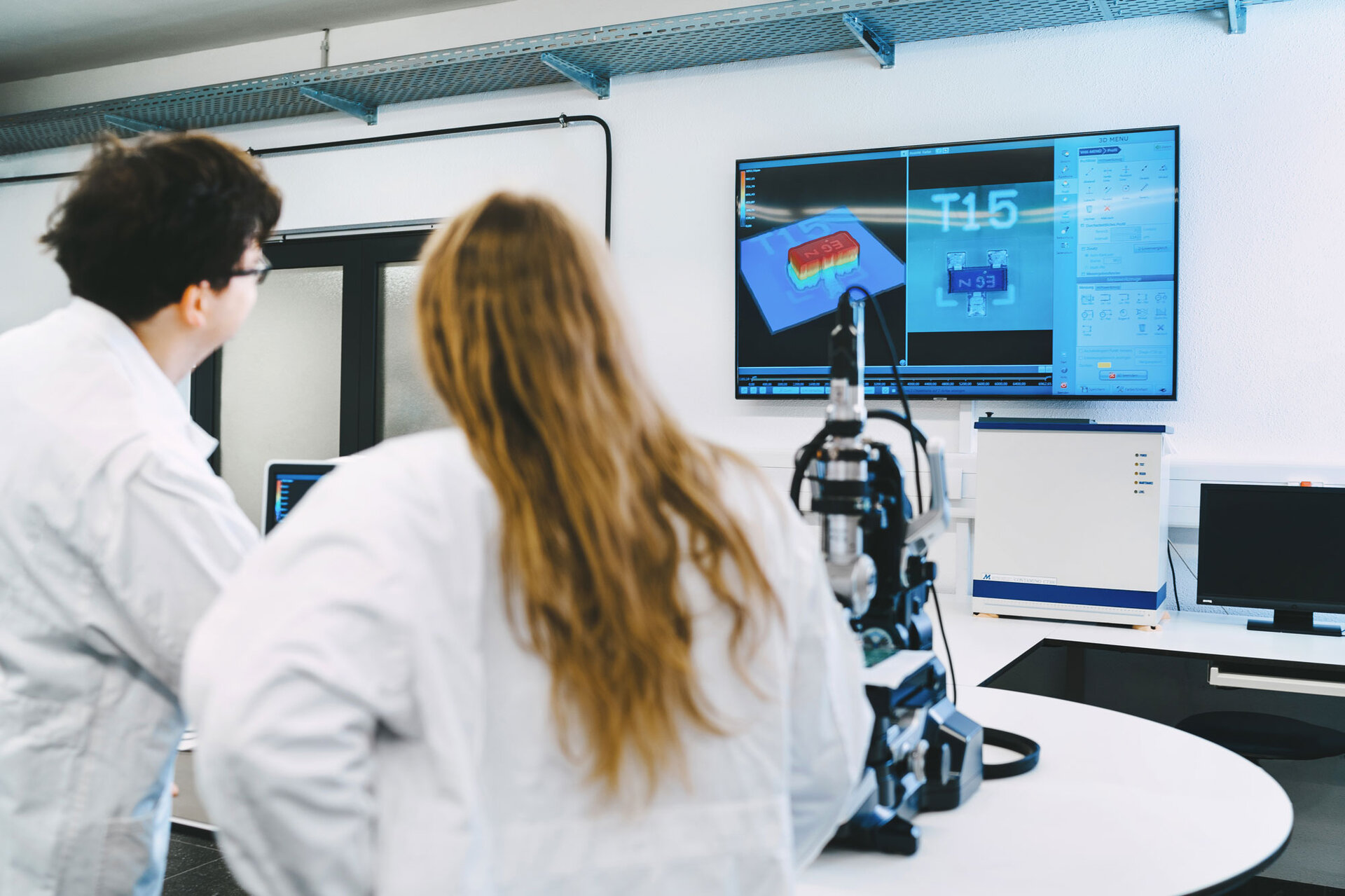

Contaminants such as flux residues or particles can significantly impair the functional reliability of electronic assemblies. Our purity analyses detect these residues with the highest precision – down to the micrometer level.

But we offer more than just data: Using state-of-the-art analytical methods, we assess the surface cleanliness of your assemblies. Our experts interpret the results and develop targeted measures to resolve existing issues and sustainably optimize your production processes.

Cleanliness analysisYour Benefits at a Glance

-

Verification of surface cleanliness/quality for internal and external audits

-

Compliance assurance with cleanliness requirements

-

Documented cleanliness for statistical process control

-

Ensures the coatability and bondability of your assembly

bath monitoringMaximum Efficiency and Safety for Your Cleaning Process

To ensure consistently high bath quality and optimal process reliability, ZESTRON provides dependable analyses. Based on the bath samples you send us, we define customized monitoring parameters according to standardized analytical procedures.

This allows you to maximize the service life of your cleaning agent while simultaneously reducing your process costs – efficiently and sustainably.

bath monitoringWhat We Offer

-

Analysis of bath samples using standardized ISO test methods

-

Technical reports including monitoring curves and intervention limits

-

Bath monitoring parameters specified for your application

When installing a new process with ZESTRON products, we also provide a free bath analysis service as part of your setup.