fact check After Rinsing Comes Drying: How to Ensure PCBAs are Truly Dry

time for a fact checkDrying in PCBA Cleaning

On the test bench: How to ensure PCBAs are truly dry.

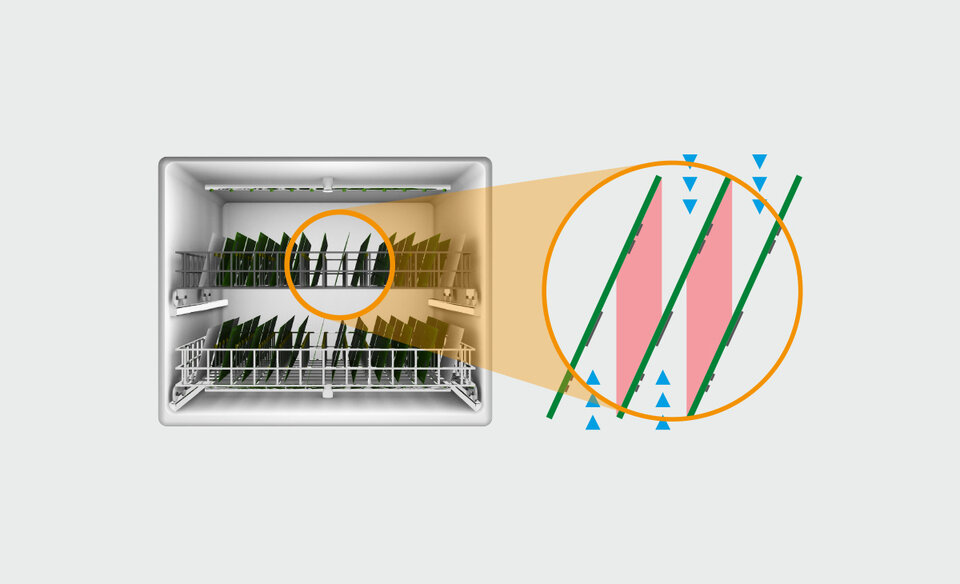

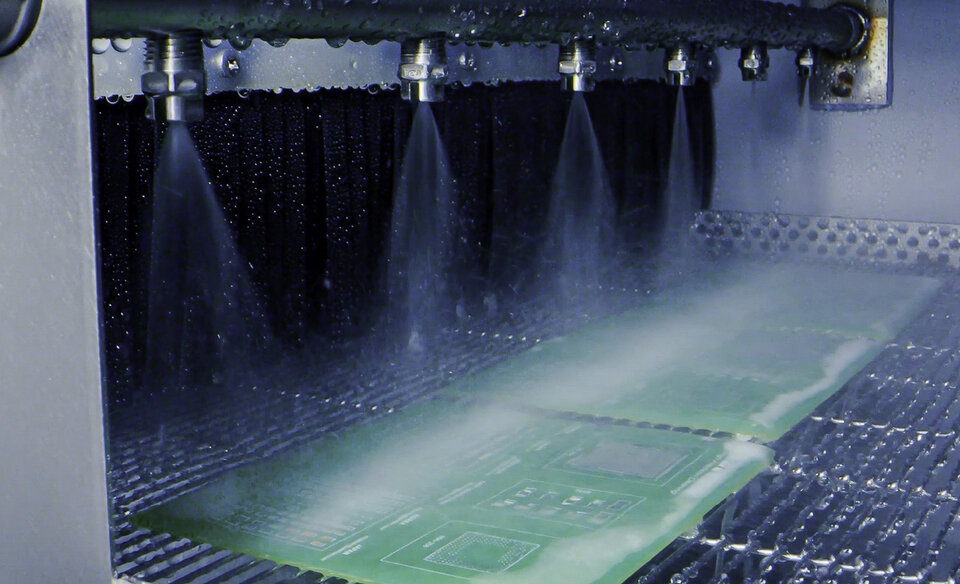

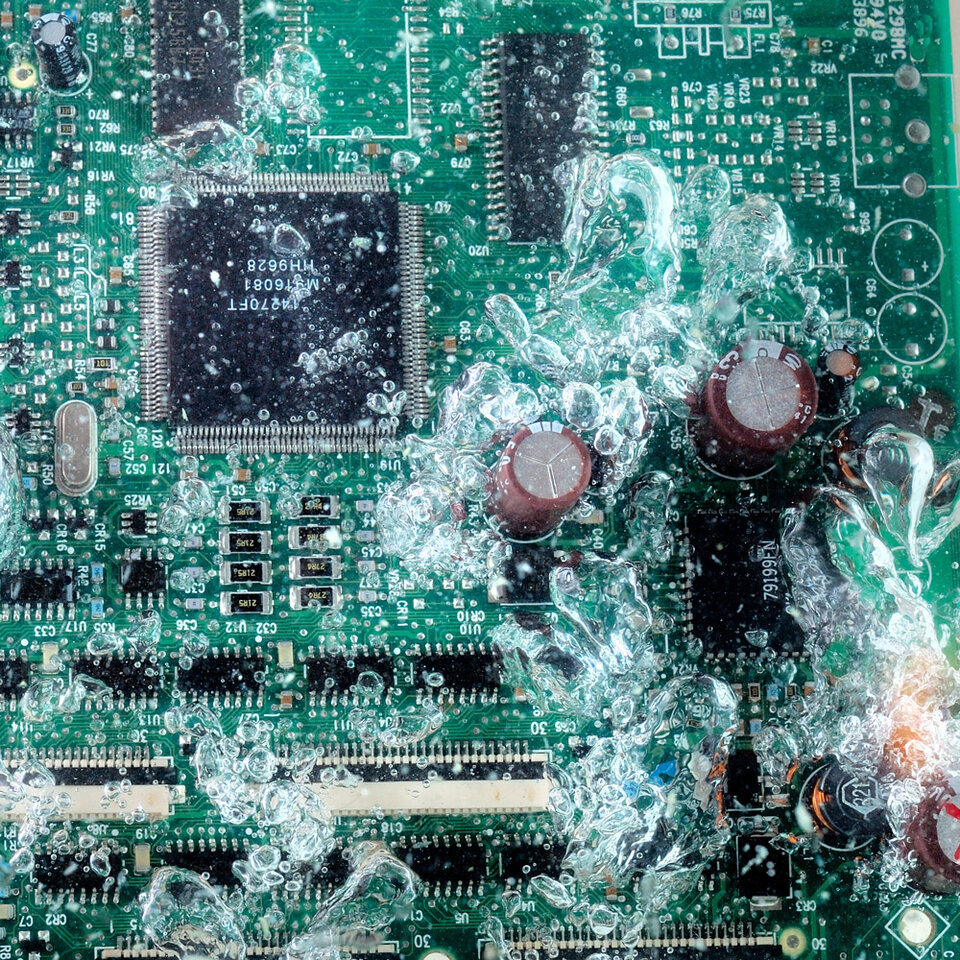

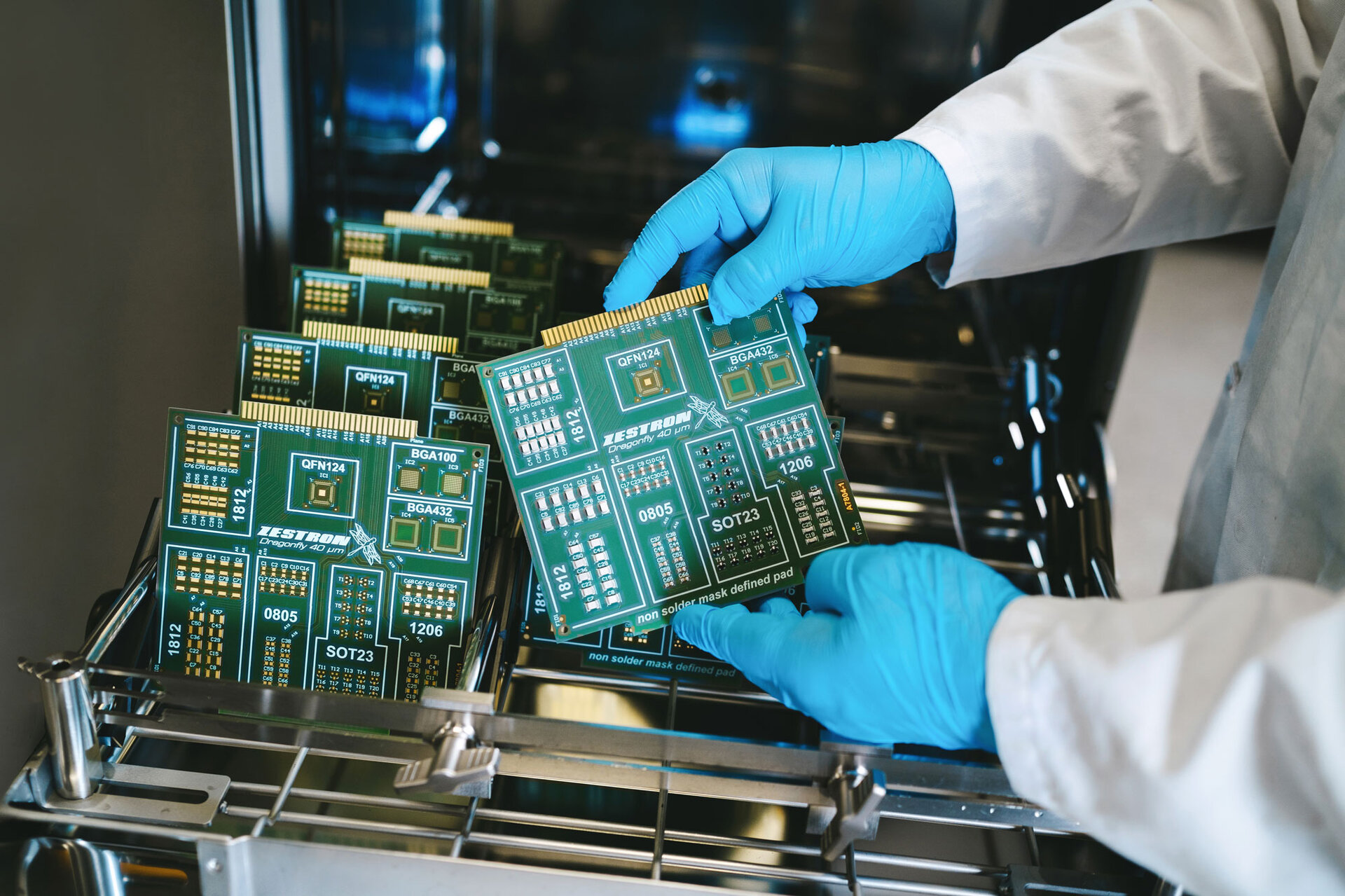

In principle, the cleaning process for electronic assemblies in batch systems works much like a dishwasher: first, flux residues are removed, then the PCBAs are rinsed and finally they are dried.

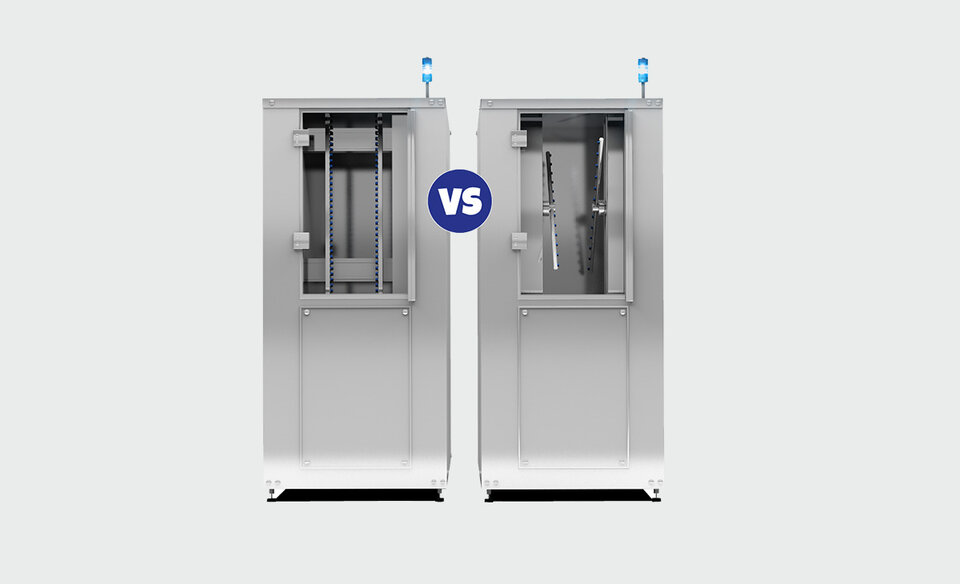

In inline systems, these three process steps occur sequentially in separate sections of the system. If all three steps are perfectly adjusted and synchronized, achieving optimal cleaning results becomes straightforward.

the fact checkThe Importance of Proper Drying

On the test bench: The key factors for drying PCBAs

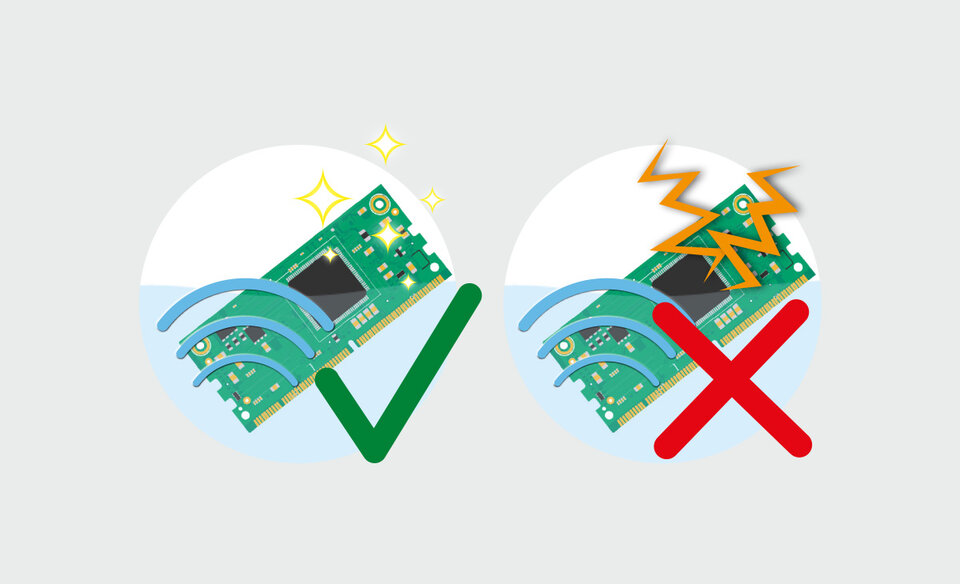

Drying plays a crucial role in the process and is key to ensuring the reliability of your PCBAs.

Several factors influence whether assemblies are thoroughly dried, including the geometry of the components and critical areas such as capillaries, plugs, or pinholes. The positioning of the assemblies in the product carrier also matters. Additionally, metal components with higher heat capacity typically dry faster than plastic parts with lower heat capacity—a phenomenon you may recognize from your home dishwasher.

However, how quickly assemblies are dry and thus the overall process time largely depends on the drying method used in the system.

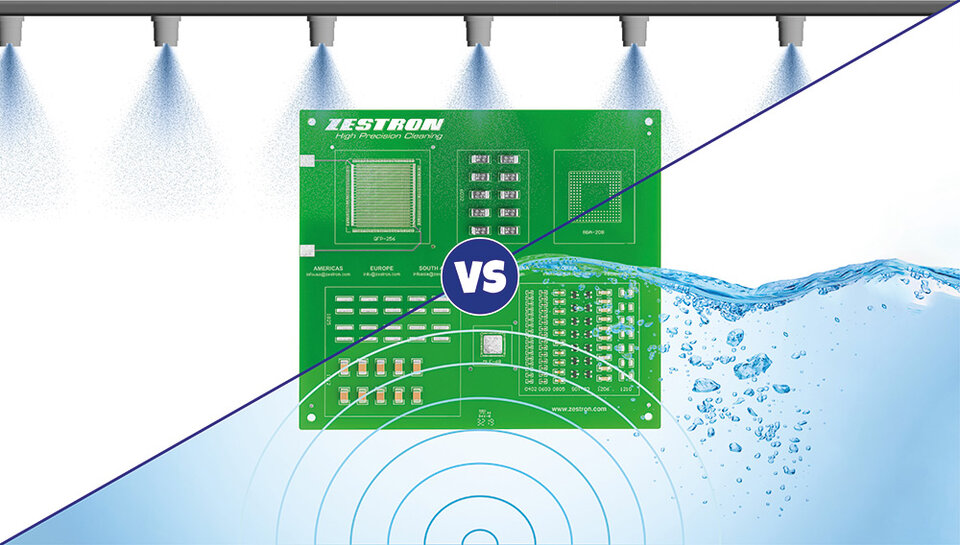

A Comparison of Common Drying Methods

Because not all drying is the same. Different systems work with different drying processes. Each process has specific characteristics that affect the process time, energy consumption and efficiency.

Common drying methods are:

-

Hot air: Hot air is blown into the system while moist air is extracted elsewhere (similar to a dishwasher or an oven)

-

Vacuum drying: The assemblies are preheated, then a vacuum is created, which lowers the boiling point of water. The moisture evaporates and is extracted.

-

Airknife: Powerful fan or directed air flow (warm or cold) that removes droplets from assemblies (similar to a car wash)

-

Infrared radiation: This method heats the assemblies directly and is often combined with hot air or vacuum drying (less frequently used process)

Each method has unique drying times, making them suitable for different throughput requirements. Drying time can significantly impact the overall process time, system selection, and energy consumption.

But how do the various drying processes differ? And are the assemblies really dry when they leave the system? Or is additional drying required?

Drying: Fact Check

We do a fact check on drying and have tested the various processes. Don't miss out on our well-founded test results. Find out:

-

The advantages and disadvantages of the individual drying methods in terms of time and throughput

-

The differences between drying in inline and single-chamber systems

-

How moisture is effectively removed from critical areas on assemblies

-

How to quickly and easily check whether assemblies are really dry