InsightsEfficient Solutions for Greater Sustainability and Cost Saving

Optimized DI Water Treatment: Cost Reduction Through Lower Disposal Costs.

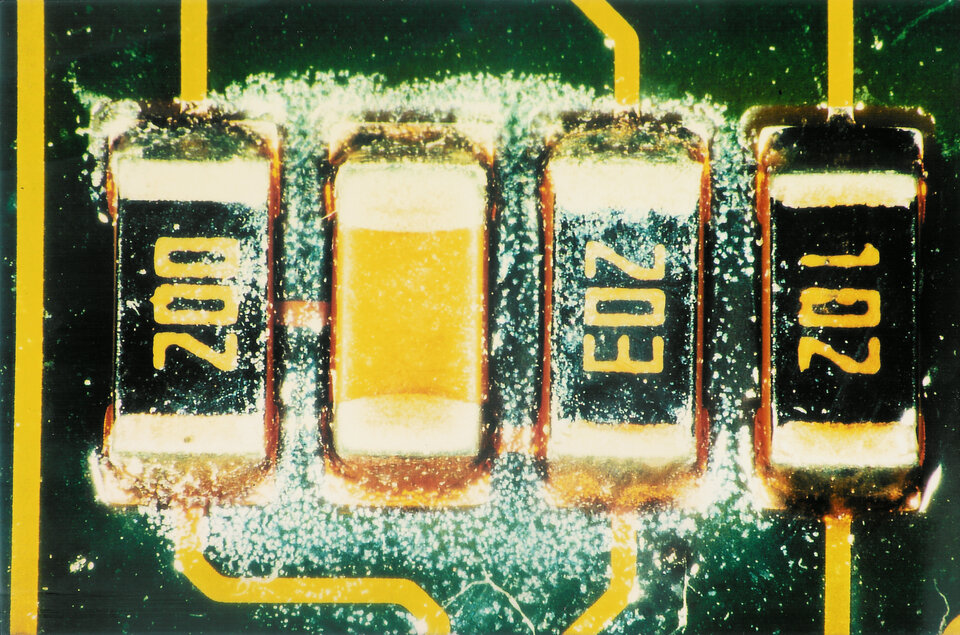

efficient PCBA CleaningSustainable Cost Reduction in Practice

Effective cleaning of electronic assemblies requires tailored solutions. In this practical example, we demonstrate how optimizing a cleaning process for an industrial customer not only enabled sustainable improvements but also delivered significant cost savings.

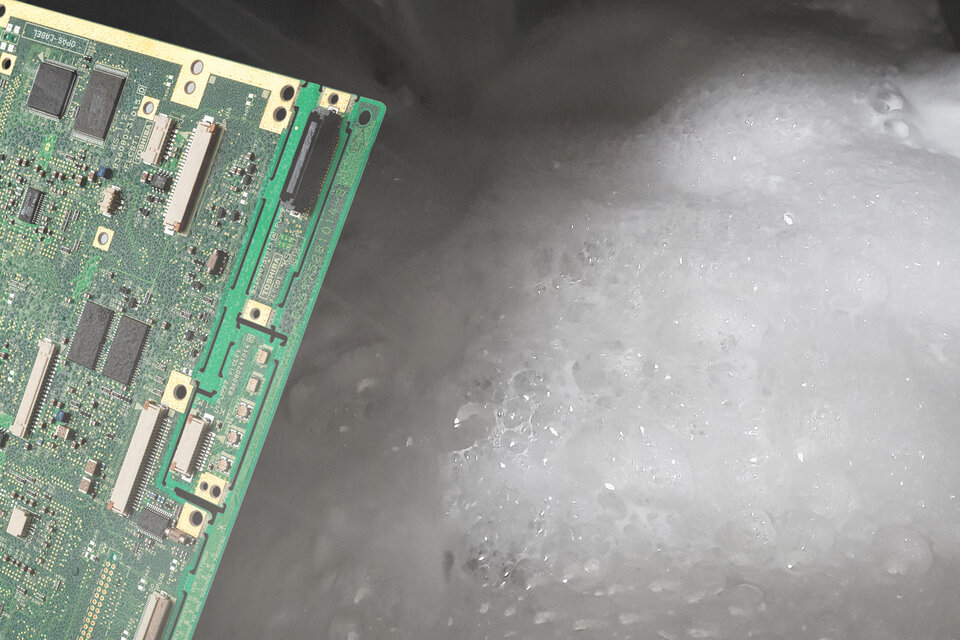

problemOutdated System and High Deionized Water Consumption

A customer in the industrial sector had two aging single-chamber spraying systems that also consumed a large amount of deionized water. In addition, there was no discharge permit, which forced the customer to regularly dispose of the used deionized water at a high cost: Perfect conditions for a sustainable and effective cleaning process look different - but we would not be the world market leader in the field of high-precision cleaning if we had not also found a suitable solution for this case.

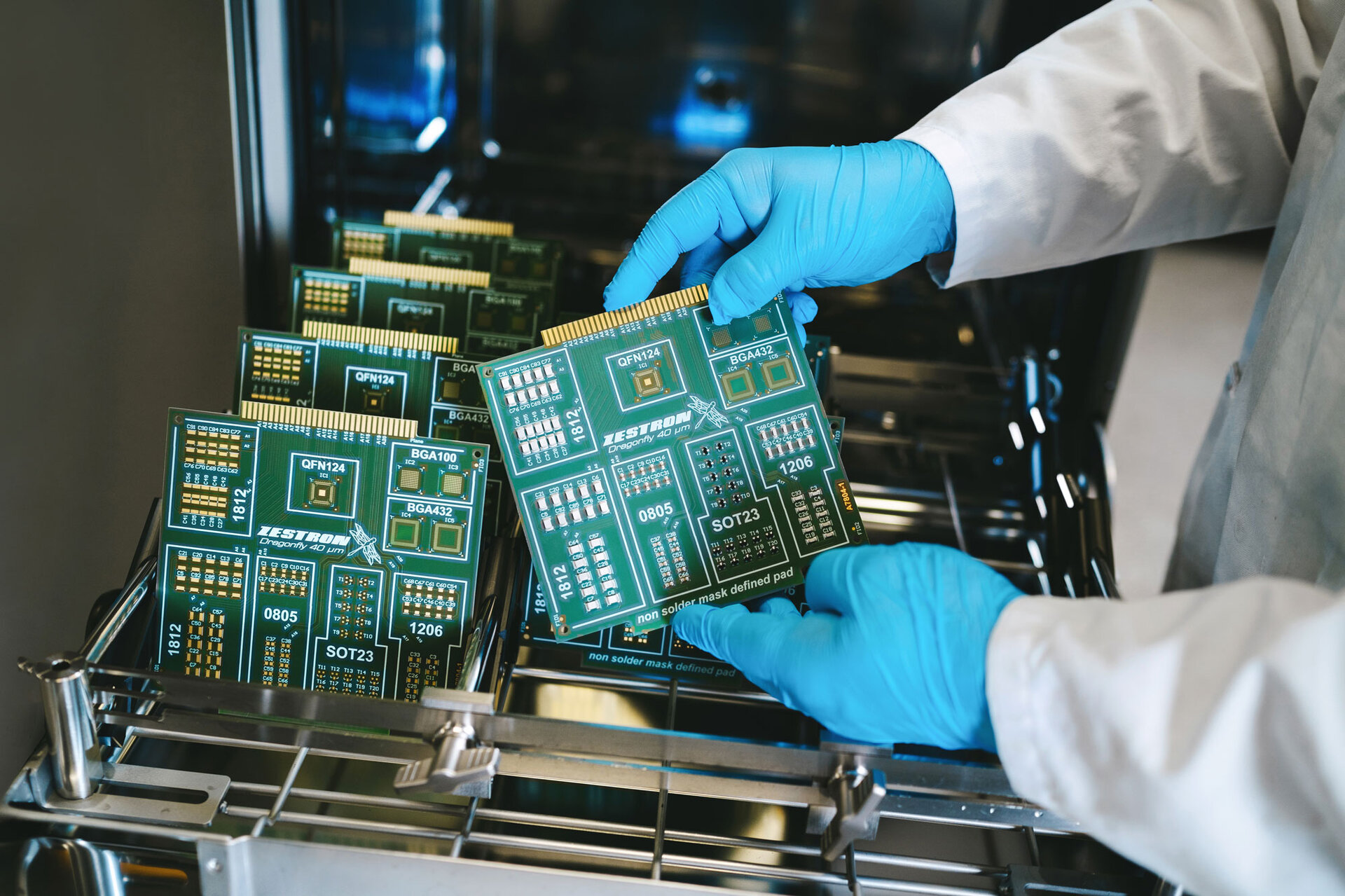

solutionSignificant Reduction of the Rinsing Medium

In constructive cooperation with the customer's plant partner, a concept was developed that brought several advantages at once. By reorganizing the process, our team managed to treat the deionized water several times, thus ensuring a significant reduction in amount of rinsing medium to be disposed. This resulted in several advantages for the customer: Not only did we succeed in making the entire cleaning process significantly more sustainable, but we also generated considerable cost savings for the customer.

zestron xpertiseFast Service, Reliable Solutions

All in all, a real success story - customer, machine partner and also the ZESTRON field service team had every reason to be happy:

And that is exactly what we here at ZESTRON want to stand for - finding custom-fit, individualized solutions, standing by our customers' side with expertise and active support, and thus ultimately meeting our own standards. Professional, fast and reliable!

Contact us – we will provide targeted support for your challenge