InsightsEnvironmentally Friendly Electronics Cleaning: Efficiency Meets Environmental Awareness

How can you ensure an environmentally friendly cleaning process for your electronics?

PCB CleaningDesigning an Environmentally Cleaning Process

How can you implement an eco-friendly cleaning process for your electronics? In a time where resource conservation, environmental protection, and energy efficiency are paramount, environmental awareness is increasingly important. This applies not only to large industries and private consumption but also to specialized areas such as cleaning electronic assemblies.

Especially in the electronics industry, environmentally friendly cleaning methods not only help reduce environmental impacts but also increase the longevity and reliability of electronic devices. Innovative methods and technologies are being developed to make the cleaning process more efficient and eco-friendly.

PCB CleaningClean Electronics, Clean Environment: An Overview of Measures

To design the cleaning process for electronic assemblies to be more environmentally friendly, several effective approaches can be taken:

-

When purchasing cleaning systems, you can focus on an environmentally conscious concept for both the cleaning and rinsing stages.

Adsorbers for heavy metal filtration: Such adsorbers filter heavy metals from the cleaning bath, extending its service life

Closed-loop system: A closed-loop system enables a wastewater-free rinsing process. -

Choosing a water-based cleaner: an environmentally friendly and biodegradable alternative to solvent-based cleaners

-

Reducing process temperatures: Lower temperatures reduce energy consumption for heating and supplying cleaning media.

environmentally friendly PCB CleaningMeasures in Focus

The following describes these measures in detail to showcase their specific advantages and applications.

adsorbers Heavy Metal Removal with Adsorbers

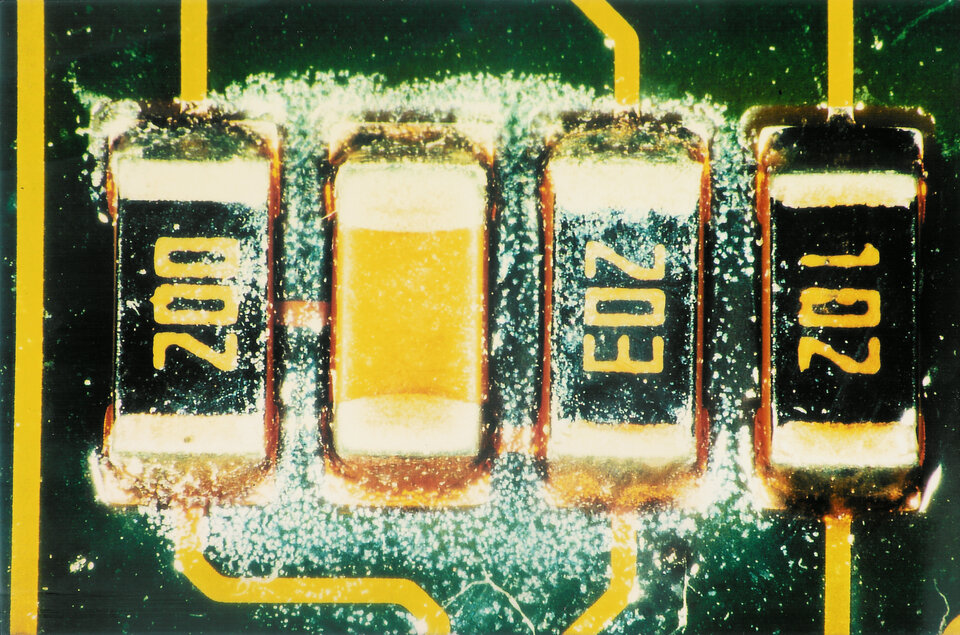

The cleaning agents used in the cleaning process remove particles and flux residues from electronic assemblies. These contaminants end up in the cleaning bath. Additionally, various metal ions dissolve in the cleaner and rinse water from metal surfaces such as solder pads, solder deposits, connections, and heat sinks.

High throughput can lead to critical and environmentally hazardous ion concentrations in a systems circulation over time. An adsorber integrated into the cleaning circulation can selectively filter out heavy metal ions such as copper, tin, lead, iron, zinc, nickel, antimony, or bismuth. Longer bath lifetimes can thus be achieved.

Cleaning Systems Resource Efficiency through Closed-Loop Systems

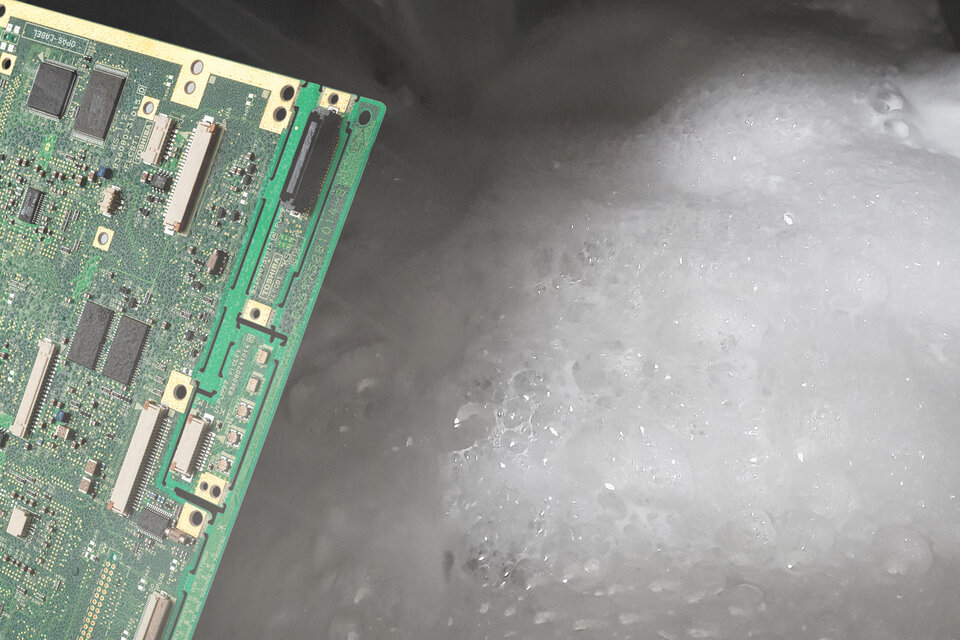

In cleaning electronic assemblies, the choice of rinsing system plays a crucial role in efficiency and environmental friendliness. There are two main types: open-loop and closed-loop systems.

In an open-loop system, the rinse water is discarded after each rinse and directed to the sewage system, requiring special permits and leading to high water consumption and wastewater volume.

Closed-loop systems offer a sustainable and cost-saving alternative. Here, the used rinse water is recycled within the system. Using mixed bed resin and activated carbon cartridges, organic contaminants and salts are effectively removed. The result is an almost wastewater-free process that protects the environment and reduces operating costs.

Our engineers are ready to help you develop an eco-friendly process tailored to your needs.

cleaning chemistry Eco-Friendly Electronics Cleaners

Water-based cleaning processes have not only replaced antiquated flammable solvents which were used due to a lack of alternatives but have also become the new standard in recent years. The VIGON© products with innovative MPC® technology are your guarantee for environmentally friendly assembly cleaning:

-

Halogen-free: Water-based cleaners contain no halogens, which could be harmful to the environment.

-

Low VOC content: Water-based cleaners have a low volatile organic compound (VOC) content.

-

Excellent bath lifetimes: Thanks to their efficient filterability, water-based cleaners can be used longer, supporting resource conservation and reducing ongoing costs.

-

Low operating temperatures: Cleaners based on MPC technology can perform at their best from a temperature of 40°C.

-

No fire hazard: Water-based cleaners have no flash point, making them safer to handle.

When selecting the appropriate cleaning medium, consider not only obvious aspects like material compatibility and the cleanliness result at the lowest possible process temperatures but also the longest possible usability of the cleaner. This way, you protect the environment and reduce your costs simultaneously.