Dendrites in Power Modules: The Silent Risk with Costly Consequences

Understanding dendrite formation, preventing failures: We analyze the causes and develop effective protection strategies together with you.

Failure Causes in power modulesInvisible Source of Failure: Dendrites as Root Cause

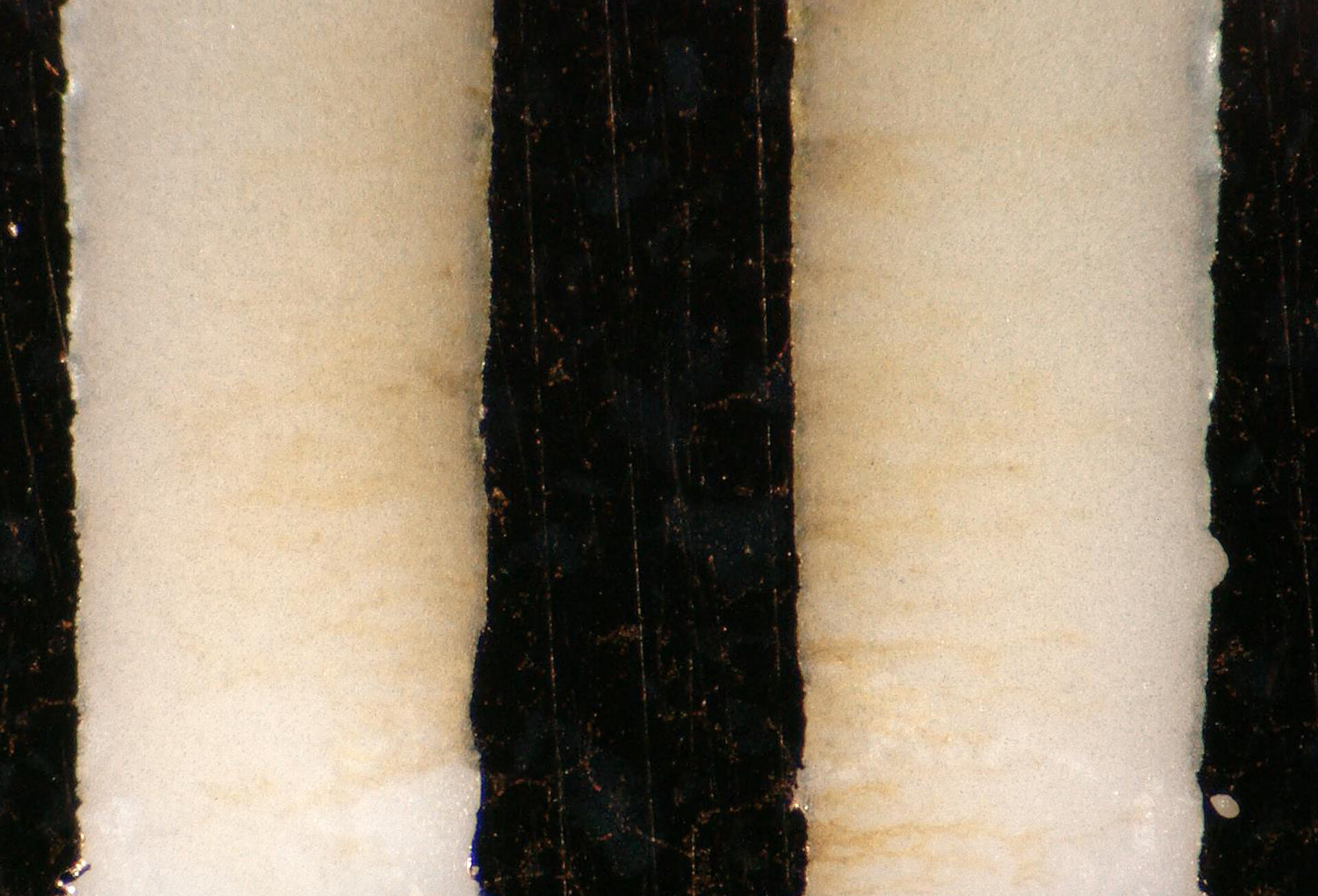

Dendrite formation is among the most difficult failure mechanisms to detect in power modules. Especially in applications with high current densities – such as industrial power supplies, e-mobility, or fast-charging stations – dendritic structures can trigger sudden system shutdowns due to excessive reverse leakage currents.

What may seem like a microchemical phenomenon can have severe practical consequences: production stoppages, high return rates, and repair costs reaching five figures. The failure often remains puzzling for a long time, as dendrites usually do not cause thermal damage but rather lead to an abrupt shutdown of the assembly.

understanding the cuases What Causes Dendrite Formation in Power Modules?

Dendrite formation is not a random event but the result of complex interactions between materials, electric fields, and environmental influences. It rarely stems from a single trigger and typically arises through the interplay of multiple mechanisms such as:

-

Electrochemical migration (ECM): Ionic transport processes intensified by electric fields and humidity.

-

Anodic migration phenomenon (AMP): Local dissolution and deposition processes that can result in metallic growths.

-

Moisture-induced leakage currents: Hygroscopic residues promote leakage paths and accelerate the development of conductive structures.

-

Localized partial discharges: Micro-discharges at interfaces weaken insulation distances and act as catalysts for dendritic growth.

In power modules, dendrite formation strongly depends on the combination of material properties, electric field distribution, and climatic operating conditions. Even minimal amounts of flux or process residues, in conjunction with humidity or corrosive gases, can create a critical risk.

In industrial applications, these climatic influences are rarely reproducible or directly measurable. Therefore, it is essential to systematically capture them during failure analysis—through optical inspection, SEM/EDX analysis, or long-term testing under realistic climatic conditions. Only by doing so can the root causes be clearly identified, and compliance with intended use be demonstrated transparently to OEMs, customers, and suppliers.

in-depth analysis & targeted preventionPractical Strategies to Prevent Dendrite Formation

Experiencing dendrite-related issues or aiming to eliminate the risk of failures in your power modules from the outset?

Our experts support you with proven, practice-oriented methods for analysis, evaluation, and prevention, including:

-

Ion chromatography to identify hygroscopic and conductive residues that can trigger leakage currents and ECM processes.

-

SEM/EDX analysis for structural and chemical characterization of dendritic deposits — from growth direction to material composition.

-

Impedance spectroscopy to assess moisture-resistant coatings and protective measures.

Even before product deployment, we simulate realistic climatic conditions (humidity, corrosive gases, partial discharges) to evaluate the moisture resistance of your power modules. This enables early detection and targeted elimination of critical weak points.

The protection strategies developed are individually tailored to your applications, environmental conditions, and production processes — ensuring transparent reliability verification of your modules toward OEMs, customers, and suppliers.

InsightDendrites, creepage paths, and deposits on electronic assemblies – all consequences of electrochemical migration?

What exactly is behind electrochemical migration, and how does it differ from the anodic migration phenomenon (AMP)? Using practical examples, we illustrate how dendrites form, what distinguishes copper from tin dendrites, and how these mechanisms can be reliably detected.

Assistance ModuleFailure Analysis for Corrosion and Leakage Current

Are your power modules at risk due to corrosion, leakage currents, or dendrite formation?

Our specialized assistance module helps detect weak points at an early stage and develop sustainable strategies to ensure stable performance and reliable power electronics.

whitepaper collectionMoisture and Material-Induced Failure Mechanisms in Power Electronics

Power electronics in wind turbines and electric mobility are often exposed to harsh environmental conditions such as humidity, which can significantly impact the reliability and service life of modules. At low voltages, failures are typically caused by electrochemical migration (ECM), whereas in high-voltage applications, an anodic–cathodic migration phenomenon (AMP) becomes predominant.

This white paper explains, through case studies, the specific conditions under which this transition between failure mechanisms occurs.