Comprehensive Guide to Effective Cleaning Processes

Main influencing factors in achieving an desirable cleaning outcome.

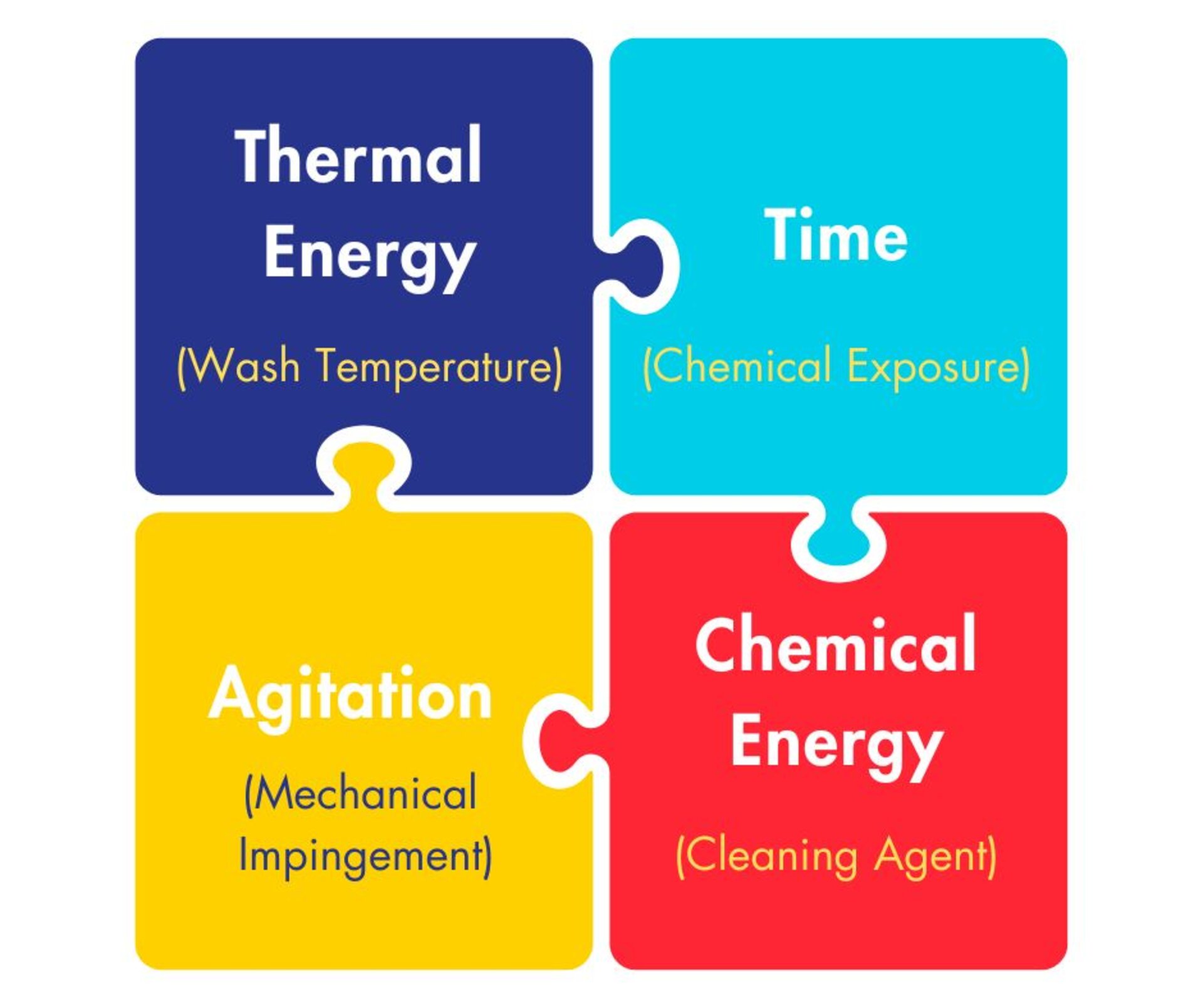

CLEANING PROCESSWhat are the factors influencing the overall cleaning effectiveness?

The flux residues after soldering create a cleaning challenge, particularly underneath low-profile components. Therefore, it is important to consider several factors when implementing a cleaning process to ensure its effectiveness.

The four major influencing factors are thermal energy (temperature), mechanical energy (equipment), chemical energy (cleaning agent), and time (chemistry exposure time/cleaning time).

1. Thermal Energy - Wash Temperature

Temperature affects the properties of the flux as well as the efficiency of the cleaning agent used. In general, you get better and faster cleaning reactions at a higher temperature compared to when at a lower temperature. It could also potentially reduce the cleaning time (cycle time) when the residues are more easily removed.

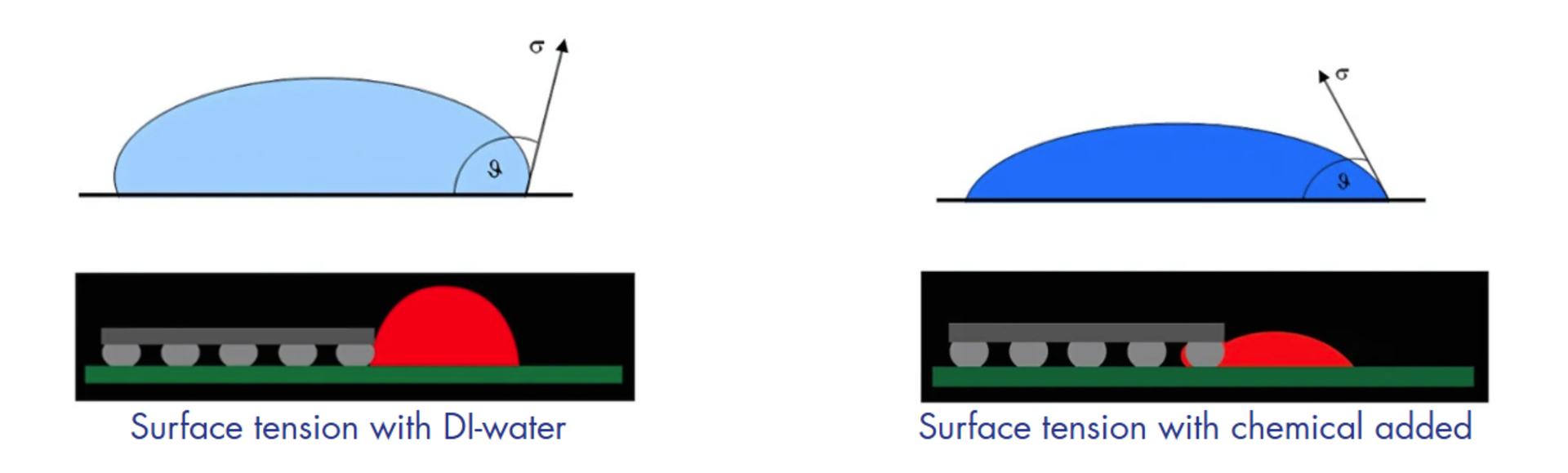

Also, the increased temperature reduces the surface tension of the cleaning agent, which enables it to flow easily under low-profile components.

2. Agitation - Mechanical Impingement

Mechanical impingement, or the so-called cleaning equipment configuration, is the physical attrition of removing residues or contamination from a package surface. Different equipment needs to be evaluated for the suitability and effectiveness towards certain contaminations, process type and the cleaning agent used. The most commonly known mechanical / equipment used in a cleaning process includes immersion with pressure flooding, ultrasonic cleaning, and spray processes in both inline and batch systems.

Spray-in-air cleaning systems are typically used in the electronics industry for high-volume production lines, which combine the cleaning agent with the physical impact of the spray to effectively remove the flux residues and other contamination from the product surface and from underneath the small gaps. This technology is commonly employed in semiconductor advanced packaging cleaning processes.

With Zestron’s machine test service in our local technical centre, it is possible to explore various combinations of cleaning systems suitable for your specific requirements in SMT, power electronics, and packages cleaning, as well as conducting cleaning tests.

3. Chemical Energy - Cleaning Agent

Chemical energy is the cleaning agent that should be considered in the cleaning process. The cleaning agent is an essential factor to dissolve the residues or contaminants from the substrates and should be recommended by the chemical supplier to ensure the product is effective for the specific flux residues involved in the process, as well as the chosen cleaning system.

The most commonly used cleaning agents for electronic boards and packages are solvent-based and water-based, like Micro Phase Cleaning (MPC®). The chemical supplier can assist in evaluating the compatibility of the chemical with the materials used and the contaminants to remove from the product or package assembly.

More about CLEANING AGENT TYPESmore about CLEAner technologiesThe below graphic shows the comparison of the cleaning effect where adding a small amount of cleaning agent into the water can reduce the surface tension of water and allow better penetration into small gaps and ensuring better cleaning results.

4. Time - Cleaning Duration

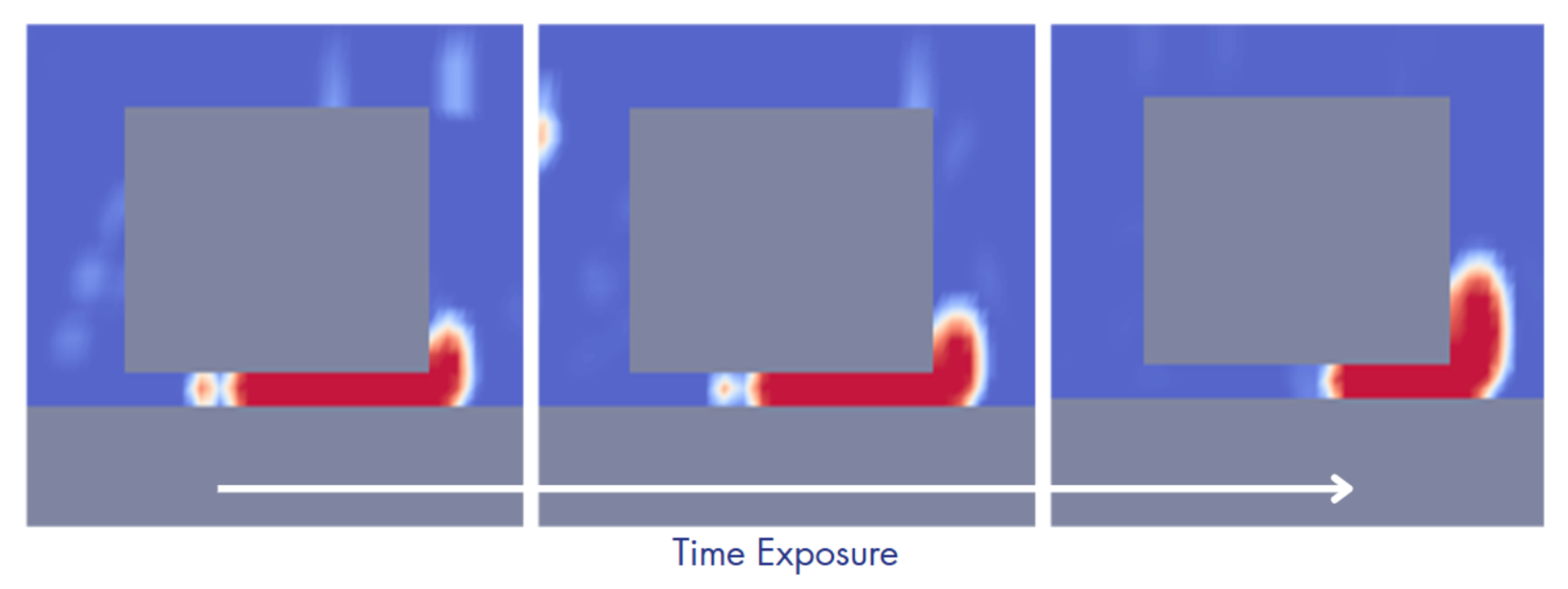

It is always a key point for the manufacturing process to minimise the process cycle time to increase the production throughput. As such, the results of the cleaning process depend greatly on the amount of cleaning time the parts were exposed to the cleaning agent. The longer the cleaning exposure time, the more contamination will be removed.

In an ideal condition, cleaning would take as long as necessary to ensure the parts are well cleaned, especially for low standoff gap components, when it requires longer cleaning time to ensure creation of a flow channel to remove the residues underneath it. However, the long cleaning time would also affect the material compatibility.

Therefore, for a successful desired cleaning process, engineers must play around with the key parameters to ensure the flux residues are completely removed within the shortest process time while offering the desired outcome.

Cleaning processEach factor correlates to achieve an efficient cleaning process.

In short, the four factors correlate to achieve an efficient cleaning process. The types of cleaning agents, application concentration, chemistry exposure time, and temperature are critical parameters that will influence the effectiveness of cleaning. Users need to understand the influences and make necessary adjustments from time to time.

Check out our whitepaper for more details about the strategies to an optimal cleaning: Critical Cleaning Requirements to Overcome Advanced Packaging Defluxing Challenges

Request for a cleaning trial for our application experts to evaluate your cleaning process for improvement and necessary adjustments to achieve your ideal outcome.

Talk To Us