InsightsElectrochemical Migration: Tracking Power Module Failures

Case Study: Assemblies of Dishwashers Fail Quality Inspection

electrochemical migrationPreventing Failures of Power Modules in Dishwashers

Moisture and salts that occur in household dishwashers pose a significant technical challenge for manufacturers. If these factors are not adequately addressed, they can cause corrosion and electrochemical migration on the electronic power modules.

These failure mechanisms not only lead to increased repair costs and increased warranty claims but can also trigger delivery delays and cost-intensive recalls.

Therefore, it is decisive to deal intensively with these sources of failure already in pre-series production. Our R&S experts support you with their many years of experience in evaluating faults to minimize potential failures and reduce associated costs.

Case StudyFailure of a Dishwasher Power Module

The following case study analyzes in detail the challenges faced by a manufacturer in the dishwasher industry, in particular regarding a failure in the power module. Our R&S experts have developed a tailored solution approach in close collaboration to effectively assist the manufacturer in addressing these technical challenges.

problem statementDendrite Formation on Assemblies

Our client experienced increasing issues with newly installed power modules, especially during the operation test at the end of the production line.

Failures occurred more frequently after qualification tests for temperature shock and cyclic moisture-heat stress.

The problem manifested in significant dendrite growth originating from the through-hole solder joint and the exposed copper trace on the assembly.

Due to difficulties in explaining the failure, the company turned to our R&S expert team.

root cause analysisElectrochemical Migration the Reason?

Based on the failures described by the manufacturer, our expert team formulated the hypothesis for the cause of failure:

Elektrochemische Migration (ECM), ausgelöst durch einen erheblichen Grad der Verschmutzung in Kombination mit intensiven Einflüssen von Temperatur und Feuchtigkeit.

fault diagnosisIn-Depth Failure Analysis

To verify the assumption of electrochemical migration, our team initiated selected failure analyses:

01 | Visual Inspection Under Microscope

Examination of residue distribution on the solder mask:

-

Large areas of contamination detected

-

Metallic structures via interference contrast visible

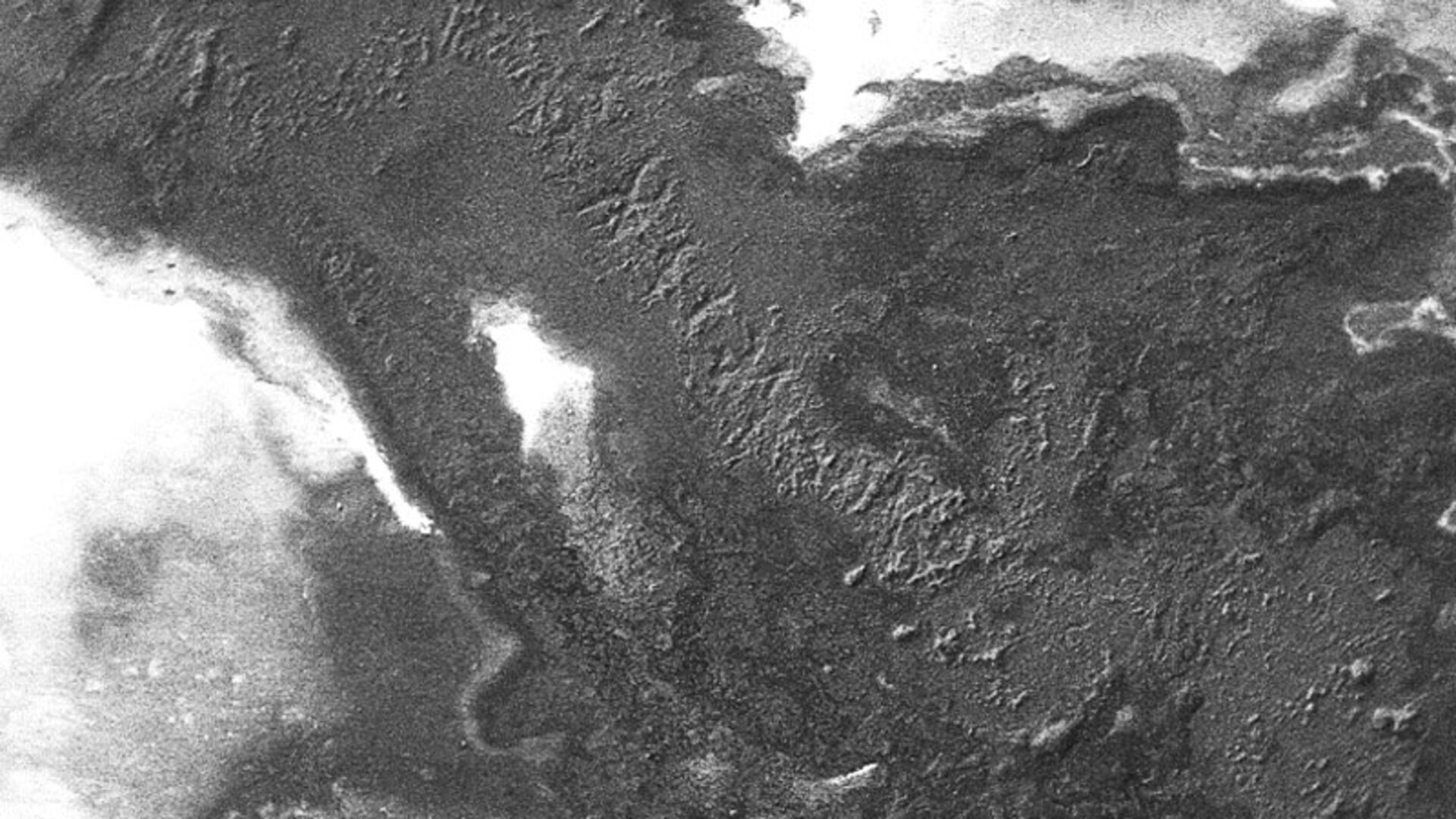

02| SEM/EDX Examination

Confirmation of the hypothesis "electrochemical migration":

-

Dendritic structures - tin material

-

Significant amount of organic residues

03| ZESTRON Flux Test and ZESTRON Resin Test

Test methods for residue analysis:

-

Identification of exposed activators

-

Confirmation of organic residues through blue coloration

-

Detection of resin residues

-

Confirmation of resin residues through yellow coloration

04| Ion Chromatography

Identification and quantification of ionic impurities:

-

Significant amounts of bromide, chloride, succinate, and sodium measured

-

Exceeded limits according to IPC-CH-65B

-

Hygroscopic substances on the assembly backside promote creepage currents and dew formation triggering electrochemical migration.

interpretationHolistic Failure Interpretation

The available analysis results indicate that specific humidity-heat conditions during functional testing favored dew formation.

It can be assumed that the failure in the dishwasher's power module is due to electrochemical migration. This is manifested by the growth of dendrites on the assembly surface, caused by defects in the solder mask and the presence of strong hygroscopic contamination.

The interpretation of the failure by the R&S team goes beyond the purely analytical level. This enables not only the diagnosis of the failure, but also the derivation of solution approaches. These approaches offer our customers concrete measures for failure prevention.

solution approachesEfficient Prevention of Electrochemical Migration

By precisely interpretation of the results, our team was able to derive effective solution approaches to significantly reduce the risk of electrochemical migration in the dishwasher's power modules.

These customer-oriented solution approaches were developed not only to eliminate existing weak points but also to implement preventive measures to avoid failures in the future.

Recommended measures and solution approaches:

-

Reviewing current power modules for potential defects in the solder mask. The aim is to ensure that there are no deficiencies or incomplete wetted solder pads..

-

Instruction to order power modules without defects. This could be ensured through precise pcb specifications and quality standards.

-

Improvement of the selective soldering process to ensure minimum amount of flux and deactivation of the residues. This could include the adjustment of parameters, monitoring techniques or training for the manufacturing staff.

These developed solution approaches were discussed in detail with the customer. Our team was actively involved in the implementation of the discussed measures and provided concrete support.

Your Partner for reliable assembliesExperiencing Inexplicable Failures of Your Power Modules?

whitepaper-collectionUnderstanding and Preventing Electrochemical Migration

Our free technical articles provide in-depth answers on the causes, mechanisms, and protective measures against ECM – concise and practice-oriented.