Understand and Assess Risks on Electronic Assemblies

Our Experienced R&S Team Supports you on this Path.

Avoiding and Repairing Damage - A Journey Similar to Crossing the Alps

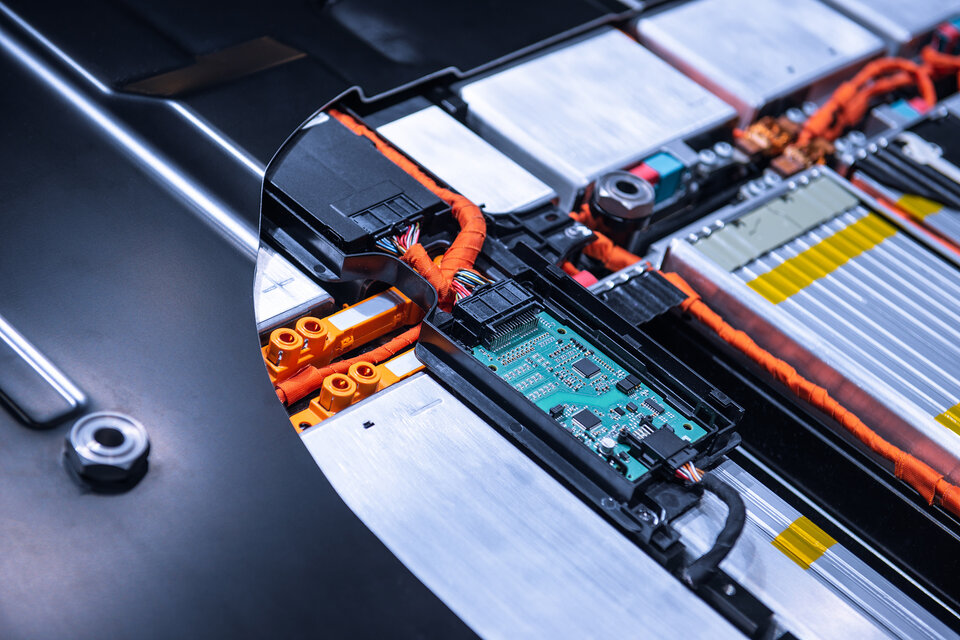

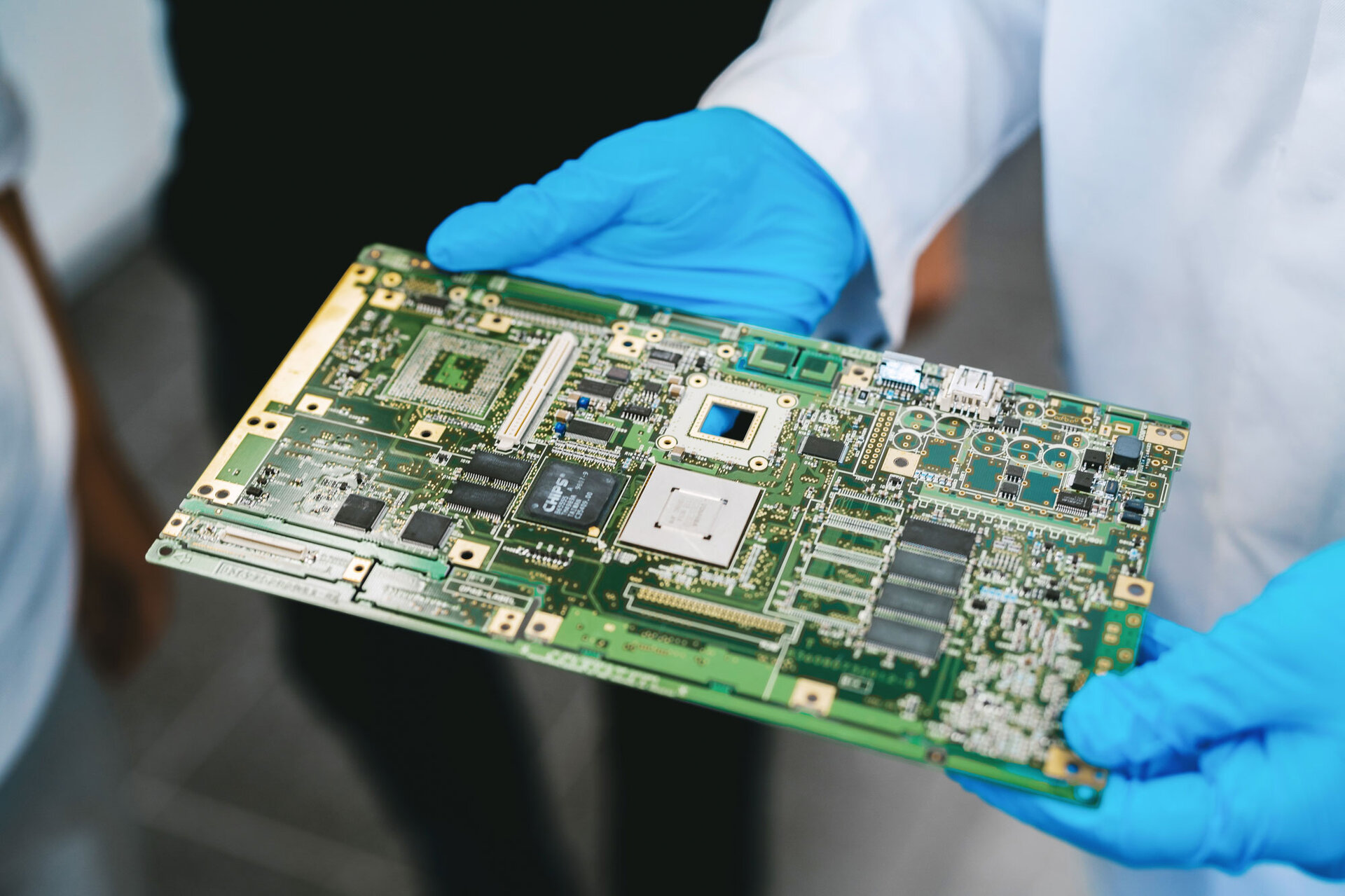

Our Reliability & Surfaces Team (R&S) supports you across the entire value chain of electronics manufacturing. Whether risk assessment or damage analysis - we develop concrete solutions so that you can produce reliable and moisture-resistant assemblies.

YOUR ALPS Ensure the Reliability of Your Assembly

Producing moisture-resistant, reliable assemblies with a low risk of failure sometimes seems like crossing the Alps: a winding, steep path full of stumbling blocks, obstacles and unexpected turns. Our experienced R&S team accompanies and supports you on this path.

In Technology Coaching, the team preventively assesses the failure risk of assemblies, analyses failures during validation stress tests and goes into root cause analysis in the event of damage in the field. In doing so, it uses modern analytics, looks at your problem holistically and in the system context, and develops concrete, implementable solutions.

COACHING OFFERTechnology Coaching: Your Pathway to Reliability Step by Step

OUR ALPSThe Surface of Your Electronic Assemblies

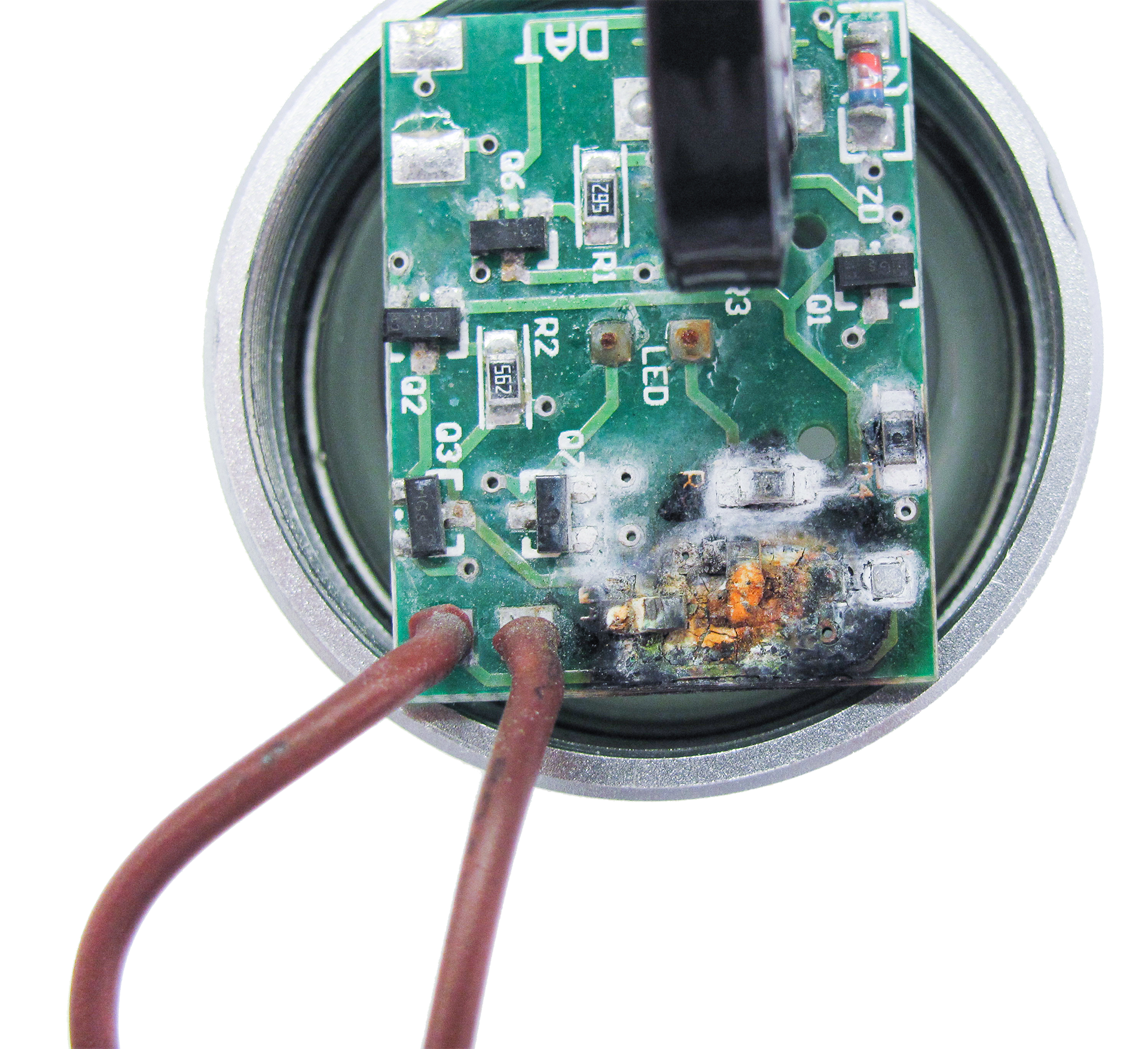

Various processes on the surface of assemblies can impair their reliability. Ionic contamination or insufficient coatings in combination with moisture, but also particles (technical cleanliness) are often triggers for malfunctions. Typical failure mechanisms in this context are electrochemical migration, leakage current or a thermal event. For the R&S team, the clear identification of these mechanisms is the key to remedial action.