InsightsSafety and Quality Standards in Automotive Manufacturing

Avoid costly recalls and secure your production line with a tailored quality solution.

failure analysisHighest Quality Standards in Automotive Manufacturing: Effectively Preventing Recalls

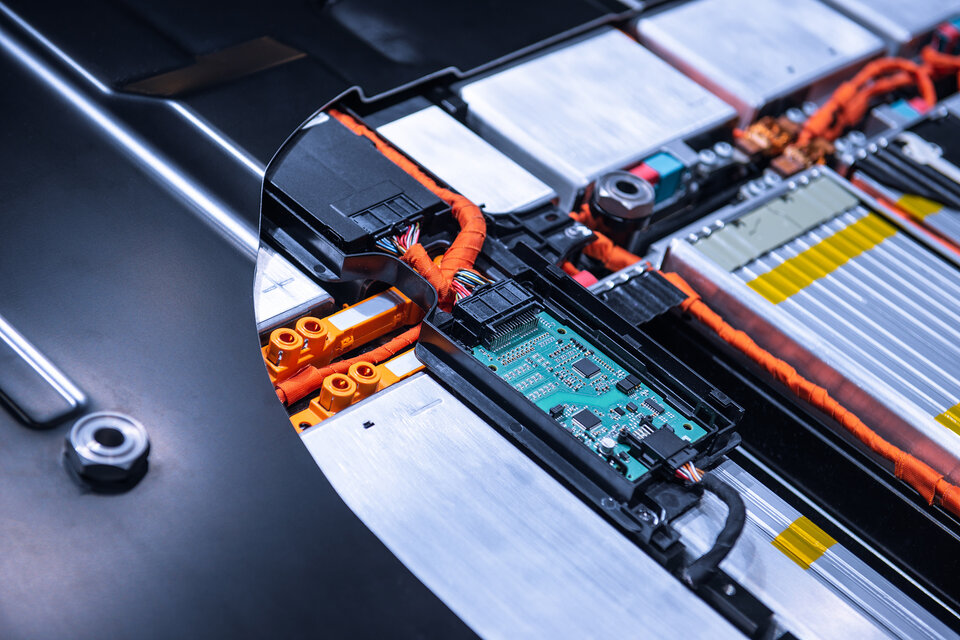

In the automotive industry, adhering to the highest quality standards and avoiding costly recalls are top priorities. Reliability is particularly crucial for electronic assemblies, as the safety of vehicle occupants is at stake.

Sudden issues in this area are not only frustrating but can also have severe consequences, such as complete delivery halts and claims for damages.

challenge Climate Stress Test Reveals Potential Delivery Ban

A leading automotive manufacturer discovered hidden defects in an electronic assembly during a routine climate stress test. A prompt complaint followed, and the supplier in question was given a strict deadline to resolve the issues. Failure to do so would result in a delivery ban, potentially jeopardizing the entire production chain.

The automotive manufacturer suspected inadequate insulation on the assembly surface and demanded a significant improvement in moisture resistance.

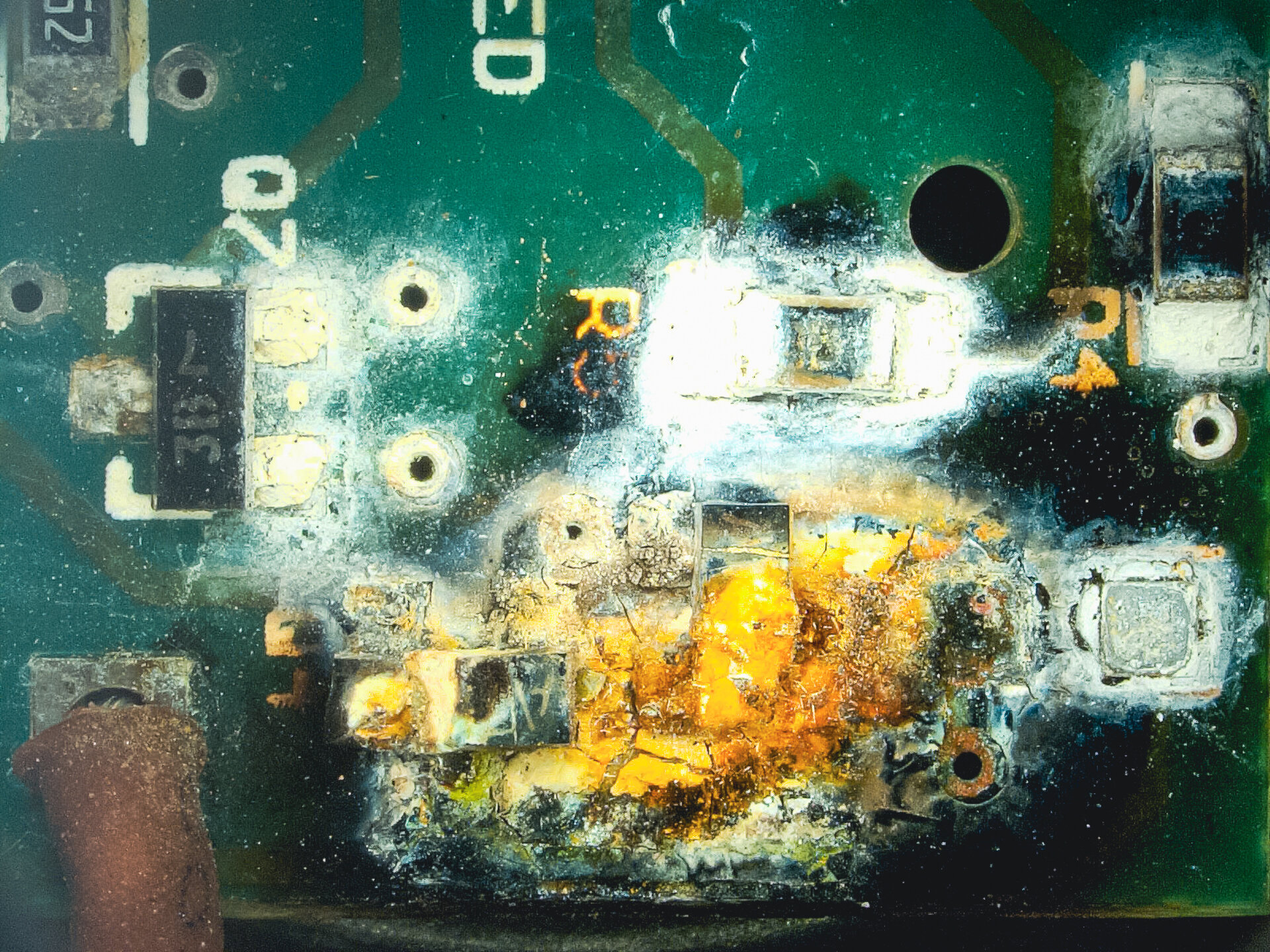

analysis Thermal Event as a Potential Hazard

To meet the required improvements, the supplier sought the expertise of ZESTRON's R&D specialists. While they determined that the anomalies were in line with the delivery specifications, the automotive manufacturer still perceived a significant risk of a potential "thermal event." The possibility of a fire hazard within the vehicle could not be ruled out.

solution Standards Specialist Secures the Production Chain

With the help of a standards specialist from ZESTRON, the risk of a "thermal event" was assessed and neutralized. The expert developed new purchasing specifications for the electronic components (PCBs), enhancing fire resistance and dielectric strength.

These new specifications fully addressed the automotive manufacturer's concerns about fire hazards, allowing production to continue without interruptions.

What Challenge Can We Help You With?

whitepaper-collectionProcedure for Estimating the Lifetime of a PCB under Humid Climate Exposure

In the future, the calculation methods for climatic assembly reliability may become as important for test time reduction and pre-optimization as the current methods for calculating thermal or mechanical reliability.