InsightsEnsuring the Technical Cleanliness of High-Voltage Components for Maximum Efficiency

Risk Analysis: Can Technical Cleanliness Be Ensured Without the Intermediate Step of Electronics Cleaning?

risk assessmentIs Technical Cleanliness Ensured?

Sensitive high-voltage components can be compromised by particulate contamination from previous process steps. To minimize this risk, many production lines incorporate additional cleaning systems for particle removal to maintain the technical cleanliness of high-voltage components.

This was the case for our customer, who implemented an extra cleaning step before applying the protective coating to reduce residual contamination risk as much as possible. However, since the protective coating also serves as an insulating material and could potentially provide sufficient protection, the question arose whether this additional cleaning step was truly necessary.

By potentially eliminating the cleaning step, the customer could not only make their processes more efficient but also achieve significant cost savings without compromising quality.

challengeTechnical Cleanliness Without Additional Cleaning?

The customer faced a crucial question: Can the technical cleanliness of high-voltage components be ensured without the additional cleaning step? And will the high quality standard be maintained? These considerations were focused on optimizing production processes without compromising on quality.

investigationClimate Stress Test to Ensure Technical Cleanliness

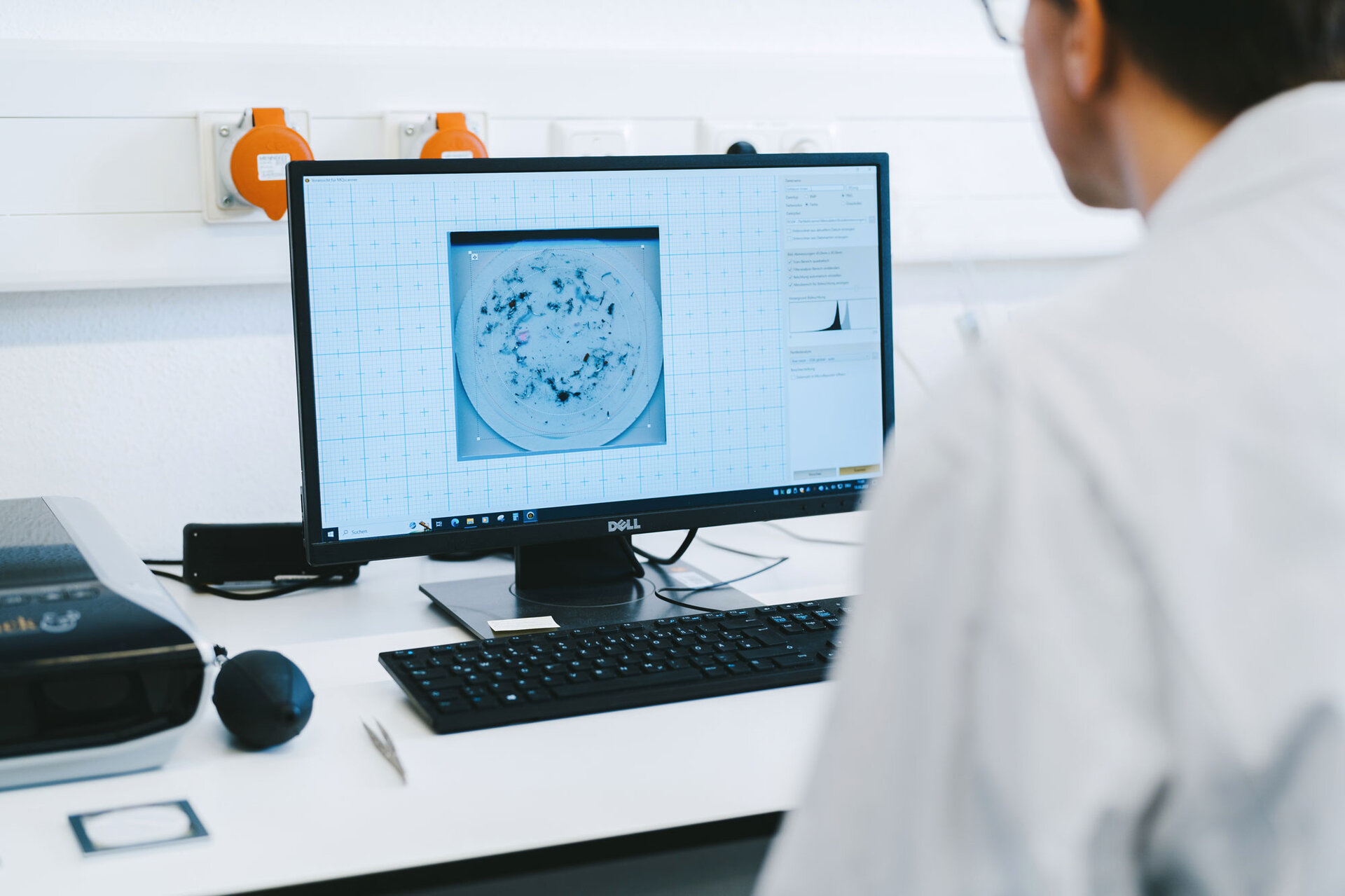

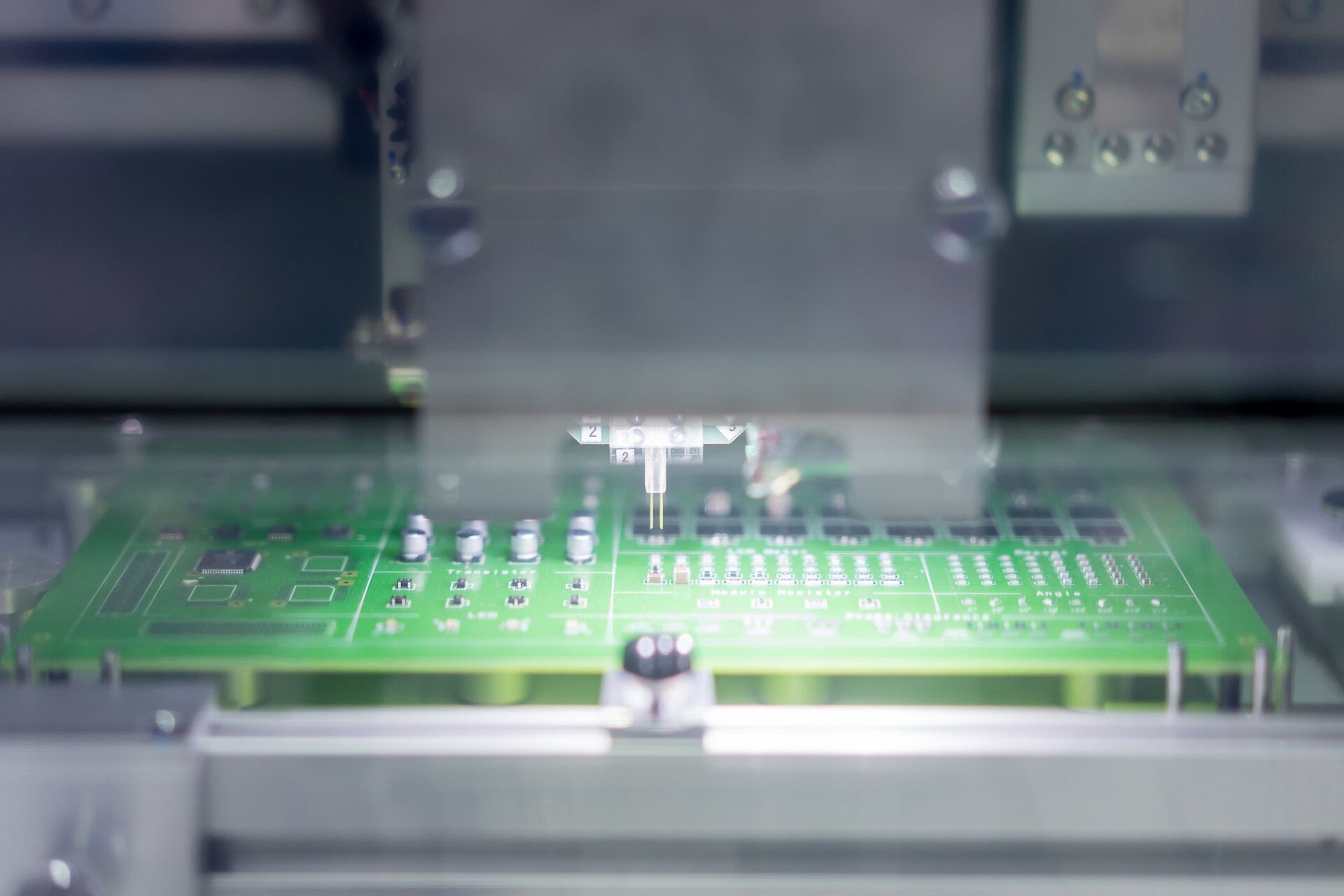

To determine if the protective coating would suffice without prior cleaning, the assembly underwent a comprehensive climate stress test—both with and without particulate contamination.

The results demonstrated that the technical cleanliness and the durability of the assembly under humid climate conditions were maintained even without the additional cleaning step. This opened up the possibility of eliminating the particle removal system.

more analysisWeakness in Protective Coating Discovered

Upon further analysis, a critical weakness was identified. The insulating material exhibited insufficient protection against moisture exposure under high voltage conditions. This weakness could have compromised the functionality of the assembly and led to a higher failure rate in the worst-case scenario.

SolutionOptimizing Insulating Material for Maximum Technical Cleanliness

After the analysis revealed that the insulating material provided insufficient protection under moisture and high voltage conditions, prompt action was required. To address this issue, new process parameters were developed to improve the ventilation and drying of the insulating material. These optimizations led to a higher degree of material crosslinking, preventing degradation under combined stresses.

As a result of these measures, the customer was able to ensure technical cleanliness of high-voltage components, reduce costs, and maintain the high quality and reliability of their end products.

What Challenge Can We Help You With?

whitepaper-collectionTechnical Cleanliness in Electronics Manufacturing

Discover the risks of particle contamination in the electronics industry and explore effective cleaning methods to ensure technical cleanliness. Request information now to meet customer expectations and reduce particle loads.

assistance moduleTechnical Cleanliness

Particulate contamination endangers the reliability of assembled printed circuit boards. Our tailored module helps you prevent risks at an early stage or effectively resolve existing issues. Fully customized to your specific requirements.