How do the flux residues affect the reliability of circuit assemblies?

Discover the issues that will arise from untreated residues if not properly managed.

flux residuesWhat are flux residues?

Flux is a chemical substance used in various soldering processes to improve the flow of molten materials to the bonding surface and its primary task is to remove existing oxides and prevent new oxides from forming during the high-temperature soldering process.

After the process, contaminations like ions, metal salts and organic matter usually remain on the workpiece. The contaminations are identified as flux residues.

Depending on the type of product application or purposes, cleaning of flux residues is needed to avoid situations like electro-migration or corrosion and to ensure reliability.

Flux residues Types of Flux

Rosin-based flux: If rosin-based fluxes are used, the residues primarily comprise rosin and its byproducts. These can be sticky and may require special cleaning to remove.

Water-soluble flux: Fluxes containing organic acids or halides can leave behind acidic residues, which can be corrosive and may cause long-term damage to the soldered components, usually clean with DI water.

No clean flux : Some modern fluxes are designed to leave non-corrosive residues, which are less harmful, low residues and design for no clean.

How do flux residues affect the reliability of circuit assemblies?

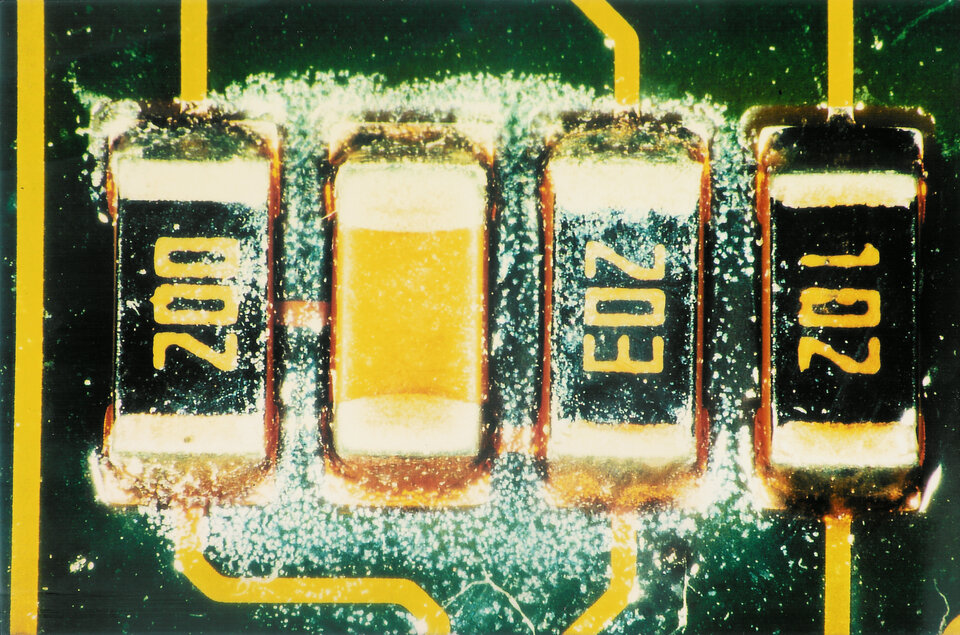

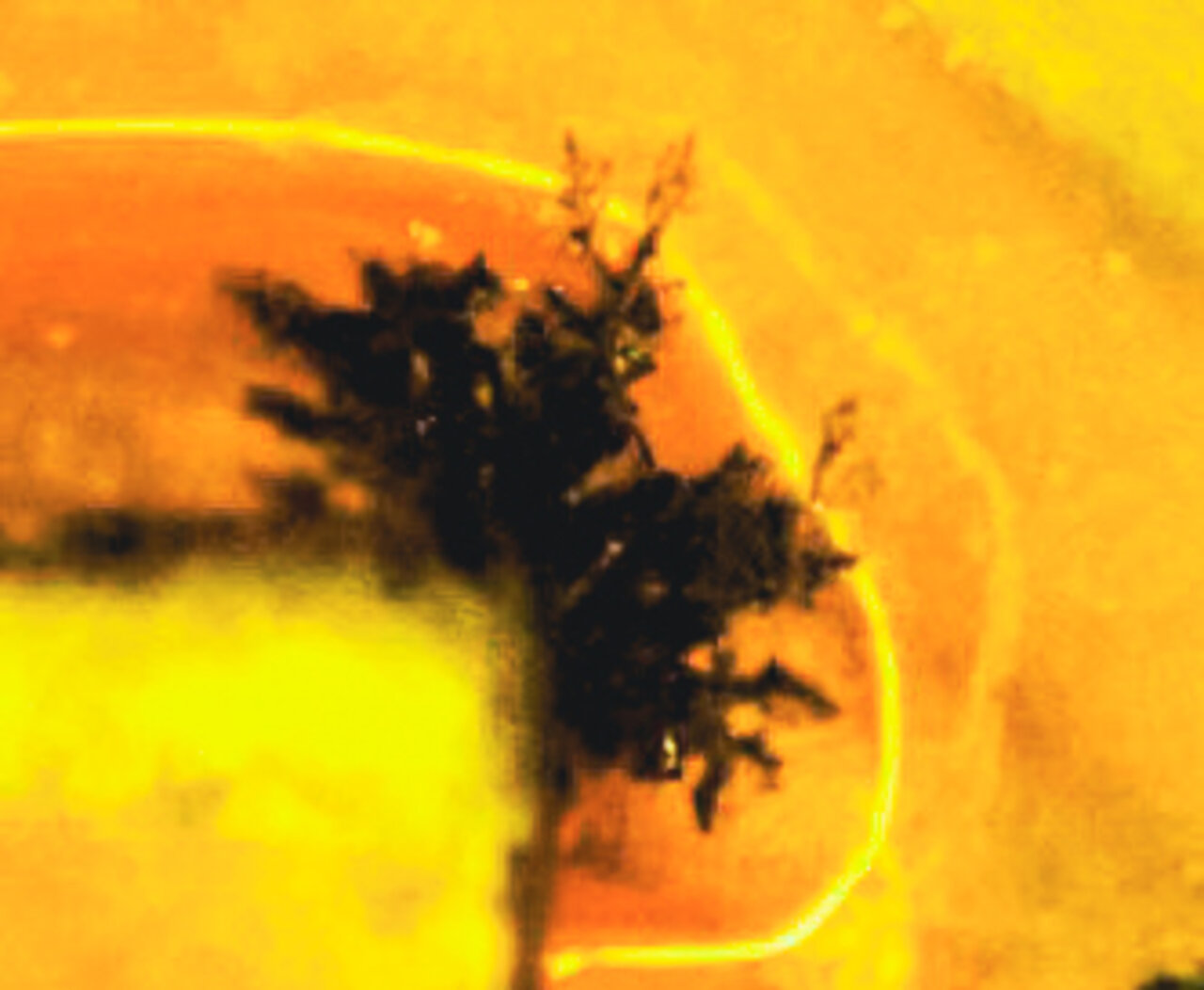

Flux residues are often a mixture of various components (solvent, flux activators, Rosin/resin, Thixotropic agent and etc) that form composite residues. Some flux residues may be invisible or have minimal impact on surface texture, making them difficult to detect.

In fields such as automobiles, aerospace, and communications, where high reliability is required, cleaning of flux is necessary.

Here are some of the common problems associated with flux residues:

- Electrochemical migration due to dendrites growth

- Creepage Current

- Wire bonding failure

- Poor adhesion of coating / molding

- Coating peeling, cracks

- Bit failure in high frequency connection

- Contact corrosion

To effectively clean these residues, it's crucial to choose the right cleaning agents and based on the type of residue present.

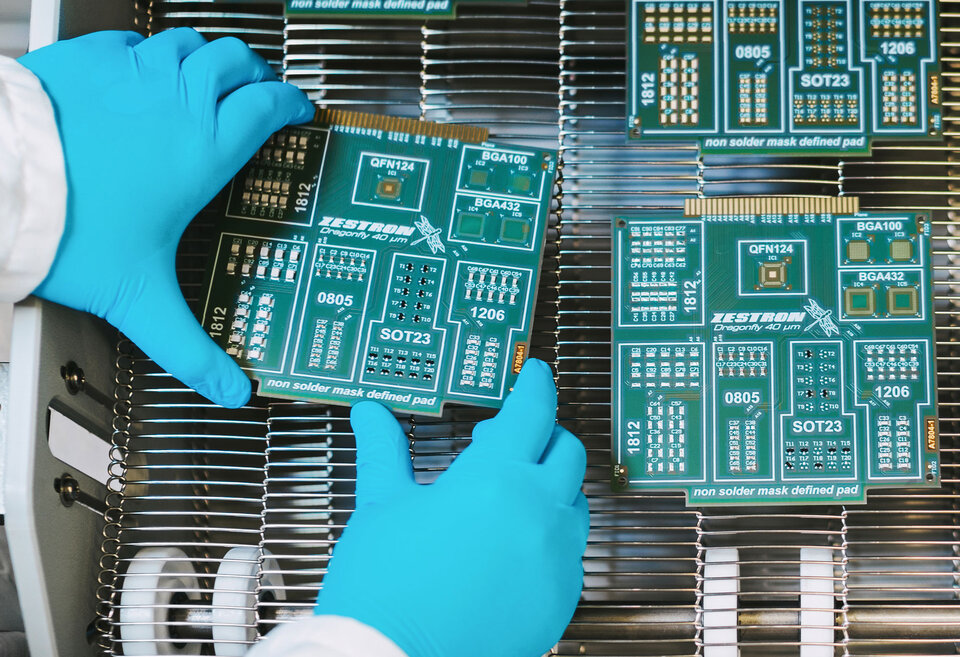

Reliability cleaningCleaning flux residues for higher reliability

Cleaning off flux residues ensures the final product remains reliable, safe, and functional. Proper cleaning procedure ensures that flux residues do not affect the performance or reliability of the electronic devices.

Considerations for creating a proper cleaning procedure:

1) Cleaning Agents

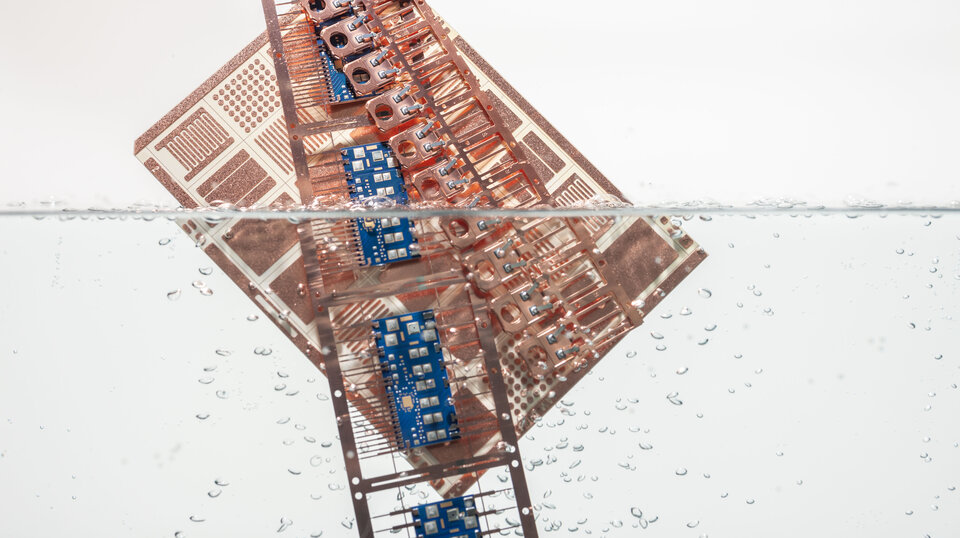

2) Cleaning Process

3) Cleanliness Assessment

It is necessary to complement the cleaning agent, cleaning process & cleanliness assessment to create the right procedure and achieve the best result on different types of workpieces.

Cleaning processZESTRON Support

Achieve optimal cleaning performance with our expert technical support.

Through meticulous cleaning trials conducted at the Zestron Application Technology Centre in Penang, we equip you with precise process recommendations, critical operating parameters, and valuable insights.