ensure optimal performance & reliabilityPackage Cleaning

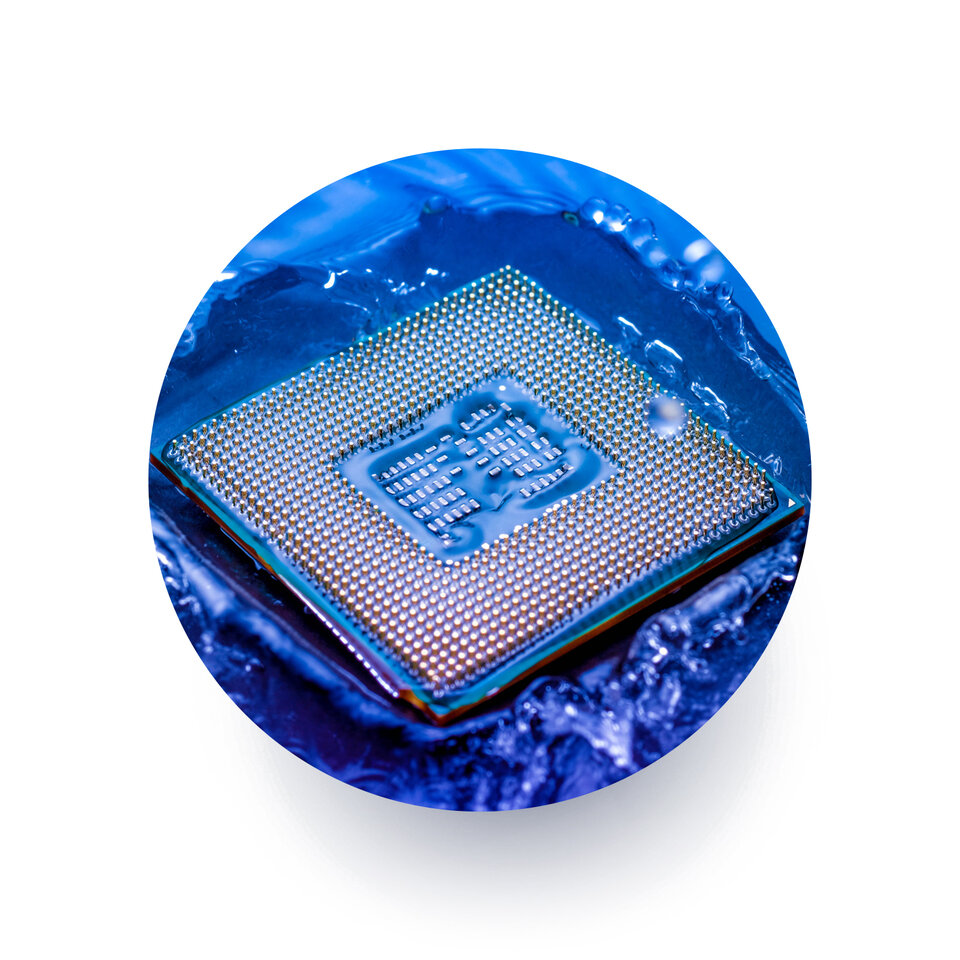

ZESTRON offers water and solvent-based cleaning agents that have been designed explicitly for packages such as flip chips, CMOS, and BGAs.

water & solvent based solutionsAdvanced Packaging

Our products are formulated for removing flux residues after pre-balling, i.e., the solder bump reflow process, from the tight spaces and capillaries between the chip and base materials.

We ensure that CMOS sensors are free of streaks and particles, guaranteeing flawless image resolution. With the complete removal of flux residues and particles, optimal wetting of the underfill materials can be guaranteed.

cleaning prior to underfill

Flip Chip Cleaning

For component types such as FCBGA, FCmBGA, and micro-FCBGA, the electrical contacts (bumps) are soldered onto the component base, utilizing a combination of Flip Chip and BGA structures whereas using a reflow process. For the die attach process during Flip Chip manufacturing, flux pastes (tacky fluxes) are required and applied via a dispenser, spraying, or a chip dip process. Removing all flux residues from the tight spaces between the Flip Chip and the base material is required to achieve complete and void-free wetting of all materials for the underfill process.

- Excellent wetting characteristics for the cleaning agent to properly penetrate the capillary spaces and remove the flux residues

- Excellent rinsability of the cleaning agent to ensure the complete removal of residues under components

- Residue-free drying to ensure a completely cleaned package

ZESTRON's aqueous and solvent-based cleaning media developed for Flip Chip processing guarantees proper underfill wetting, thereby preventing underfill voids.

cleaning for optimal underfill conditions

CMOS Cleaning

Manufacturing camera modules (CMOS), Flip Chip, or BGA-based image sensors are soldered onto the base substrate using a reflow process. For the die attach process, flux pastes are used (tacky fluxes) and applied via dispensers, spray, or chip dip processes. As a result, there are two critical requirements for the cleaning process when manufacturing (CMOS):

- The complete removal of flux residues from capillaries through optimal wetting i.e. penetration as well as rinsability of the cleaning medium

- The complete removal of all particles from the production process

ZESTRON’s water and solvent-based cleaning media for this application feature excellent penetration into tight spaces and instability. They provide:

- Optimal flux removal.

- Enabling void-free underfill and guaranteeing particle and streak-free glass filters of image sensors.

- Ensuring excellent image resolution and preventing pixel defects.

cleaning after the balling process

BGAs & Micro BGAs

The external connections are formed at the base during the balling process of BGAs and micro BGAs. Normally, solder spheres are soldered onto the bottom of the package using a tacky flux. Flux residues need to be entirely removed. If partially cleaned, they can lead to component failure through electrochemical migration and corrosion-induced leakage currents.