long-term reliabilityPrecision Cleaning for Electronic Assemblies

Reliability that powers your electronics.

your true partner

Reliability Matters

ZESTRON provides years of industry experience to ensure your assemblies' performance, reliability, and longevity.

Whether implementing a new cleaning process, optimizing an existing one, or adhering to new regulations - ZESTRON is your partner for long-term reliability in critical applications.

STart the Process

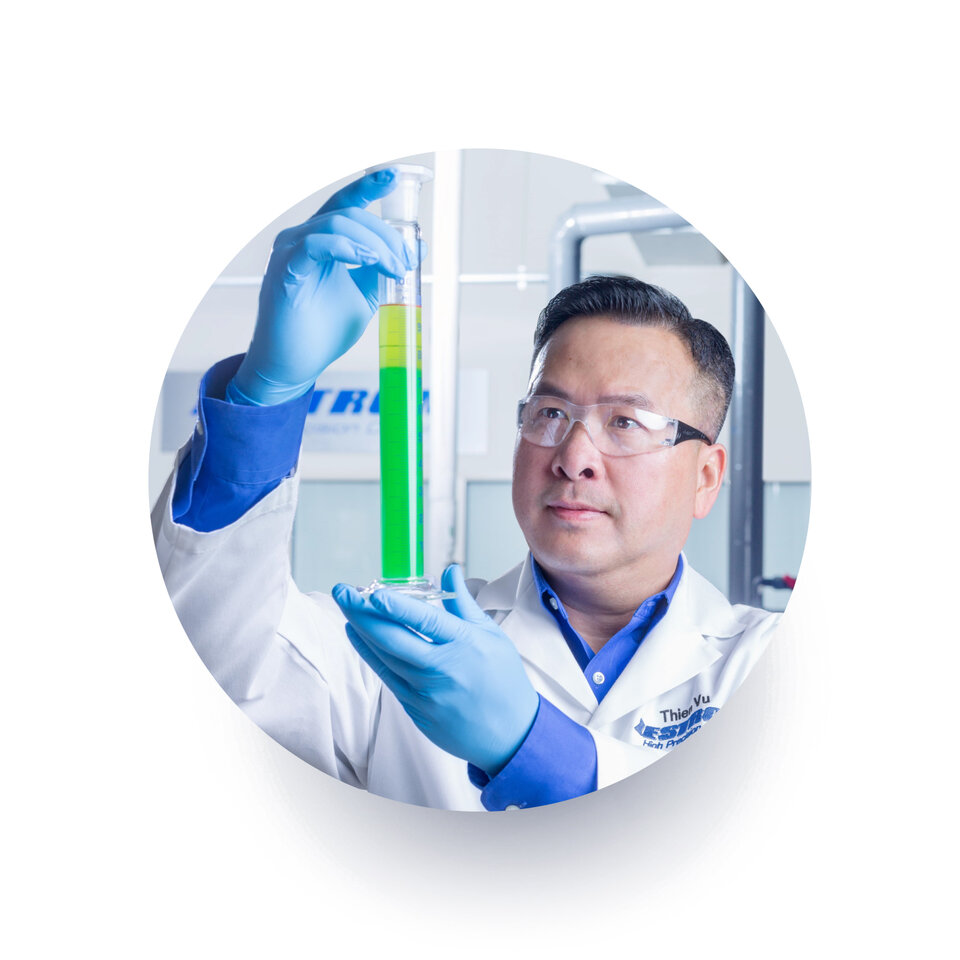

Cleaning Process Setup & Support

Consult with our highly-experienced Application Engineers team to define your process's scope and parameters. Consider our team an extension of your capabilities, supporting you and your operation from beginning to end.

evaluate. educate. optimize.

ZESTRON Technical Center

Wtih a comprehensive selection of more than 15 cleaning machines by leading equipment manufacturers, our Application Engineers assist and guide you with selecting the most suitable machine type and most effective engineered cleaning agent for your process.

cleanliness analysis for assemblies

Analytical Testing

As the leader in precision cleaning, ZESTRON is uniquely positioned to offer you the analytical services and expertise needed to ensure you meet your precision cleaning requirements. Ionic contamination testing, Ion Chromatography, SIR, and FTIR - It’s all done right here in our Manassas, VA technical center.

innovation. always.

Cleaning Agents driving Reliability

ZESTRON employs a global team of R&D scientists and Applications Engineers to develop cleaning solutions that are as advanced as the products and applications our customers create. Our products help keep your process one step ahead of the market with industry leading innovations.

experience is the difference

We've got you covered

- Are you setting up a new SMT electronics cleaning process?

- Have you made process changes to your SMT line, such as

incorporating a new flux material or solder paste?

- Are you considering new cleaning technologies to improve

performance versus legacy chemistry or DI-water? - Are you moving from a No-Clean process to cleaning fluxes?

Technical ARticlePCB Surface Finishes & the Cleaning Process - A Compatibility Study

"As most PCBs designed for use in high reliability applications are cleaned or ‘washed’ in water-based cleaning systems, the effect of the cleaning solution on the surface finish is of great concern."