when reliability is requiredCleaning Process Support

Implementation. Optimization. Qualification.

the zestron promiseYour Process. Our Support.

Consult with our highly-experienced team of Application Engineers to define the scope and parameters of your process. You can consider our team an extension of your capabilities, supporting you and your operation, from beginning to end.

SOLUTION-ORIENTEDSolving your challenges

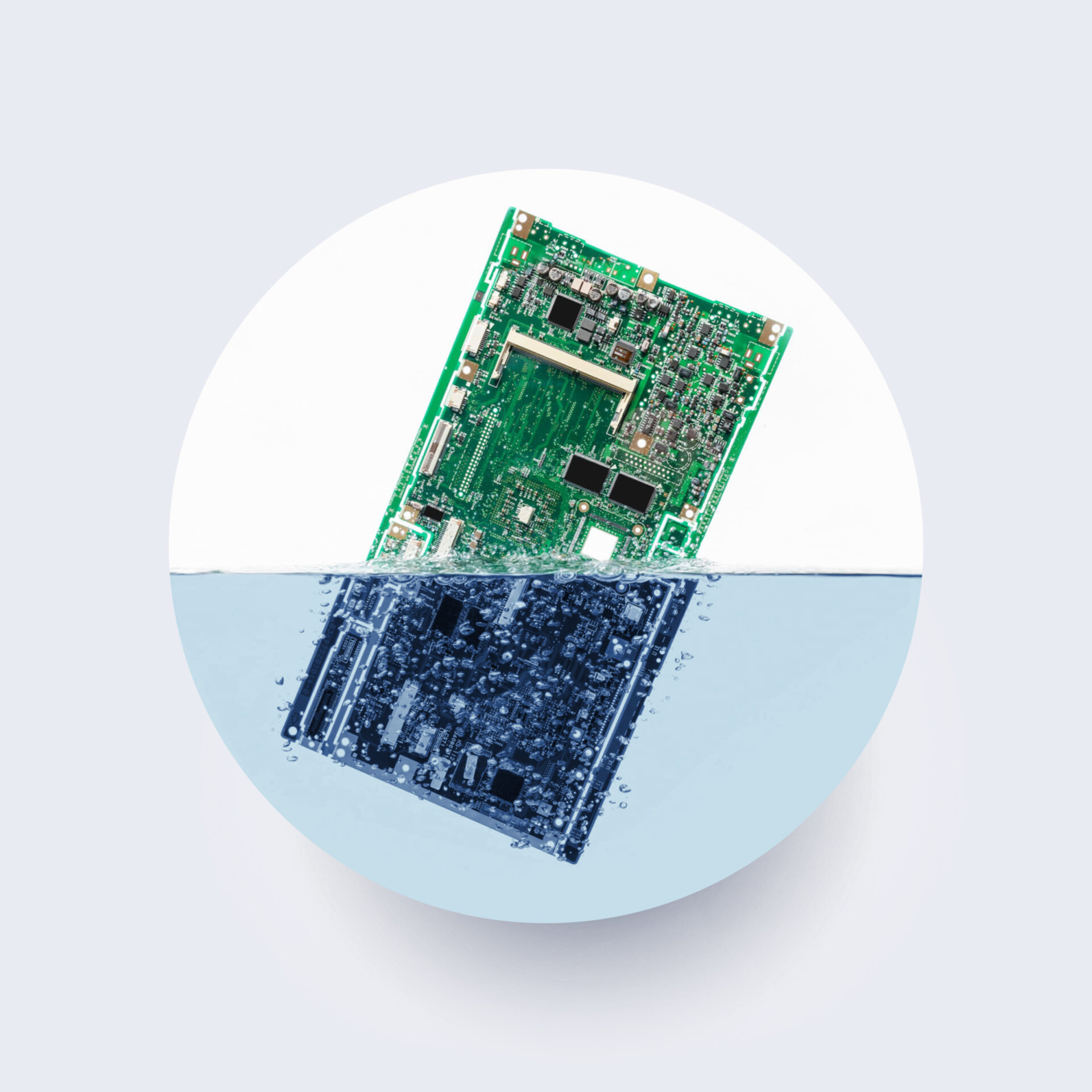

ZESTRON is your partner when the highest reliability for your boards is required – We work alongside our customers with process optimization and risk avoidance, right through to damage analysis.

Our process engineers test your assemblies, semiconductors, or power electronics modules under production conditions utilizing the cleaning equipment of leading manufacturers to identify the best combination of machine, cleaning chemistry, process monitoring, and cleanliness analysis.

Guiding you for successProcess Implementation

As part of our comprehensive start-up implementation program, ZESTRON guides you through the entire development and implementation of your new cleaning process.

A precision cleaning process is selected and qualified by customers based on extensive testing performed in specific machine types and configurations, as well as substrate cleanliness analysis per IPC standards. However, this is just the beginning of defining a quality cleaning process. Effective process implementation at a customer site and documentation of process parameters are critical to the long-term stability and reliability of the cleaning process.

Our Application Engineers provide hands-on support during the equipment integration into your production line. We provide customized training for your personnel and operators, ensuring they are equipped to operate and maintain the cleaning process such that the high level of required cleaning results is achieved reliably and consistently.

Following implementation, our Application Engineer works with your team to monitor your cleaning process through our Bath Analysis program, ensuring the cleaning agent bath life is maximized, and process costs are minimized.

the zestron promise

Key Benefits

- Comprehensive and dedicated application engineering services

- Detailed documentation of operating parameters

- Customized training

- Experience from over 2000 installed processes worldwide

"Ravi has always been a great help and aided us in every step of this trial. He made sure we were in good shape from cleanliness specs to helping us get data to assure our customers that this was the right move. I could always count on his and ZESTRON's help."

Altek Electronics

ensuring efficiency & reliability Process Optimization

Any modification in a manufacturing process, such as introducing a new solder paste, adding a new product, or changing the soldering profile, will require possible cleaning process changes. Any process change requires a detailed review or optimization to guarantee that the necessary level of cleanliness is achieved.

By conducting substrate cleanliness assessments at our Technical Center and detailed process reviews at your location, our Application Engineers will redefine and document all cleaning process operating parameters to ensure your cleaning requirements are met.

Whether it's adjusting process times, setting a new media concentration, or optimizing the temperature window - where necessary, our experts will find the right solutions to maximize the efficiency of your process.

We don't stop there. In addition to the optimization, our engineers also examine the process peripherals, such as the media filtration and the surface purity, completed in our in-house analytical testing facility, ensuring reliability for your process.

the zestron promiseKey Benefits

- Comprehensive cleaning process assessment and optimization conducted by a ZESTRON Application Engineer

- PCB cleanliness assessment according to current IPC standards

- Peripheral device inspection, evaluation and recommendations

- Detailed reporting of surface cleanliness and, thus process reliability for internal and external ISO audits

step insideVisit the ZESTRON Technical Center

Step into our Technical Center from the comfort of your desk with this 360° tour. Look around; with 15+ cleaning machines from leading equipment manufacturers, we are your one-stop shop to find the best option for your process.

the zestron promise50% Off Your Trip

Do you need help finding the right machinery and cleaning processes for your needs? Then it’s time to pack your bags!

At ZESTRON, we’re so confident in our products, world-class technical centers, and ability to assist you in finding the right process – we’d like to prove it to you.