Wafer Bump Defluxing That Works.Wafer Cleaning

The wafer cleaning process involves using our specialized cleaning solutions designed to remove contaminants such as particles, organic residues, and metal ions from the surface of the wafer. Our cleaning solutions are formulated based on the type of contaminant to be removed and the substrate material of the wafer.

Quick. Clean. Safe.

ZESTRON's cleaning ability includes Wafer Bumping Defluxing and PR Stripping:

-

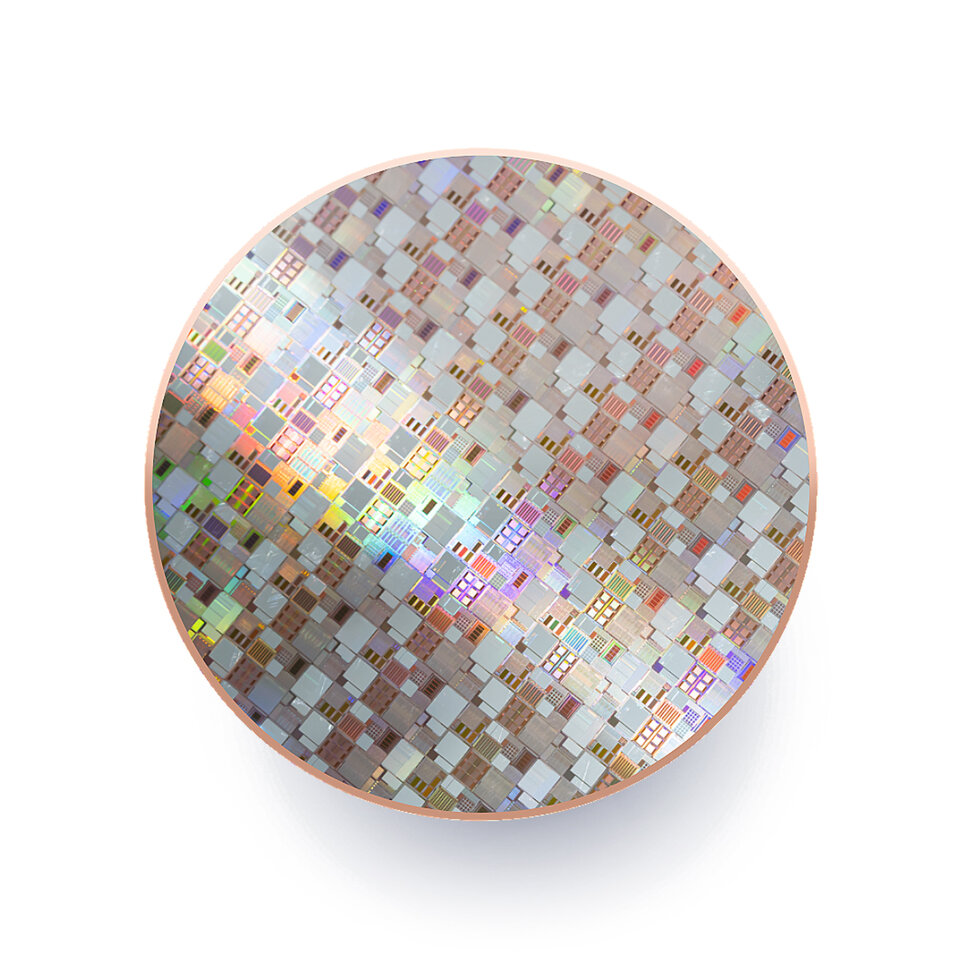

Pre-soldered Si-Wafer with Power Dies

-

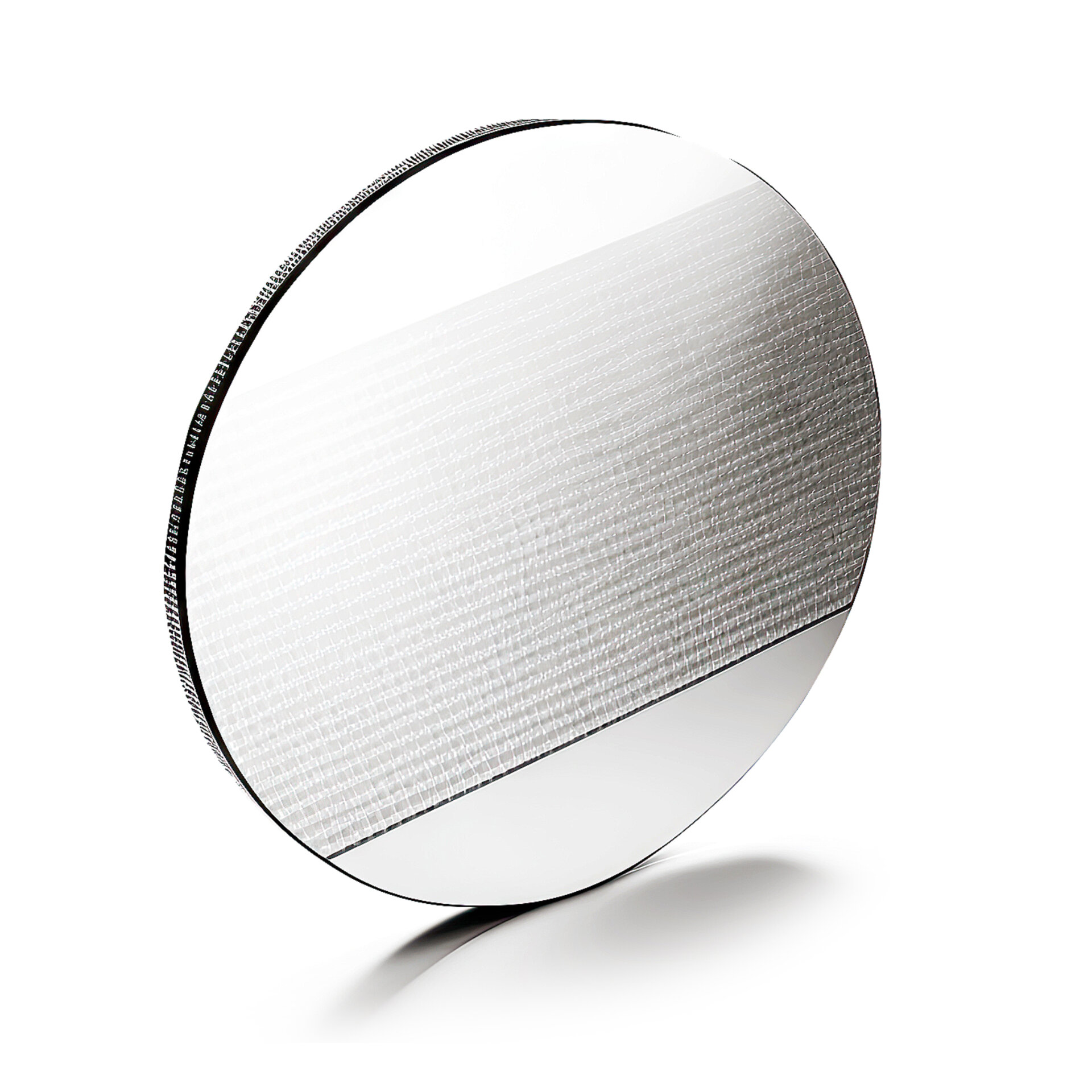

Glass Wafer with Structured Solder Joints

-

Si-Wafer with Solder Bumps

-

Copper Wafer with Photo Resist

-

CoW (Chip on Wafer)

-

Silicon Ingot Cutting and Wafer Dicing

-

Single Wafer and Magazine Cleaning

Water & Solvent Based Soultions

Using innovative technology to push traditional packaging beyond typical limits?

Don’t let flux contamination get in the way of performance and reliability.

- Rapid Results

Achieve a complete clean in under a minute, meeting or exceeding standard productivity expectations.

- Consistently Clean

Remove particulates and impurities, reducing crystal defects, interconnect failures, oxidation, corrosion, migrating satellites and delamination all without the risk of material compatibility impact of sensitive metals.

- Cost Saving

Increased savings in terms of reduced process time and increased throughput

- Safe & Sound

Benefit from a environmentally friendly, aqueous solution with zero flash point and no specialized waste water disposal requirements.

THE RESULTS ARE CLEAR.

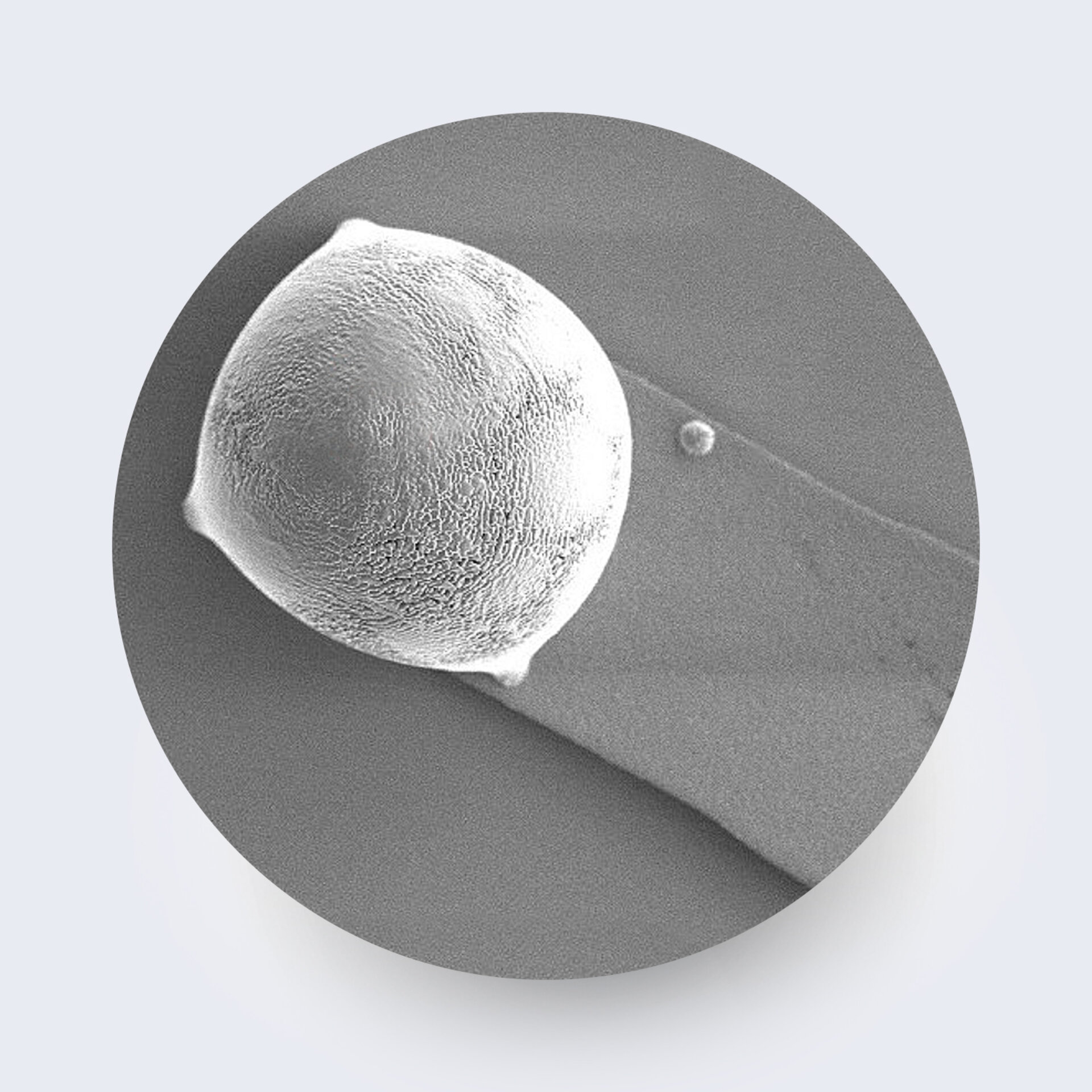

OUR SOLUTIONS REDUCE CARBON CONCENTRATIONS FROM 55% TO 0.1%

Pre-Clean | EDX

Clean | EDX

EDX - Energy-dispersive X-Ray Spectracopy

Pre-Clean | SEM

Clean | SEM

SEM - Scanning Electron Micrscope