PCB Defluxing & Cleaning

Cleaning your PCBs - The Why and How

There are many reasons why a board could fail in the field. When you are manufacturing electronic circuits that are used in high reliability applications, field failures resulting from dendritic growth, electrochemical migration, leakage current, and conformal coating, among others, are unacceptable risks.

The Challenge of Cleaning Complexity

As technological applications become increasingly complex, so do the printed circuit boards that power them. Today, PCBs can do more while utilizing less space through the implementation of the following:

-

Lower component standoff heights

-

Increased board density

-

Stacked and complex component types

-

Increased use of sensitive materials

Get educatedElectrochemical Migration - Origin and Prevention of Field Failures

Electrochemical migration is an important topic for the reliability and durability of electronic assemblies, and is frequently discussed as the cause of malfunctions in the field.

Failure is Not an Option

When cleaning PCB assemblies, the primary goal is to remove contaminants from populated boards and hybrid circuits resulting from fluxes and improper handling. Engineered PCB cleaning solutions are essential to ensure flux residues are entirely removed from the assemblies used in high-reliability applications and industries such as automotive, medical, aerospace, and military.

The risk of failure can be mitigated by removing residue related to production and handling. Components of solder paste (resins, rosins, and fluxes) are integral to the PCB manufacturing process. Still, if residues from these elements are not removed after the assembly process, they can lead to common and predictable problems.

Top Reasons your PCBs Could be Failing:

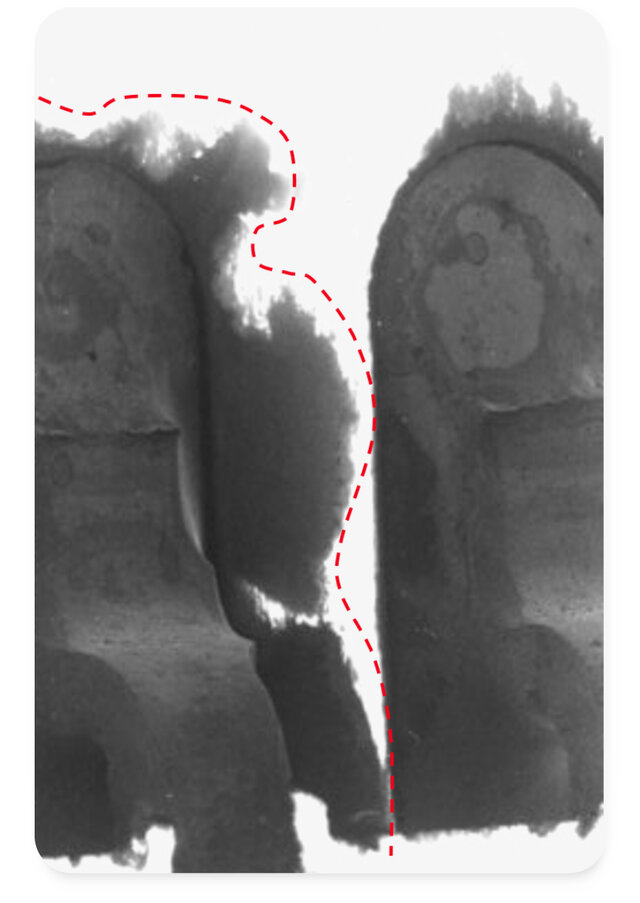

Per IPC-TR-476A, ECM is defined as - “The growth of conductive metal filaments or dendrites on or through a printed board under the influence of a DC voltage bias”.

Two common ECM mechanisms are:

-

Conductive anodic filaments (CAF): migration within a printed circuit board (PCB).

-

Dendritic growth: ECM along a surface that produces a dendrite (tree-line) morphology.

For electrical assembly, current leakage in a printed circuit board (PCB) can result in intermittent or permanent failure. Current leakage can occur due to insulation resistance reduction (due to presence of contamination) between adjacent solder-pads on a PCB.

This hygroscopically induced moisture absorption phenomenon can for example intensify due to dissociated hydronium ions (i.e. from activators), to further result in malfunction and complete assembly failures.

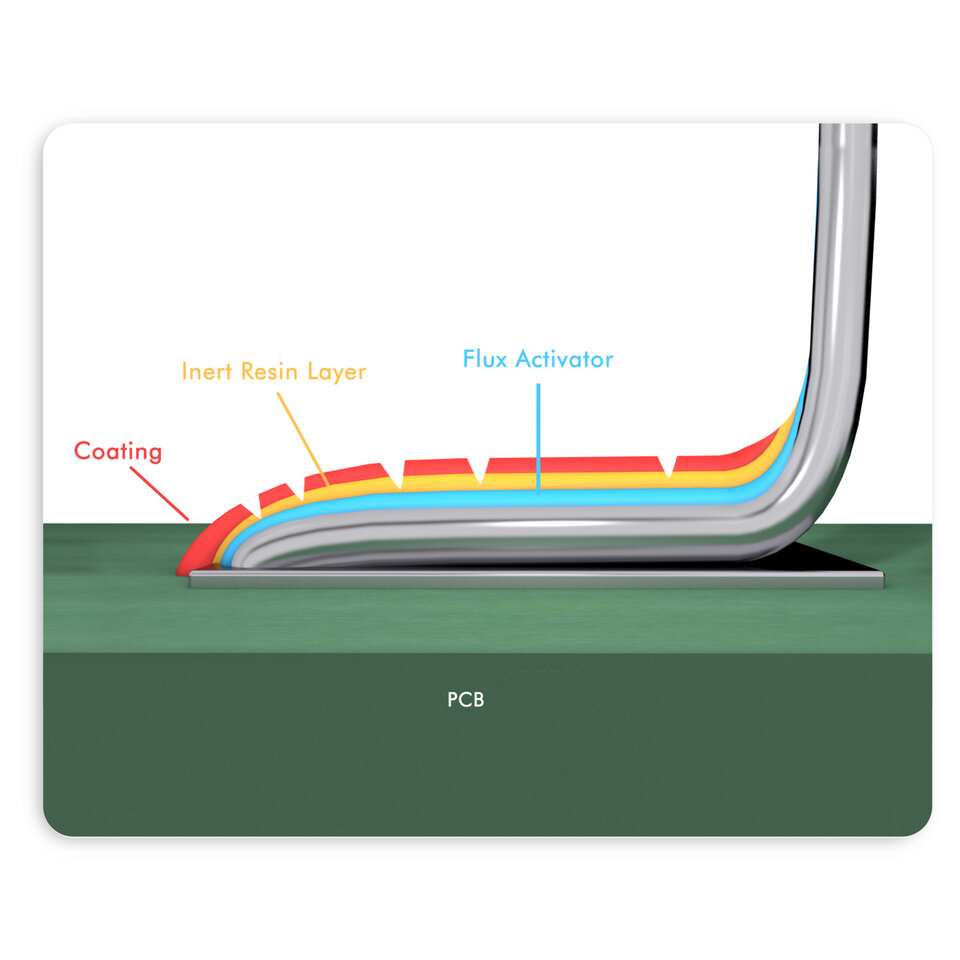

Conformal coatings are layers of material that are applied on and adhere to the PCB and its components to protect from environmental hazards. There are a wide variety of materials used as conformal coatings ranging from thick layers of silicone to nano-coatings like Parylene.

The coating, when applied, will conform to the shape of everything on the surface, including any contaminants or residues leftover from the production process. Trapped contaminants can cause conformal coatings to warp, crack, or peel which re-exposes the PCB to the environmental hazards the coating layer was meant to protect against.

PCB Defluxing Industry Standard Equipment for Cleaning your PCBs

Cleaning the circuit assemblies is a crucial part of any reliability engineering process — proactively mitigating risk by removing the contaminants that lead to field failures. There are industry standards established for cleaning PCBs and multiple options for cleaning depending on your production needs:

Spray-in-air inline cleaning machines are ideal when cleaning electronic assemblies with densely populated boards having low standoff components and when requiring high production throughputs.

The PCBs are placed on an automatic conveyor belt and run through individual process steps, where cleaning, rinsing and drying are performed in separate sections of the inline machine.

The spray-in-air batch system operates using technology very similar to the technology used in a dishwasher. All process steps are executed within the same process chamber. The cleaning medium is sprayed onto the electronic assemblies through nozzle fittings on rotating spray arms.

The cleaning effect is achieved primarily by the volume of cleaning medium passed over the substrates rather than the spray jet pressure like in inline processes.

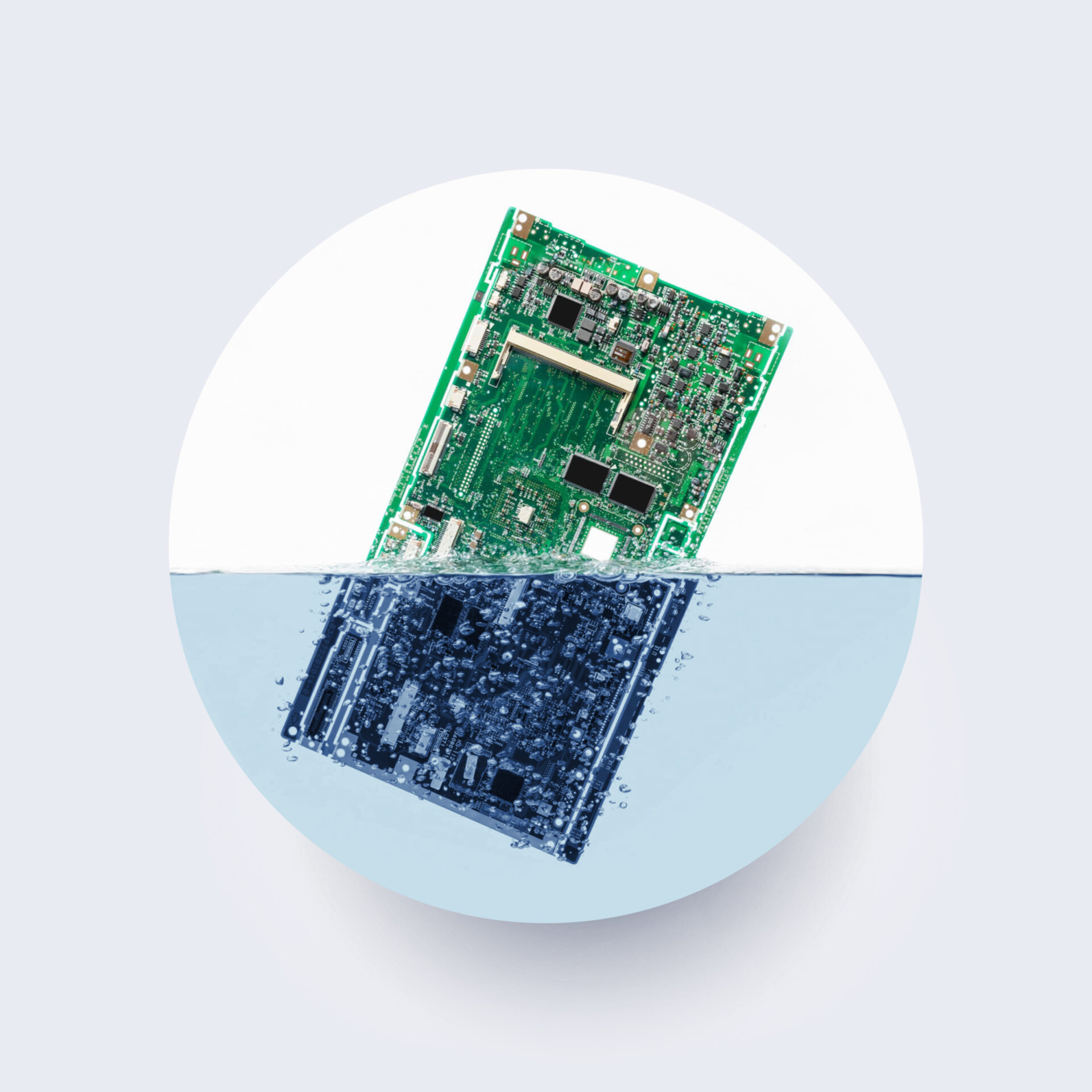

Ultrasonic systems submerse the PCB in a cleaning medium that is then agitated with soundwaves exceeding 20 kHz. Ultrasonic cleaning can be useful in cleaning under components and complex geometries since the sound waves are capable of reaching the populated circuit board from every angle.

Many industry cleaning machines have an automatic frequency adjustment for the modulation of the ultrasound (sweep) working frequency, which prevents “hot spots” and allows material-friendly cleaning.

Sometimes individual PCBs need to be cleaned with unique geometries and materials. In this case, nothing beats good, ol’ fashioned elbow grease. Manual cleaning requires no investment in equipment and is popular in applications where the throughput is low like building prototypes or performing electronic component rework/repair. If a facility is producing medium/high throughput, running several shifts and requires reliable and repeatable cleaning results, an automated cleaning process is recommended.

SOLUTION-ORIENTEDWe've got you covered!

Do you need help determining the best equipment for your process? Our Technical Center in Manassas, VA, has a large selection of cleaning equipment from multiple manufacturers, varying in both size and price, and available for you to test. Our equipment includes Inlines, Batch, Ultrasonic, Vapor Degreasers and much more.