safe & efficientSMT Electronics Cleaning

Environmentally friendly cleaning solutions for Surface Mount Technology (SMT) and Through Hole (THT) Electronics

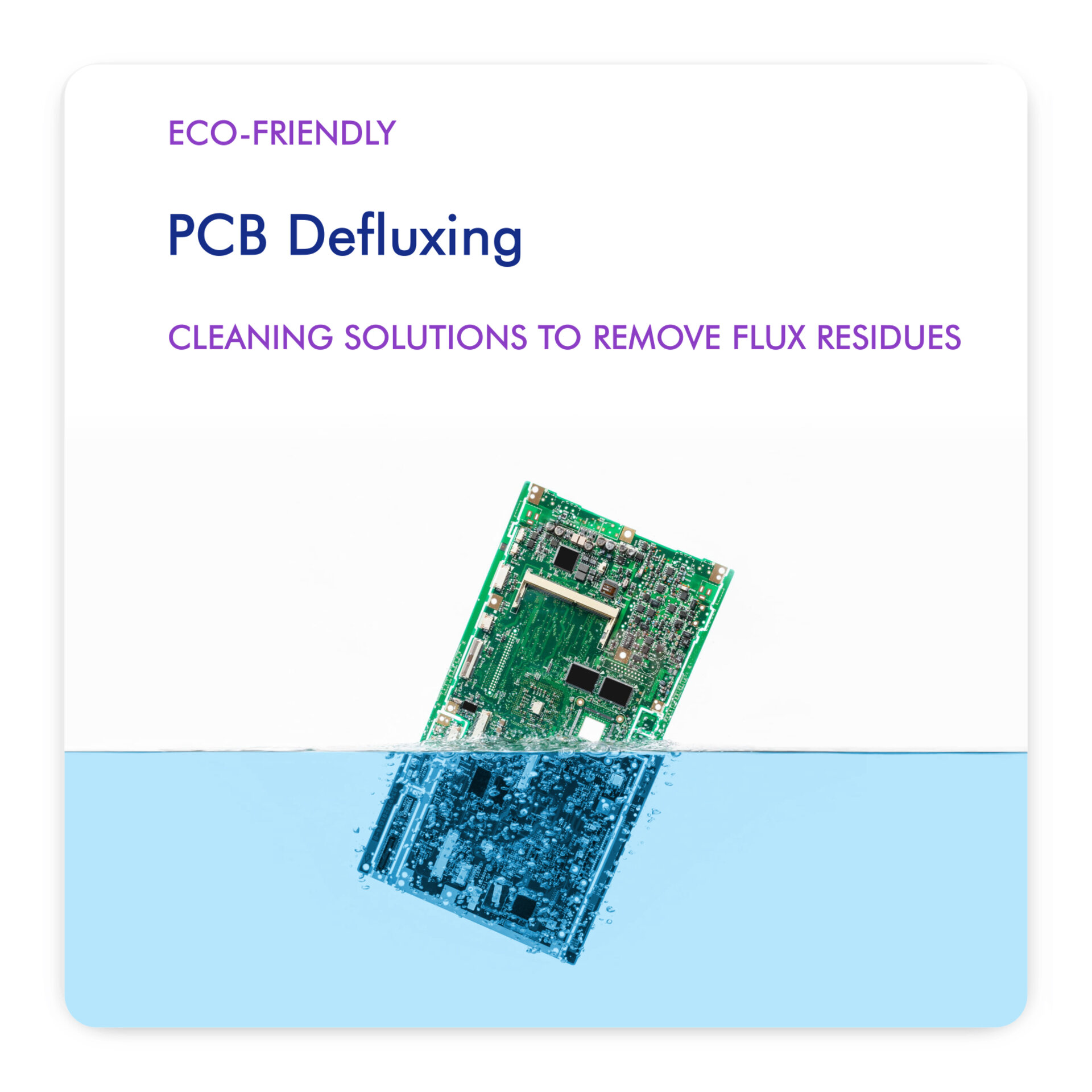

Failure is not an option! When cleaning printed circuit board (PCB) assemblies, the primary goal is to remove contaminants from populated PCBs and hybrid assemblies that can contribute to performance failure in the field. Engineered PCB cleaning solutions are essential to ensure the cleanliness and complete removal of contaminates like flux residues from assemblies used in high-reliability applications and industries such as automotive, medical, aerospace, telecommunications, and military.

When manufacturing electronic assemblies, solder pastes, SMT adhesives, or thick film pastes are printed or applied using stencils, pump print stencils, or screens. Paste residues and remaining SMT adhesives on stencil surfaces and apertures can lead to misprints resulting in bridging and solder balling issues. For optimum print results, cleaning the stencils and screens either manually or using an automated stencil cleaning machine is necessary.

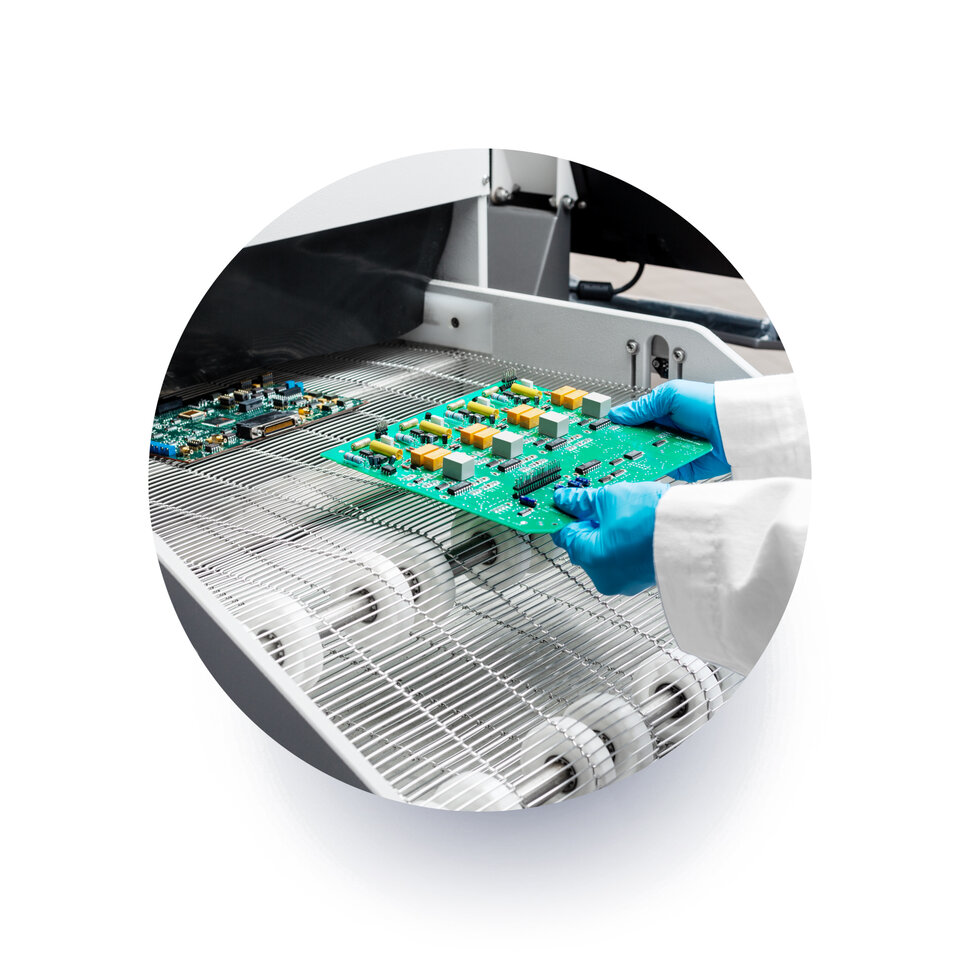

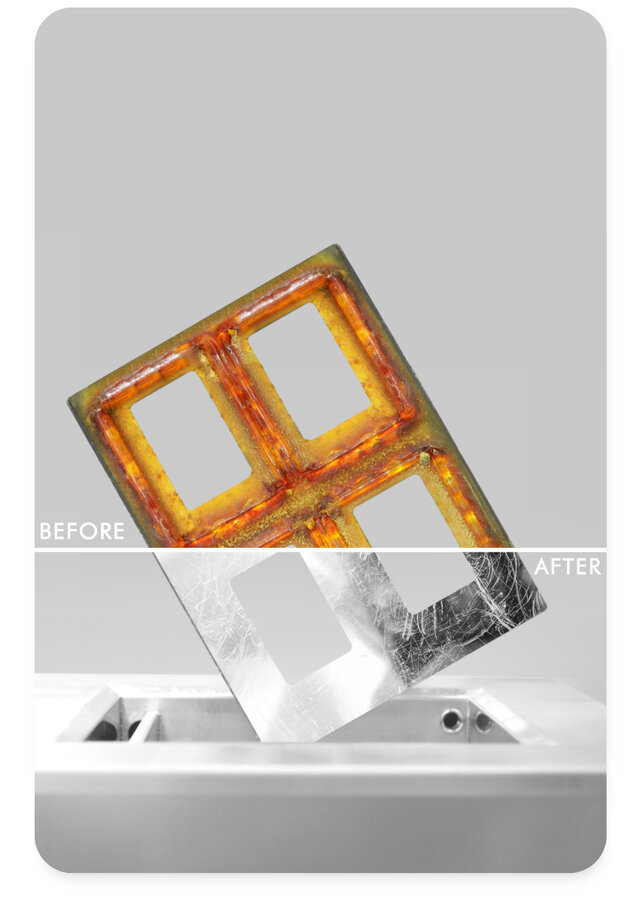

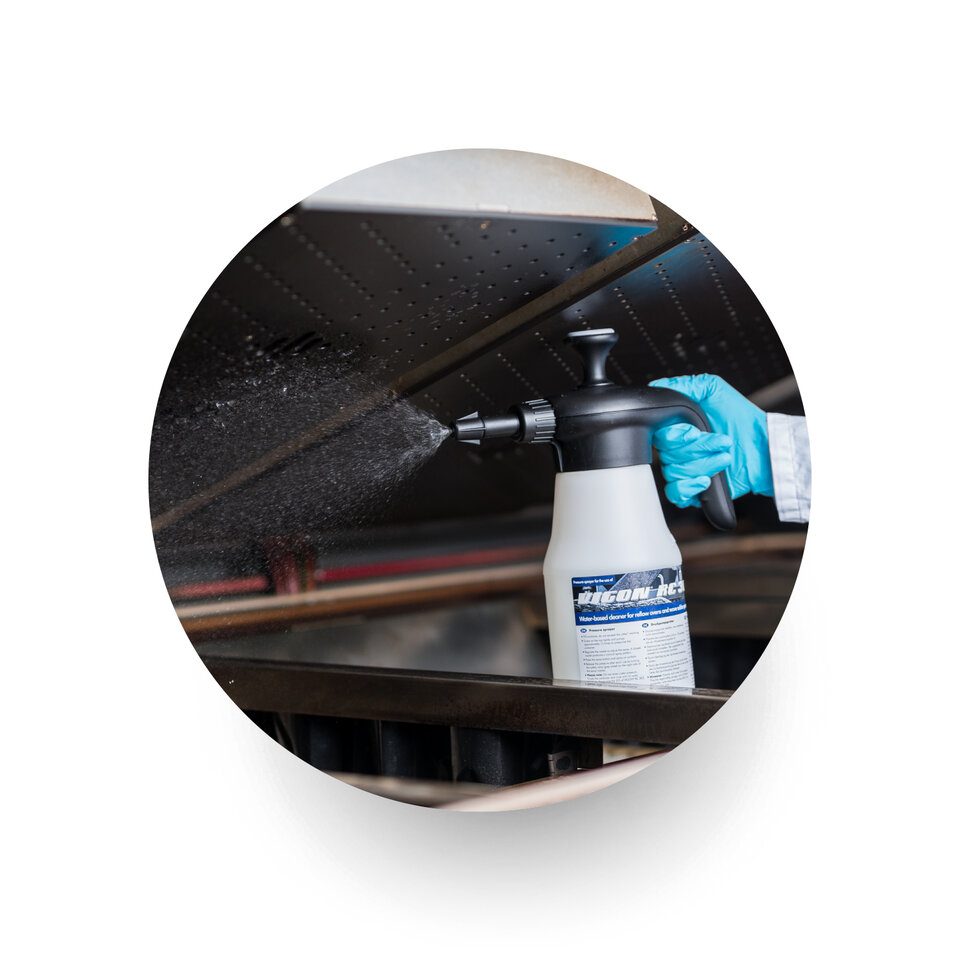

As part of a maintenance cleaning program, the most prevalent types of contamination, such as baked-on fluxes, recondensed gas emissions from the soldering process, and coating residue from pallets and fixtures, must be removed to ensure a reliable and failure-free production process.

Other parts that require maintenance cleaning include dispensing needles, solder pallets, conveyor fingers, condensation traps, reflow ovens, and wave solder machines.