Conformal Coating Removal

Mastering Conformal Coating: Safe & Efficient Techniques from Beginning to End

Welcome to our comprehensive guide on safe and efficient conformal coating techniques. Whether you're a seasoned professional or just starting in the field, understanding the intricacies of conformal coating, from the why, to the proper application to rework and maintenance is essential for efficient and effective operations. In this guide, we'll explore various methods, tools, and tips to help you navigate the process with confidence.

Jump to a section:1. Benefits of Conformal Coatings

2. Reliability of Your Coating

3. Conventional Methods of Conformal Coating Removal

Understanding Conformal Coating

Conformal coatings are thin, nonconductive layers that shield electronic components from environmental damage, serving as a protective barrier against moisture, dust, and corrosion. Used in multiple industries such as automotive, military, avionics, and industrial control electronics areas, in which high product reliability and a long service life are required. Advances in materials and processes continue to expand their use globally. There are multiple types of conformal coatings commonly used in electronics manufacturing:

What are the Types of Conformal Coating?

The types of conformal coatings commonly used in electronics manufacturing include:

-

Parylene: Parylene coatings are deposited as a thin film through a vapor deposition process. They offer excellent barrier properties, moisture protection, and chemical resistance. Parylene coatings are highly conformal and can penetrate into intricate geometries.

-

Acrylic: Known for its versatility, acrylic coatings provide good moisture resistance and are easy to apply and remove. They offer moderate protection against chemicals and abrasion.

-

Urethane: Urethane coatings provide robust protection against abrasion, chemicals, and humidity. They offer good resistance to temperature extremes and UV radiation, making them suitable for outdoor applications.

-

Epoxy: Epoxy coatings provide superior adhesion and chemical resistance. They offer excellent protection against moisture and are often used in high-performance applications.

-

Silicone: Silicone coatings offer excellent protection against moisture, high temperatures, and environmental contaminants. They are flexible and durable, making them suitable for harsh operating conditions.

Each type of conformal coating has its own set of properties and advantages, allowing manufacturers to choose the most suitable option based on the specific requirements of their application.

Get educated

Improving the Quality of Protective Coatings

Protective coatings ensure high reliability in electronics, with thermal shock tests verifying their durability. This study examines how production parameters impact coating faults during these tests, highlighting that cleaning residues improves performance. It also ranks key factors influencing thermal shock reliability.

Shield Components & Assemblies

Applied in thin layers, typically in the microns to mil range, conformal coatings are much lighter than alternative protective solutions like mechanical seals and enclosures. These coatings shield components and assemblies from moisture, fluids, solvents, and chemicals, safeguarding against damage. Offering high dielectric strengths and low dielectric constants conformal coatings provide excellent insulation to precent electrical failures in increasingly compact electronic designs.

Safeguarding Against Damage

Fast temperature changes paired with contamination on your PCB and improper coating adhesion can cause solder breakages, blisters and cracks/delamination in the coating, negatively impacting product lifespan and performance. According to a ZESTRON study on “Improving the Quality of Protective Coatings,” cleaning your PCB prior to coating is the most important factor in reducing failure rates, specifically delamination and crack formation. When it comes to blisters, another important factor is selecting a suitable coating material and applying the coating appropriately.

Conformal coating shields electronic components from environmental damage, serving as a protective barrier against moisture, dust, and chemicals. Proper removal is vital to maintain assembly integrity, enabling thorough inspection and repair. Inadequate removal risks interference with electrical connections and component functionality, potentially causing performance issues or failure.

However, the removal process poses challenges, such as selecting suitable methods, preventing damage to delicate components, and achieving residue-free removal. Overcoming these hurdles is crucial for preserving device functionality and reliability.

Achieve Optimal Results

- Mechanical Abrasion Techniques

- Chemical Stripping Agents | ZESTRON’s ATRON® DC

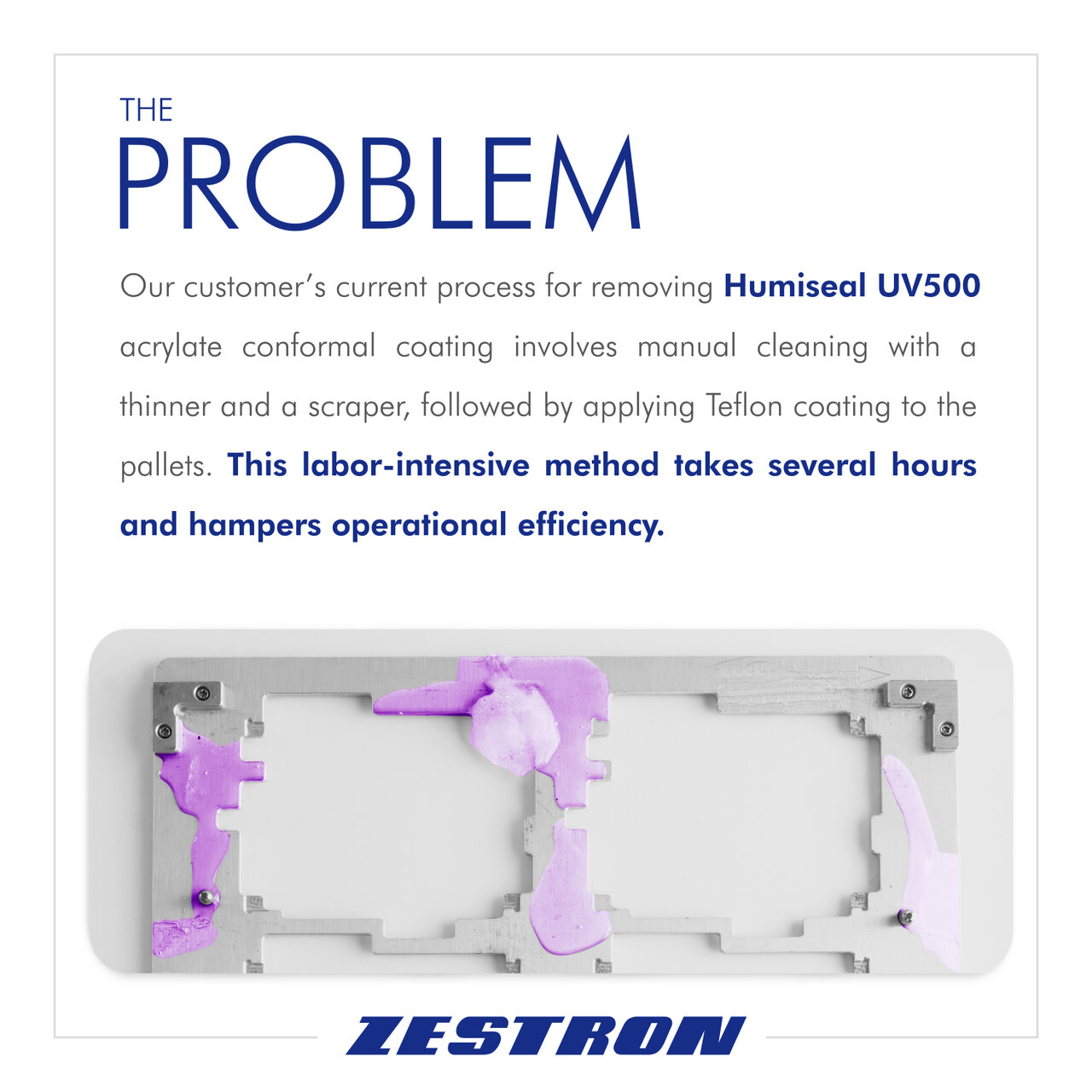

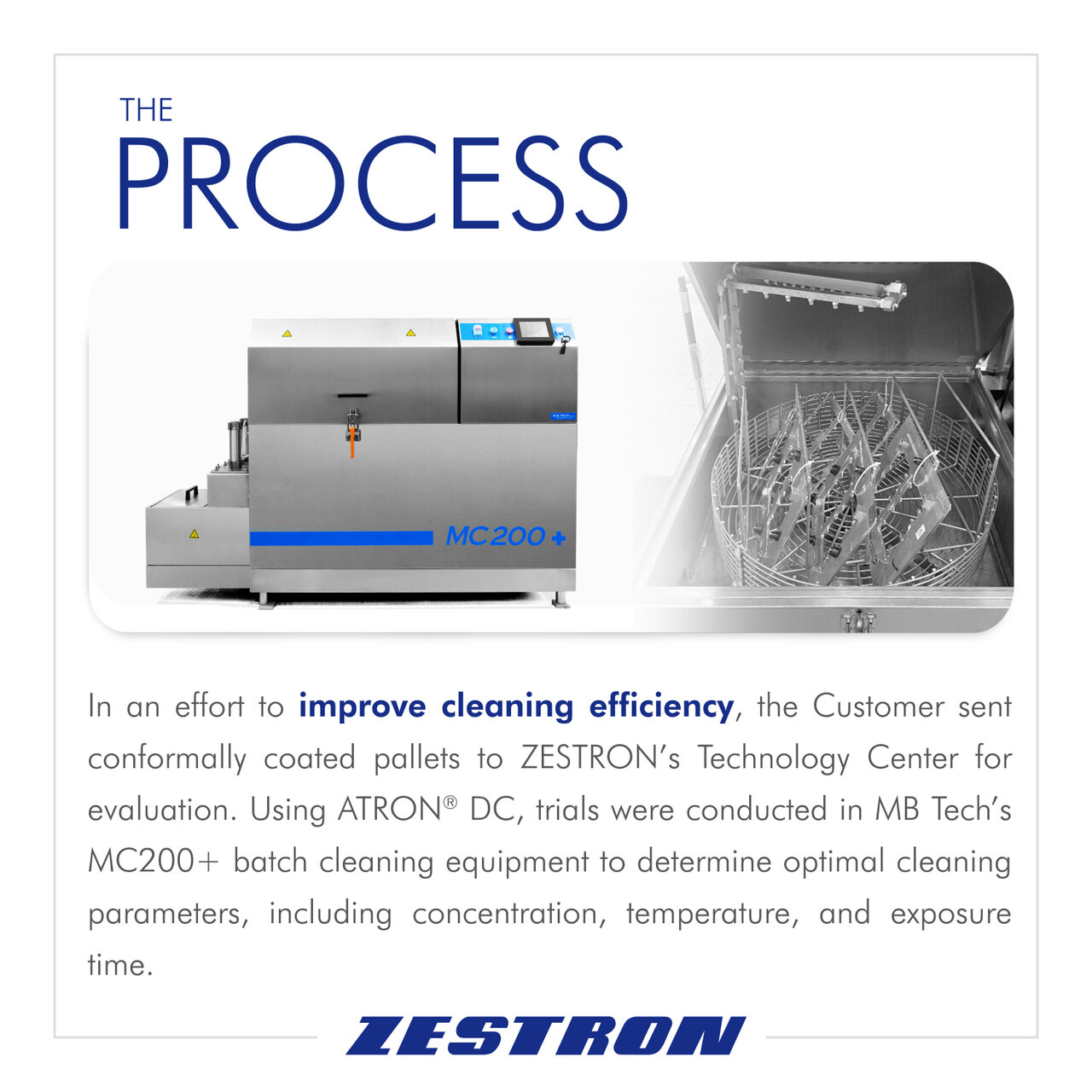

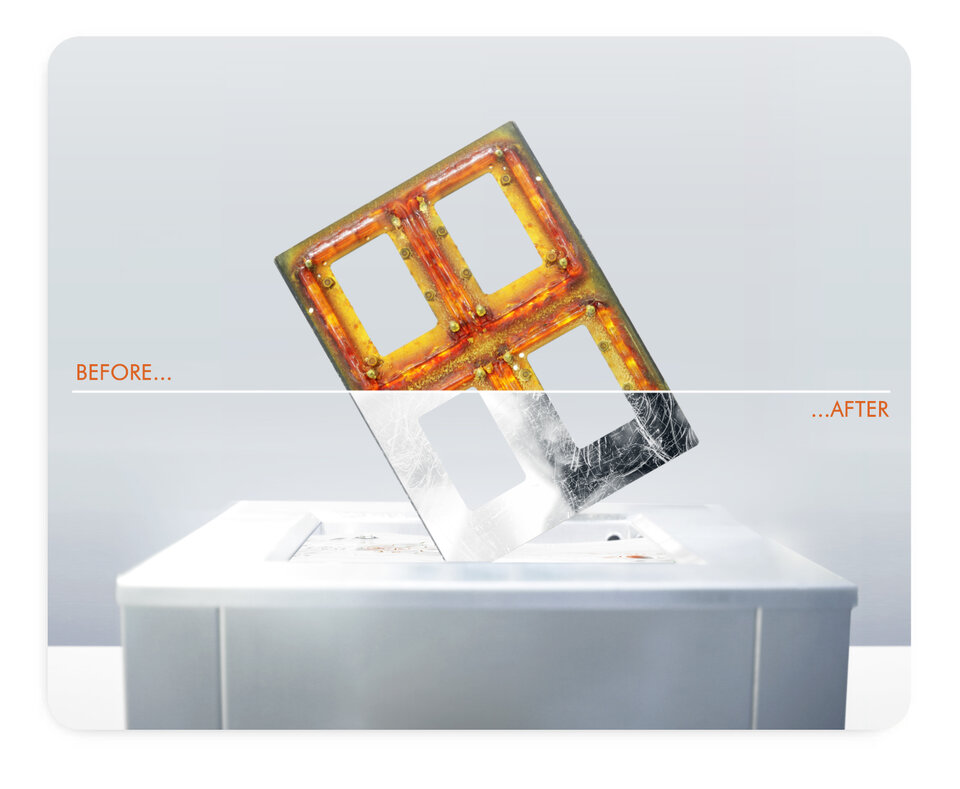

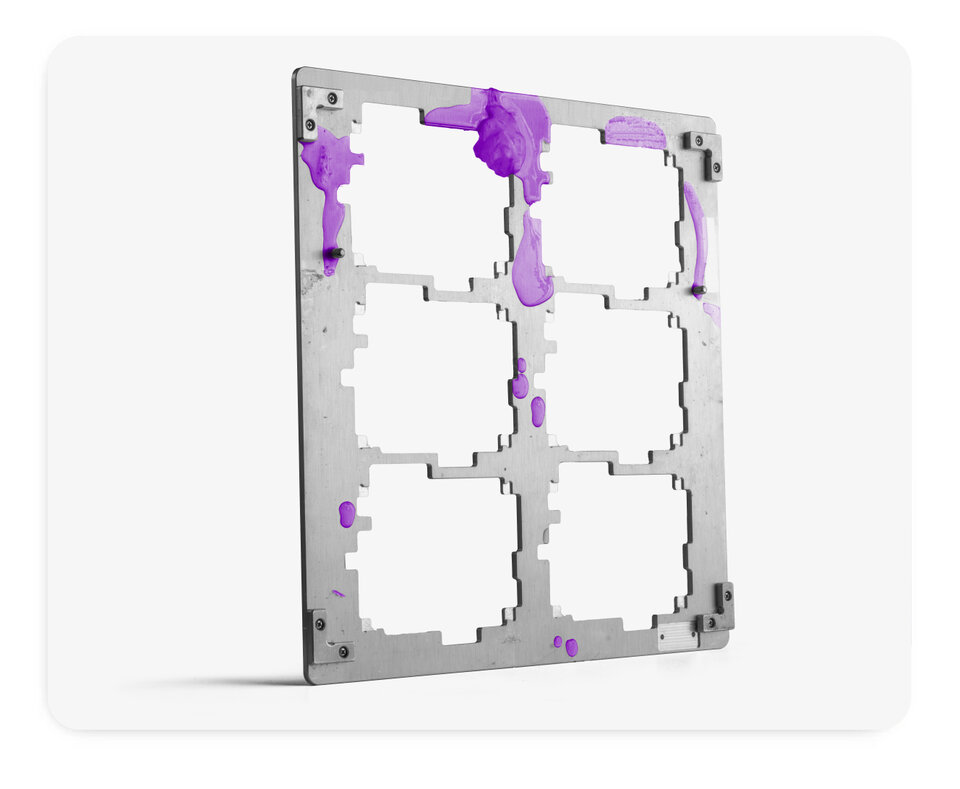

Mechanical abrasion techniques involve physically scraping or abrading the conformal coating using tools such as brushes or abrasives. These methods are effective for removing thick or stubborn coatings but require careful control to avoid damaging underlying components. Chemical stripping agents such as ATRON® DC utilize chemical solutions to dissolve the conformal coating, making it easier to remove. They offer versatility in tackling various coating types. But some harsh solvents necessitate caution due to their potential for environmental and health hazards.

ATRON® DC is the world’s first water-based cleaning agent specifically developed for decoating applications. It reliably removes coatings such as acrylics, urethanes, and epoxies from pallets and fixtures. Compatible with various equipment types, including spray-in-air, dip tanks and ultrasonic systems, it offers unmatched flexibility and efficiency.

Understanding Conformal Coating

Mastering conformal coating removal requires a comprehensive understanding of techniques, tools, and best practices.

Invaluable Insights

- Success Stories from Industry Professionals

- Lessons Learned and Practical Insights

Case studies and real-world applications provide invaluable insights into the practical implementation of conformal coating removal techniques. Success stories shared by industry professionals highlight effective strategies, innovative solutions, and notable achievements in overcoming challenges. These firsthand accounts offer tangible examples of how different removal methods were applied, the outcomes achieved, and the lessons learned along the way.

Through these narratives, practitioners can gain practical insights, discover best practices, and learn from others' experiences to optimize their own conformal coating removal processes.

Conclusion

Confidently Navigate Conformal Coating Removal

Mastering conformal coating removal requires a comprehensive understanding of techniques, tools, and best practices outlined in this guide. Selecting the right tools, implementing safety precautions, and adhering to environmental considerations are crucial for efficient and effective removal processes. Additionally, tips for proper surface preparation, maintaining optimal conditions, and post-removal inspection ensure thorough and high-quality outcomes. Case studies and real-world applications provide valuable insights and practical lessons from industry professionals, aiding in the optimization of conformal coating removal processes. By integrating these strategies and insights, practitioners can confidently navigate conformal coating removal, ensuring the integrity and reliability of electronic assemblies in various applications.

With the knowledge and strategies outlined in this guide, you're equipped to tackle conformal coating removal challenges with precision and confidence. Remember to stay informed about the latest advancements in coating removal techniques and continuously refine your practices for optimal results. Happy coating removal!