the cleaning chroniclesResolving the Ghosting Phenomenon

PCBs are essential components that ensure the smooth functionality and reliability of electronic devices. A critical step in PCB manufacturing is the application of a protective layer known as solder mask, which serves to insulate, prevent short circuits, and safeguard the copper traces on the PCB. However, when the solder mask is improperly cured, it can have significant consequences, potentially compromising device performance and lifespan.

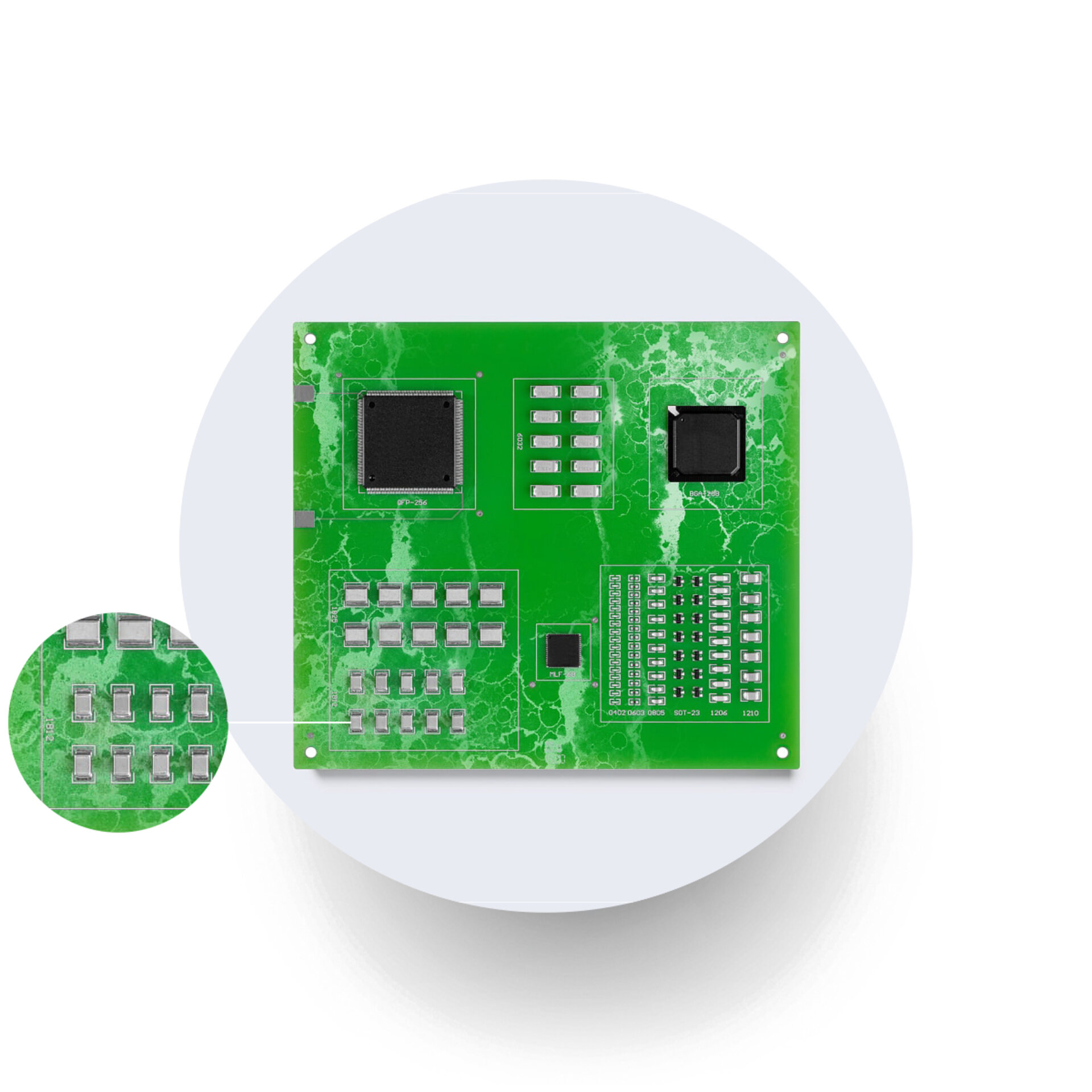

what is the ghosting phenomenon?A common consequence

of uncured solder mask on PCBs is the appearance of ghosting or white haze, particularly in areas where no flux is present. After tedious testing ZESTRON found the culprit of the haze to be uncured solder mask.

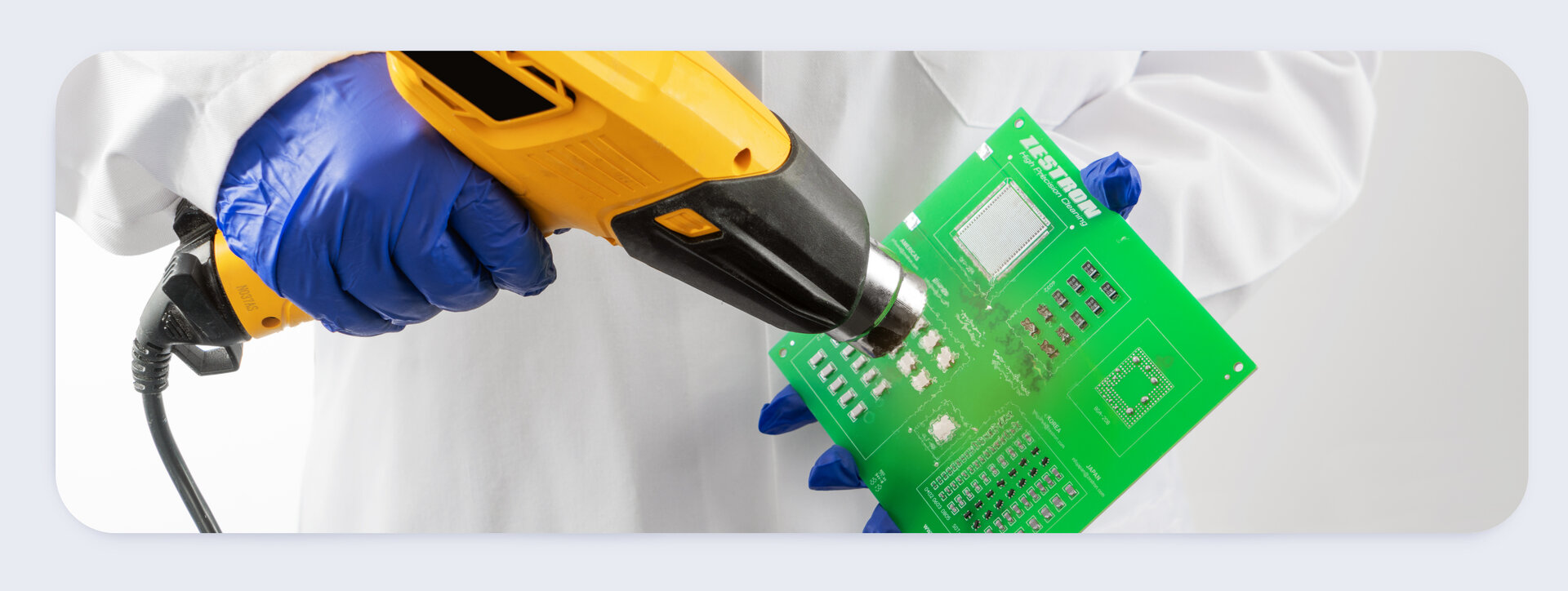

how do you know? try this quick testAre you seeing a white haze on your PCB? A simple test can be conducted to confirm if this is the result of uncured solder mask. Simply apply heat directly to the PCB using a heat gun , if the white residue or haze disappears, it indicates that uncured solder mask is the culprit.

To resolve the ghosting phenomenon

caused by uncured solder mask, the recommended solution is to bake the board at a high temperature of 150°C for 30 minutes. This thermal treatment facilitates the proper curing of the solder mask, eliminating the white residue or haze. However, if the problem persists even after heat treatment, it is advisable to seek professional assistance from experts such as ZESTRON, who can provide targeted troubleshooting for your specific issue.

So how can I avoid this?

Proper curing of the solder mask is paramount to ensure the integrity and longevity of PCBs. Uncured solder mask can result in electrical shorts, overheating, reduced solderability, and corrosion. Moreover, it can manifest as ghosting or white haze on the PCB surface. By understanding the consequences and employing appropriate measures, such as thermal treatment, manufacturers can address the issue of uncured solder mask and ensure the optimal performance of electronic devices.