06 | How Dangerous are Particles Especially When it Comes to High Voltage Applications?

Find out the critical impact of particles on high voltage electronic assemblies' reliability

get your answer

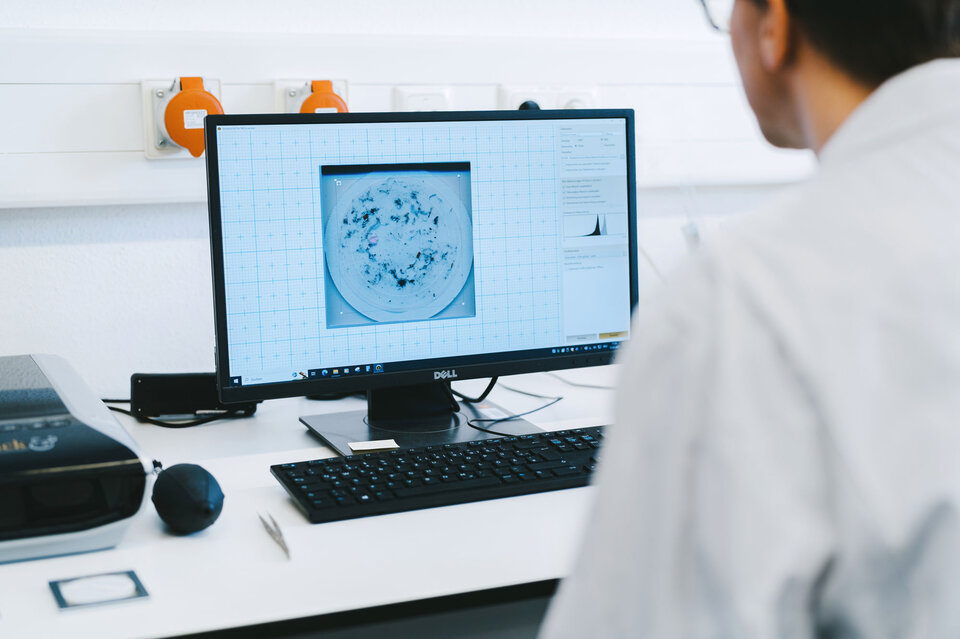

Particles can lead to malfunctions. But not every particle that is present on a PCBA’s surface is automatically considered as dangerous. In the video, Stefan Strixner explains why looking at the particle material is the key and how the actual risk for causing failures can be estimated.

video seriesMore Interesting Questions and Answers

01 | Why is High Voltage a Challenge for Insulation Coordination?

02 | How are Developers Challenged by High Voltage Systems?

03 | Which Failures Can Happen under High Voltage Stress?

05 | What Must Be Taken into Account When Coating High Voltage Assemblies?

07 | Is Insulation Coordination Also a Challenge for Electronic Control Units?

Technologie Coaching packagesHigh Voltage and Insulation Coordination: Achieving Optimal Results Together

Meet the requirements of high voltage and insulation coordination with our specially designed technology coaching sessions.