InsightsEfficiency and Reliability in E-Mobility

An innovative approach to minimizing failure risks in electric vehicle production.

E-Mobility Balancing Reliability and Cost Efficiency

The electric vehicle (EV) landscape is evolving rapidly. With growing demand for affordable and reliable vehicles, manufacturers face the dual challenge of balancing these two critical factors. At ZESTRON, we help you maximize the reliability of your electric vehicles without losing sight of cost efficiency.

EFFICIENCY MEETS RELIABILITY Overcoming Production Challenges

The reliability of electric vehicles is crucial for customer satisfaction and long-term market success. Manufacturers must ensure that their vehicles perform flawlessly under all conditions to avoid recalls and earn customer trust. This challenge is addressed through tailored production processes that minimize systematic errors and guarantee the long-term reliability of the vehicles. At the same time, cost efficiency must not be overlooked to remain competitive.

ZESTRON offers specially developed solutions to achieve this balance. By implementing targeted quality management practices, we help optimize production processes, identify and eliminate sources of error, and enhance both reliability and efficiency.

challenge Identifying Risks and Preventing Recalls

Electric vehicle manufacturers often face the challenge of preventing electrical failures in high-voltage areas. These issues are frequently caused by particle contamination or moisture ingress in OCB/DC/DC units, which can lead to costly recalls. Another risk lies in the lack of standardization, such as the IEC 60664 standard for electrochemical migration (ECM), which makes ensuring proper insulation in high-voltage areas more difficult.

In addition, failure mechanisms caused by aging processes often appear only at a later stage and can result in short circuits. This is where ZESTRON comes in: we provide tailored solutions that help OEMs address these challenges and avoid potential recalls.

Would you like to learn more? Contact us

innovative approachInnovative Solutions for Efficient and Safe Production

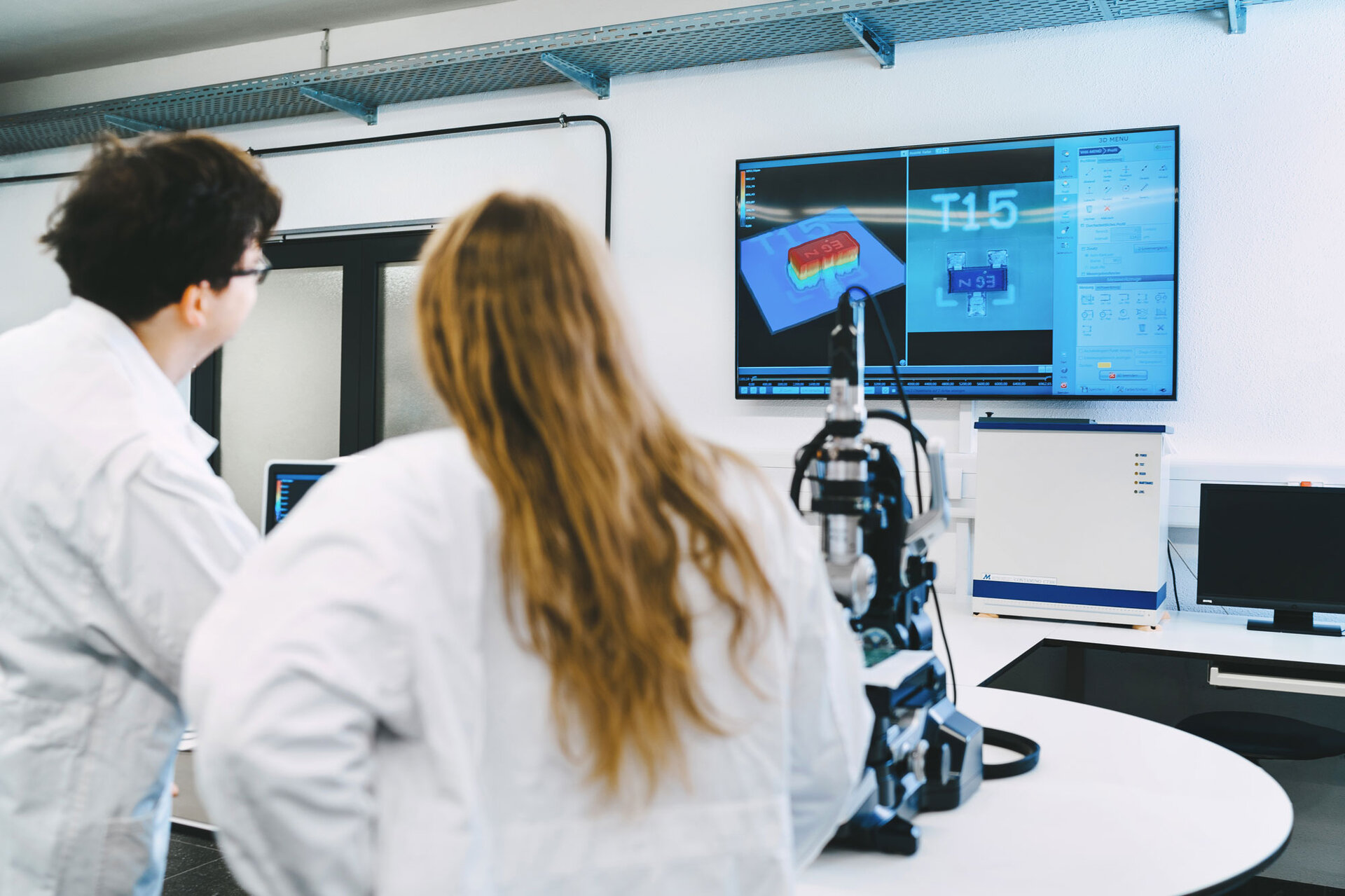

To identify potential failure risks before validation stress tests, ZESTRON uses accelerated high-voltage stress testing. These tests offer a novel analytical approach to insulation coordination, enabling critical sources of failure to be detected and resolved at an early stage. This not only improves reliability but also significantly reduces production costs.

Traditional measures such as establishing cleanrooms or implementing extensive monitoring along the production line can be reconsidered with this approach. It is worth evaluating whether more cost-effective alternatives—such as targeted cleaning processes along the production chain—can provide equally high reliability without unnecessarily increasing production costs.

Assistance ModulesYour Partner for Safe and Cost-Efficient Electric Vehicles

ZESTRON’s expertise in insulation coordination and accelerated stress testing helps you identify and eliminate sources of failure at an early stage. This not only saves costs but also ensures the high quality and reliability of your electric vehicles. With our assistance modules, we support you in successfully implementing these innovative approaches in your production and achieving long-term benefits.

Whether issues occur in the field or during the PPAP validation process, we provide fast and effective solutions. In addition, we train your teams to take appropriate measures already in the design phase to avoid potential failure risks as early as possible.

Whitepaper-CollectionAnalytical Approach to Implementing Insulation Coordination

At voltages from 400 V to 1200 V, standard tables are no longer sufficient. This white paper presents three key factors for analytical risk assessment – enabling well-founded decisions on pollution degree, system size, and weight.