InsightsThe Ideal Maintenance Cleaning Process - What do I Need to Consider?

Check your cleaning process for these factors - with a practical example

maintenance Cleaning / tool cleaningReliable Removal of Flux Residues and Outgassing

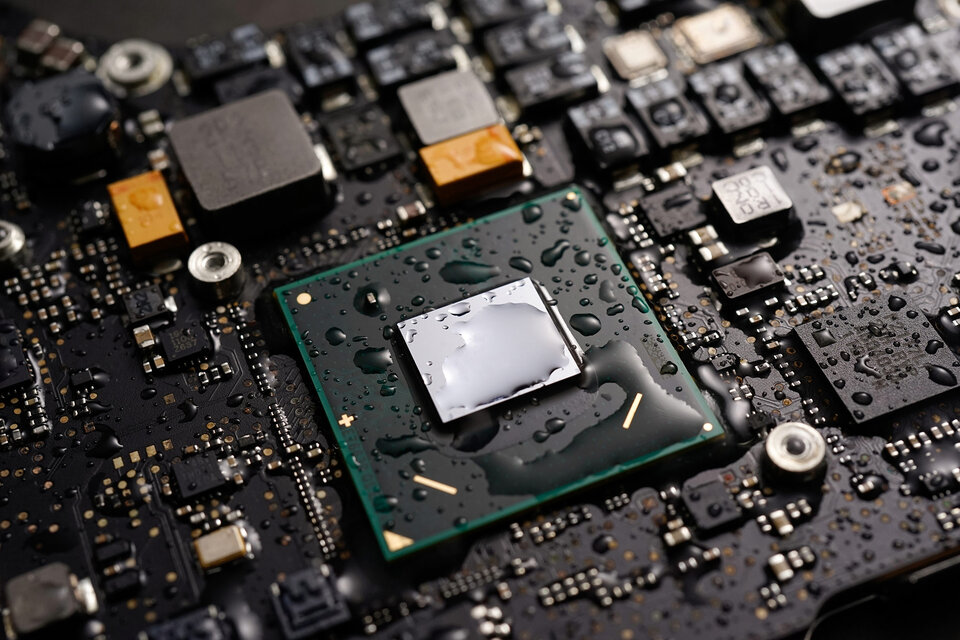

In the first part of our series on maintenance cleaning, we looked at why regular maintenance and tool cleaning is essential for the reliability of electronic components and which specific parts need to be cleaned. In this second part, we go one step further: we look at what requirements an effective maintenance process in electronics manufacturing should fulfil to ensure the maximum performance and service life of your devices.

maintenance cleaning / tool cleaningIdeal Maintenance Cleaning Practices in Electronics Production

In addition to a good cleaning performance, maintenance cleaning should fulfil 3 things in particular that you should check your cleaning process for:

1.

User-Friendly

First and foremost, the cleaning medium should not contain any harmful ingredients to ensure the safety of users.

If possible, the cleaning steps should be carried out mechanically in a cleaning system in order to achieve the best possible cleaning results and relieve the user. Manual rework should be avoided or reduced as far as possible.

2.

Cost-Efficient

An important factor is a long bath lifetime of the cleaning agent in the system. Frequent bath changes cause high labour and cost expenditure and, of course, high cleaner consumption.

In addition, the cleaner should be formulated in such a way that it is compatible with the material and does not attack any surfaces. This should maximise the service life of the tools and equipment used.

3.

Fast

It should be possible to load and unload the cleaning system and change the cleaning bath in a short time to minimise downtimes. Most maintenance work requires the production machines to be switched off, which costs valuable production time.

The cleaning process itself should also take as little time as possible. Putting tools in a cleaning bath for hours or days should be a thing of the past.

maintenance cleaningHow Often Should Maintenance Cleaning Be Carried Out in Electronics Production?

The question of how often maintenance cleaning should be carried out depends on your production throughput, individual requirements and, of course, the type and level of contamination.

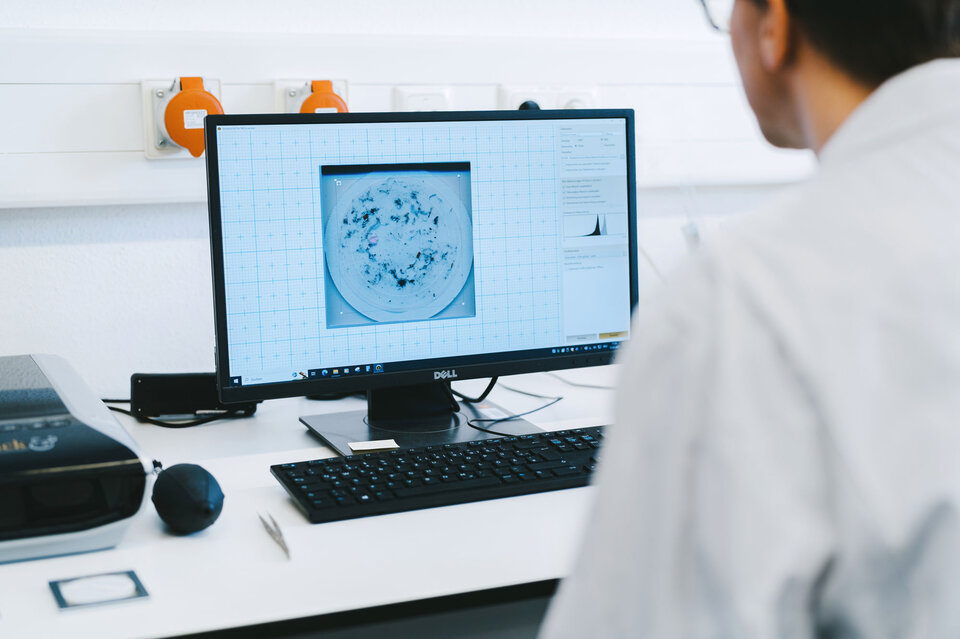

Automated Machine Cleaning

For reproducible and best possible cleaning results

Manual Cleaning

For permanently installed parts and interim cleaning

From practical experience Effective Maintenance Cleaning for Painting Frames - ATRON® DC

What does an optimised maintenance cleaning process look like in practice? Here we use a customer case to show how the use of the ATRON® DC decoater has achieved impressive results.

The Challenge:

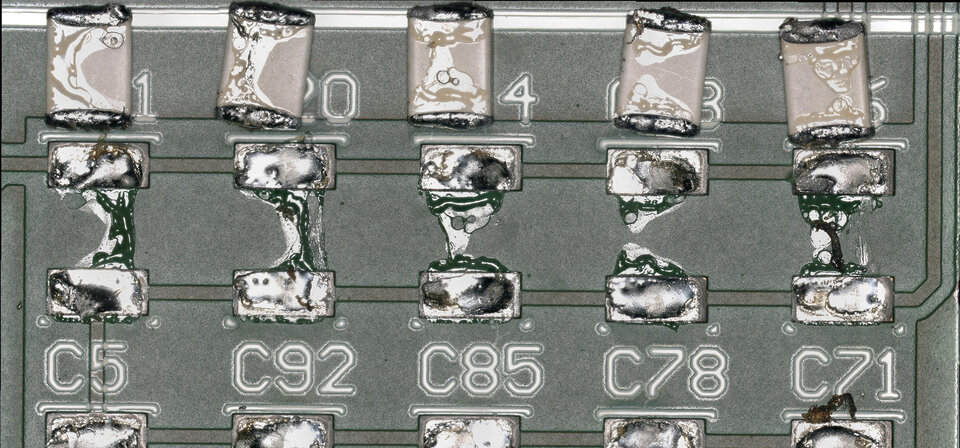

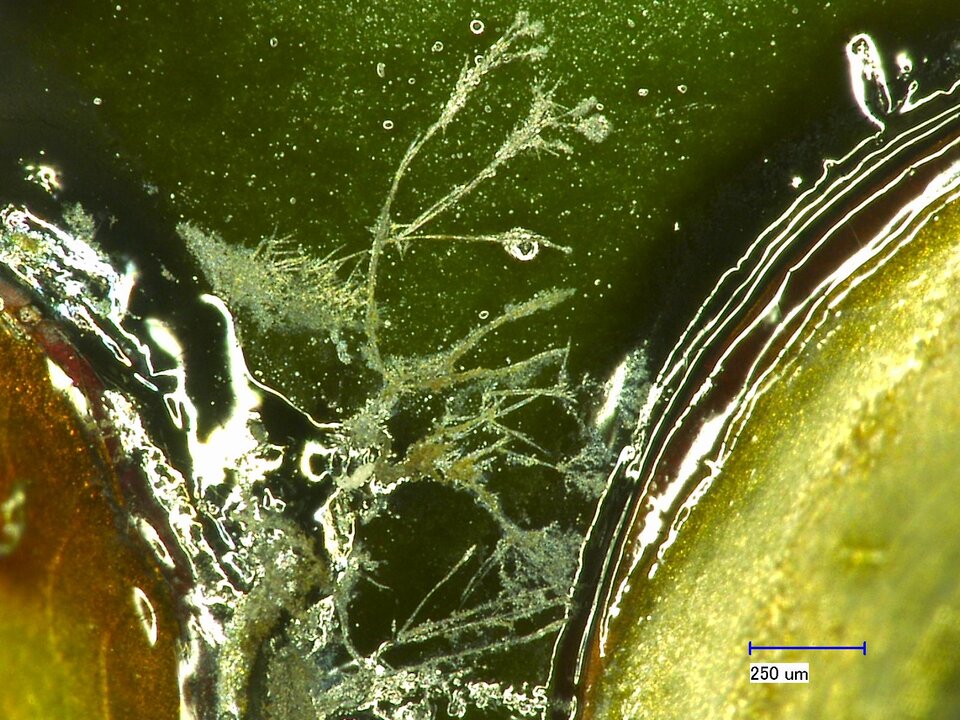

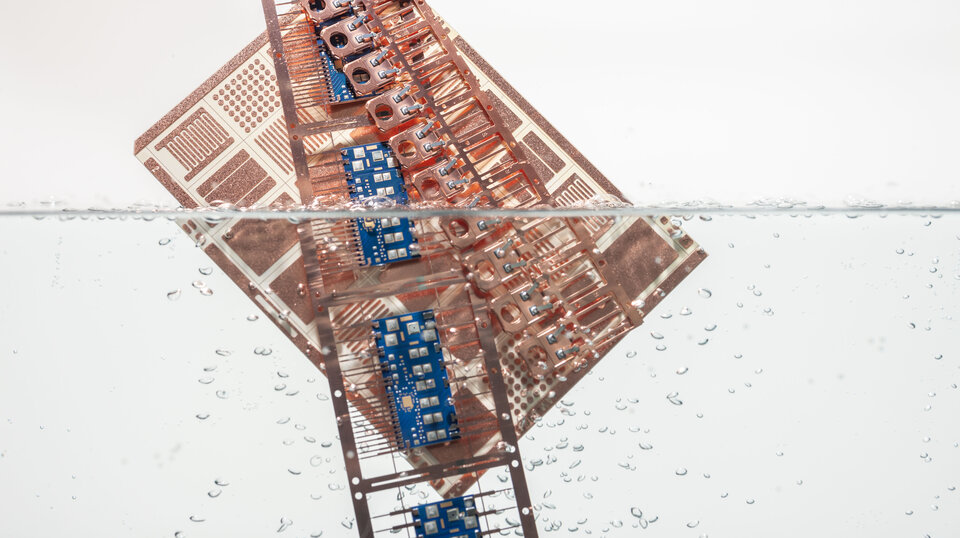

A customer from Northern Europe had the requirement to implement a new cleaning process for painting frames. Heavily dried residues of the HumiSeal® 1A33 paint were to be cleaned in an ultrasonic dipping process.

The Solution:

After intensive consultation and testing, the following process parameters were defined:

-

Cleaning Agent: ATRON® DC (water-based)

-

Cleaning Time: 90 minutes

-

Cleaning Temperature: 60°C

-

Ultrasonic Settings: 20 W/L & 45 kHz

-

Rinsing: Whit tap water at room temperature

-

Drying: Compressed air.

The Result:

After 90 minutes, the coating could be 100% removed in the process without manual rework. The water-based cleaner ensured a high level of user safety. The customer was very satisfied and implemented the process in their production.

Further Recommendations from ZESTRON:

Regular cleaning of the coating frames can reduce the cleaning time to 30 minutes. This not only shortens the cleaning time enormously, but also supports flawless conformal coating.

Do you have questions about cleaner selection or your process parameters? Are you looking for a new cleaning process for maintenance? Then we will be happy to help you.