SMT Cleaning – Comprehensive Solutions for Your Electronics Manufacturing

Tailored SMT cleaning for assembled PCBs, stencils, and tools

efficient cleaning of smt assembliesFor Optimized Processes and Reduced Costs

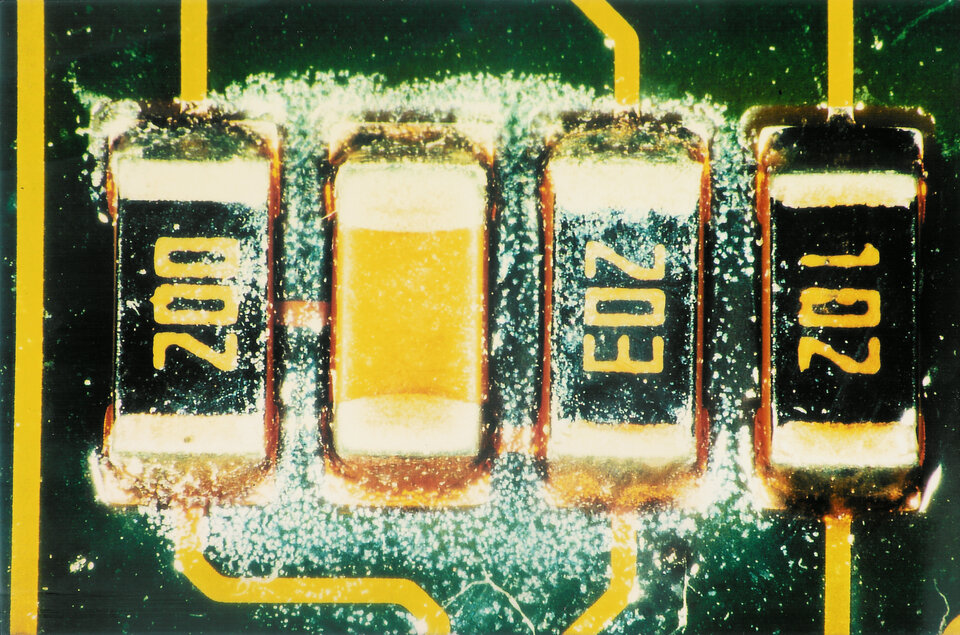

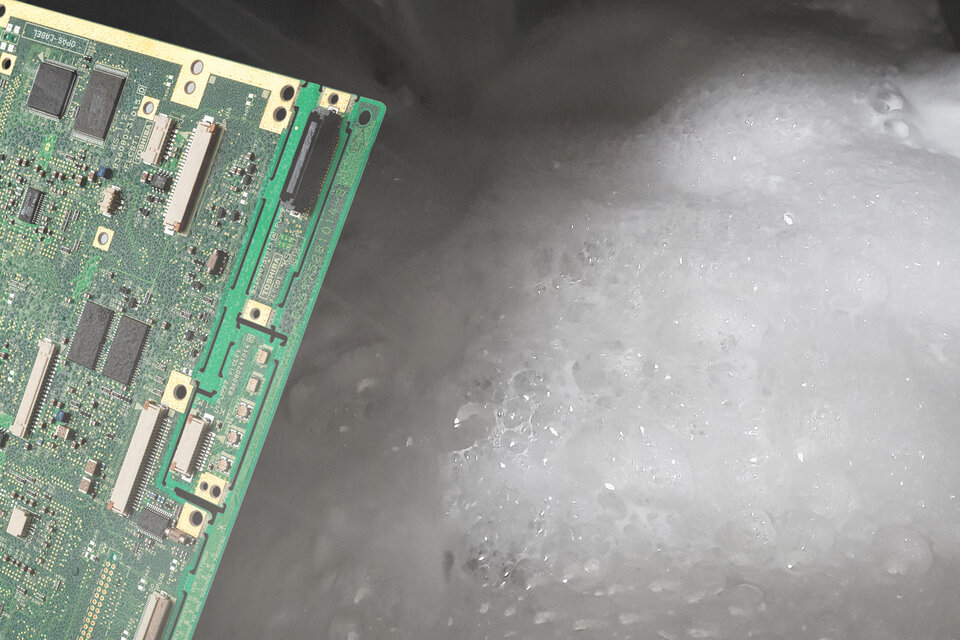

In electronics manufacturing, effective SMT cleaning is crucial for the quality and reliability of your products. Residues such as flux, solder paste, and adhesives not only impact the functionality of your assemblies but also lead to costly downtime and rework.

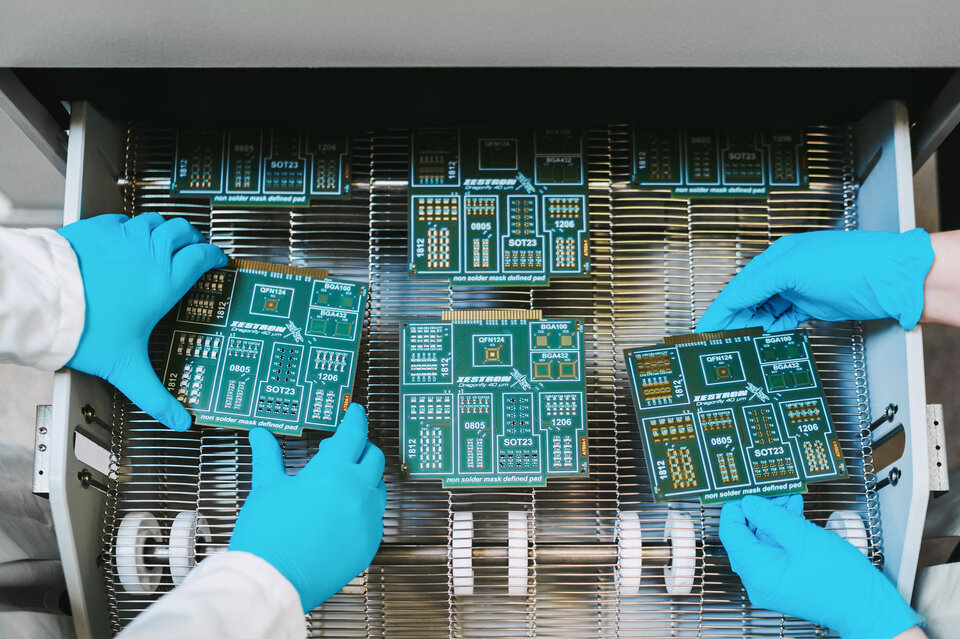

Our innovative SMT cleaning solutions optimize your production workflows, minimize defects, and enhance your competitiveness. We provide tailored solutions for assembly cleaning, stencil cleaning, and tool cleaning – ensuring maximum efficiency in your SMT manufacturing.

SMT assembly cleaningEnsuring Quality, Reliability, and Efficiency

SMT assembly cleaningEnsuring Quality, Reliability, and Efficiency

Professional assembly cleaning is the foundation for high-quality, reliable, and long-lasting electronics. By effectively removing production residues such as flux, solder paste, adhesives, and other contaminants, you can protect your products from corrosion, leakage currents, malfunctions, and premature failure.

Our cleaning agents also enhance the long-term stability of assemblies in no-clean processes.

Formulated for modern manufacturing processes, our cleaners ensure maximum efficiency and added value.

stencil & screen cleaning Precise Print Results for Your Electronics Manufacturing

stencil & screen cleaning Precise Print Results for Your Electronics Manufacturing

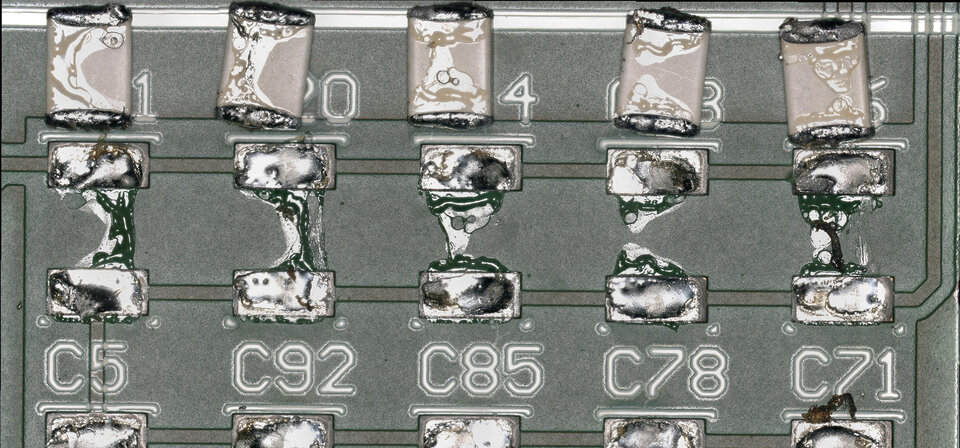

Stencil and screen cleaning is an essential process for ensuring high-quality print results. Residues from solder pastes, SMT adhesives, or thick film pastes can lead to poor print quality, clogged apertures, and damaged surfaces.

Our versatile cleaning agents thoroughly and gently remove these contaminants in both manual and machine-based cleaning processes.

Compatible with various materials and paste types, our cleaners ensure precise print results, high process stability, and an extended lifespan for your production tools, such as solder frames and carriers.

maintenance & tool cleaning For Long-Lasting Equipment and Smooth Processes

maintenance & tool cleaning For Long-Lasting Equipment and Smooth Processes

Comprehensive maintenance and tool cleaning are essential for the smooth operation and longevity of your production equipment. Stubborn residues such as flux, solder paste, adhesives, oils, and greases can impair performance, cause quality defects, and lead to costly production downtime.

Our cleaning agents effectively remove these contaminants from components such as solder frames, condensate traps, dispenser needles, reflow ovens, and soldering tips. This helps minimize downtime and rework while optimizing your production processes -flexibly applicable in both manual and machine-based cleaning.

efficient smt manufacturingYour Partner for Optimized SMT Production

Our experts analyze your specific requirements and develop comprehensive SMT cleaning solutions that seamlessly integrate into your existing workflows. Contact us for a personalized consultation and enhance both the cleanliness of your products and the efficiency of your production.